NaN / 0

PVC PE HDPE Snakeskin Pipe Clear Hose Transparent Soft Pressure Plastic Water Fiber Reinforced Garden Braided Hose Pipe Machine

Get Latest Price

US$ 26000

≥1 Sets

US$ 18000

≥2 Sets

Quick Details

Screw Design:

Double-screw

Screw L/D Ratio:

156:1

Screw Speed (rpm):

80 rpm

Place of Origin:

Jiangsu, China, Jiangsu, China

Product Details

Video Description

Product Description

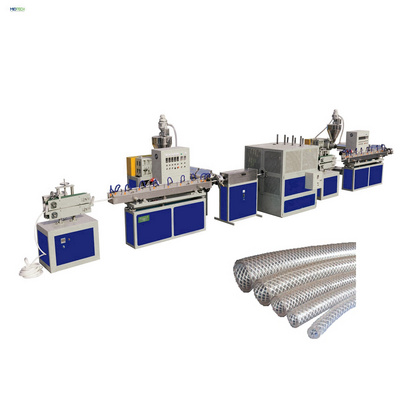

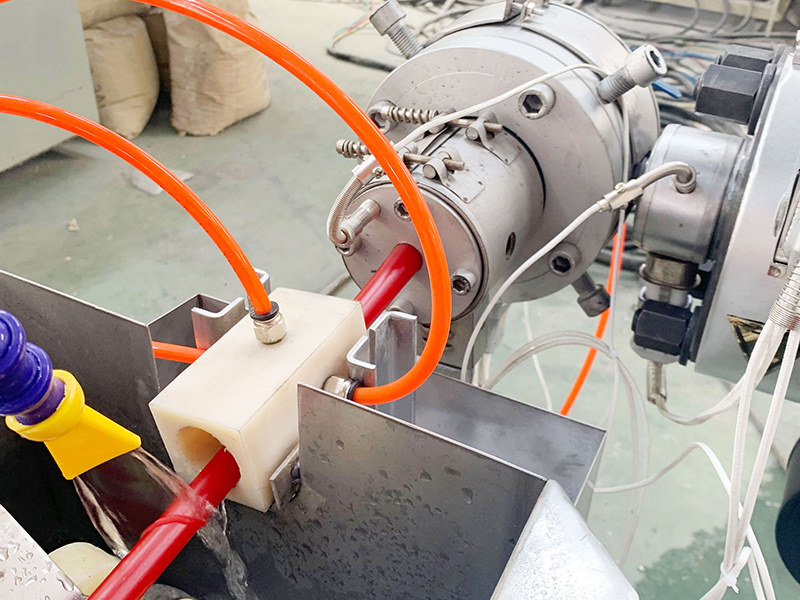

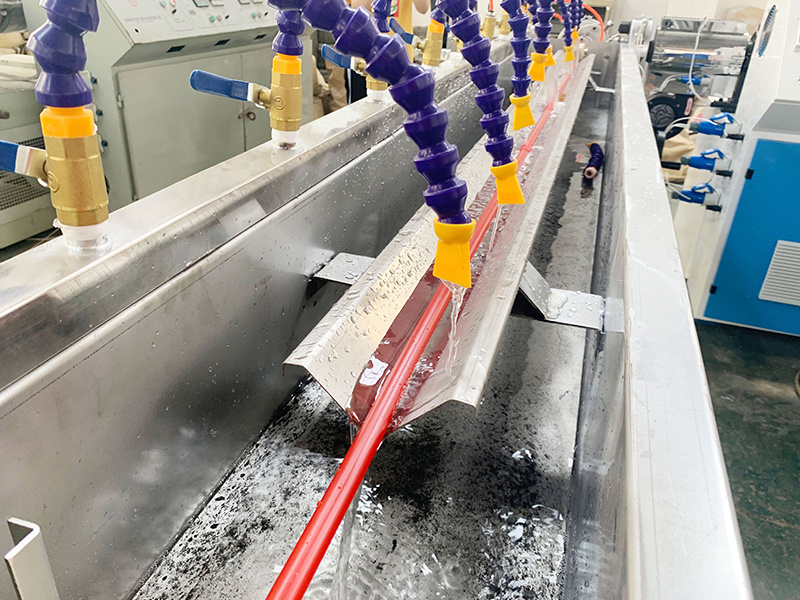

PVC FIBER REINFORCED PIPE EXTRUSION LINE

This unit is used for to produce PVC fiber reinforced hose, also named as PVC net hose, commonly called as snake hose. This

kind of soft hose is non-toxic, transparent, pressure resistance, tensile resistance, acid resistance, corrosion resistance,

beautiful

appearance, soft and lightweight, durable. Suitable for pressure corrosive gas, liquid transporting, widely used in machinery,

coal,

petroleum, chemical industry, agricultural irrigation, construction, civil (solar heater, gas tank etc) and other fields. Now also

used

in a large number of gardens, lawn watering.

