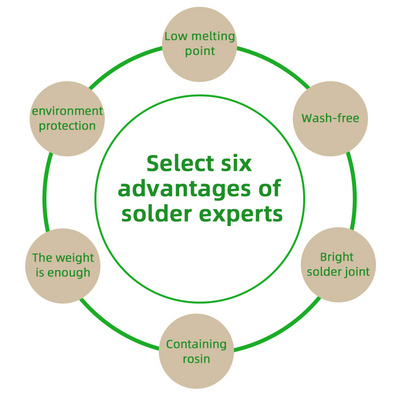

2. It is made of high quality pure white transparent hydrogenated rosin, free of cleaning, less residue, bright solder joint, less ion residue, clean and beautiful, high insulation resistance and high abrasion resistance;

3. International standard flux and vacuum sealing production process, good versatility, fast soldering, short wetting time, large spreading area, maximum solder activity, make copper and nickel welding materials used at the same time, greatly improve the use efficiency;

4. Environment friendly and tasteless flux, with fresh smell, less smoke, no reach controlled chemicals, no spatter during welding, less smoke and fresh smell;

5. Independent research and development and unique flux production process, the machine automatic solder smooth, no repair, as long as slightly adjust the proportion of rosin core, can be used for machine automatic solder, no tin, no repair

6.Reduce the thickness of IMC layer, make the solder joint strong and durable, strong mechanical resistance, and form a thin layer of transparent protective film on the surface of the solder joint, avoid the direct contact between the solder joint and air, keep the performance of the solder joint stable

7. One time drag welding with small spacing.