Main Features of PVC Pipe Machine:

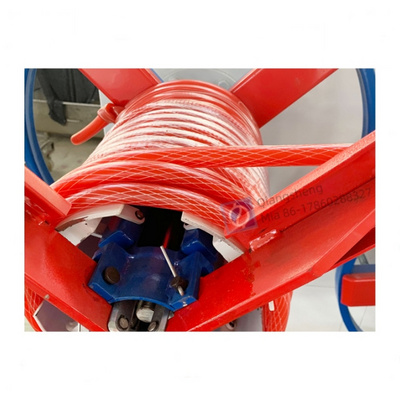

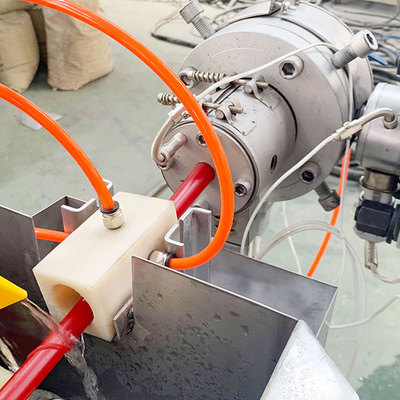

This line consists of main extruders, water cooling tank, haul off machine, fiber braiding machine, coiler etc, which has

reasonable design, unique structure, stable performance, easy operation and maintenance, constant production capacity, warmly welcomed by customers.Different models of production lines can produce PVC pipes with different diameter.

reasonable design, unique structure, stable performance, easy operation and maintenance, constant production capacity, warmly welcomed by customers.Different models of production lines can produce PVC pipes with different diameter.

Advantages:

It is mainly used in producing various diameters and wall-thickness of PVC pipes for aggriculture and constructional plumbing cable laying etc.

Our PVC pipe extrusion machine has features of low consumption, high output, stable running etc.

The standard PVC pipe extrusion machine include: material charger, SJZ series conic twin screw extruder, mould, vacuum calibration tank, spray cooling tank(for big pipe), haul-off, cutter, stacker.

Clients also can choose double/four PVC pipe extrusion line to make small size PVC pipes.

The main electrics for PVC pipe extrusion machine only adopt Siemens motor, siemens contactor, ABB inverter, Omron temperature meter.

All of our PVC pipe extrusion machine will be tested before delivery, and we will invite our cients to come and testing the whole line with us together.

Flow chart of PE pipe extrusion line:

Material →Heating Cooling Mixer →Material Feeding →Conical Twin Screw Extruder →Extrusion Mould & calibrator → vacuum Calibration Cooling Tank → (Spray Cooling Tank) →Printer → Haul-off Unit →cutter →stacker

It is mainly used in producing various diameters and wall-thickness of PVC pipes for aggriculture and constructional plumbing cable laying etc.

Our PVC pipe extrusion machine has features of low consumption, high output, stable running etc.

The standard PVC pipe extrusion machine include: material charger, SJZ series conic twin screw extruder, mould, vacuum calibration tank, spray cooling tank(for big pipe), haul-off, cutter, stacker.

Clients also can choose double/four PVC pipe extrusion line to make small size PVC pipes.

The main electrics for PVC pipe extrusion machine only adopt Siemens motor, siemens contactor, ABB inverter, Omron temperature meter.

All of our PVC pipe extrusion machine will be tested before delivery, and we will invite our cients to come and testing the whole line with us together.

Flow chart of PE pipe extrusion line:

Material →Heating Cooling Mixer →Material Feeding →Conical Twin Screw Extruder →Extrusion Mould & calibrator → vacuum Calibration Cooling Tank → (Spray Cooling Tank) →Printer → Haul-off Unit →cutter →stacker

|

|

|

|

|

|

The company's main products(Click Text)

PVC Pipe

PVC Fiber Pipe/Hose

PVC Foam Board

PE Pipe (Large Diameter)

PE Two-layers Pipe

3-Layers PPR Pipe

PE Corrugated Pipe

PP PE Two-stages Pelletizing

PP PE One-stage Pelletizing

PVC Hot-cutting Pelletizing

PP PE Water Ring Pelleting

PP PE One-stage Pelletizing

PVC Hot-cutting Pelletizing

PP PE Water Ring Pelleting

PVC Plastic Windows

PVC Ceiling

PVC Window Shutter

PVC Rain Gutter

PVC Corner

PVC Great Wall Panel

PVC Cable Trunking

PVC Ceiling

PVC Window Shutter

PVC Rain Gutter

PVC Corner

PVC Great Wall Panel

PVC Cable Trunking

Our Company

Zhangjiagang City Qiangsheng Plastic Machinery

2023 Shenzhen Chinaplas

Our company, Zhangjiagang City Qiangsheng Plastic Machinery , participated in the 2023 Shenzhen Chinaplas and Canton Fair, and will participate in every year in the future. Welcome friends who need to buy plastic machinery to communicate with us in a friendly way, hope to reach cooperation in the future.

Packaging and Shipping

Hot Searches