NaN / 0

Wholesale Original Quick 857DW+ SMD Rework Station Desoldering Station Hot Air Gun Heat Gun For Mobile Phone Repair

Get Latest Price

US$ 76

≥2 Pieces

US$ 67

≥80 Pieces

US$ 61.6

≥240 Pieces

Quick Details

Feature:

Temperature Adjustable

Rated Voltage:

220V/110V

Rated Output Power:

580W

Air Volume:

no

Product Details

Wholesale Quick 857DW+ SMD Rework Station Desoldering Station Hot Air Gun Heat Gun For Mobile Phone Repair

Product Description

Specifications:

1 Original Quick smd rework station

2 Automatic bga rework station

3 Soft revolving airflow

4 Automatic cooling system can increase the life of heating element and protect the unit

5 Factory price

6 LED digital display, LED number(resolving capability is 1℃)

| Brand | Quick |

| Model | 857DW+ |

| Power | 580W |

| Voltage | 110V 220V |

|

Airflow type |

Soft revolving airflow |

|

Capacity |

100L/min(max) |

| Unit Weigh | 3.1kg |

| OEM MOQ | 102PCS |

| nozzles | A1121 Φ:6.4mm |

| A1300 Φ:8.4mm | |

| A1301 Φ:12.7mm | |

|

A1124

Φ:2.5mm

|

Packing details:

1 Package: 8 pcs/ctn

2 Single box size: 30.5*17.5*23cm, weight: 3.1kg

3

Outer carton Size: 610*360*470 mm,

G.W: 10.5 kg / ctn

Characteristics:

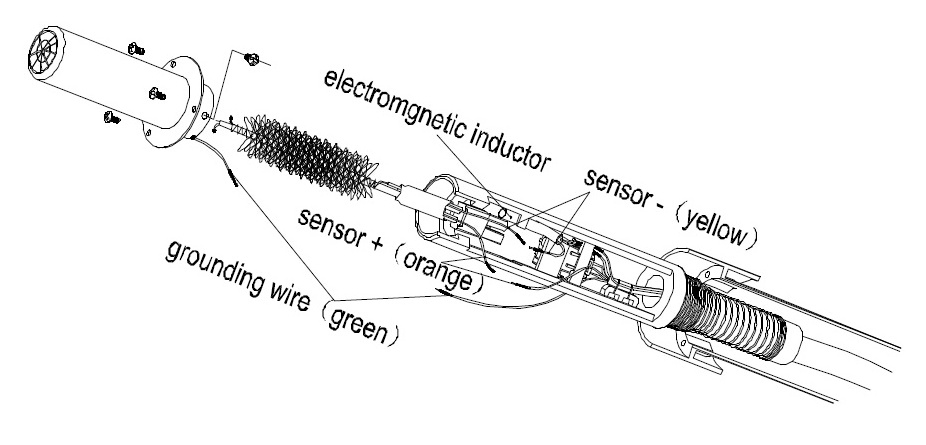

1. Closed loop sensor, temperature can be controlled by zero voltage triggering mode. Large

power and rapid heating. Temperature can be conveniently adjusted and the temperature is

accurate and stable, and not affected by airflow.

2. Stepless airflow adjusting with a wide range. Temperature can be conveniently adjusted.

3. Sensitive electromagnetic inductor in handle ensures the unit beginning working immediately

so long as the handle is held. When handle is put on the holder, the system will return back to

standby mode. Easy to use.

4. Automatic cooling system can increase the life of heating element and protect the unit.

5. Compact unit takes up little space on the workbench.

Operation

1. Put the unit on the workbench and put the handle on the holder. Connect well the power supply.

2. Install the nozzle on the handle. Select bigger caliber nozzle that fit with the IC.

3. Turn on the power switch. At the time, if the handle is on the holder, the unit will be in the sleeping state.

Analog Type:

(1) On the waiting (sleeping) state, the heating light is not bright.

(2) Setting the temperature by circumvolving the temperature-controlling knob.

(3) Take up the handle on the holder, and then the unit begins work and the heating light is bright.

(4) Adjusting the airflow by circumvolving the airflow-controlling knob.

(5) After finishing the work, take down the handle on the holder. After that, the unit cuts off the current to the heater

and then the unit begins to blow cooling airflow. When the temperature is less than 100℃, the unit

comes into the sleeping state.

Change and Fix the Nozzle

1. Select the appropriate nozzle that matches the size of the IC. Attach the nozzle when both the pipe and the nozzle

are cool.

2. Loose the screw on the nozzle.

3. Attach the nozzle on the steel pipe as shown in the drawing.

4. Fasten the screw properly

Replace the heating element

1. Remove the spring on the tube of the handle.

2. Loose the screws and slide out the steel tube. Remove the three screws that securely fasten the handle and then

slide the cord tube.

3. Disassembly the handle. Disconnect the ground wire sleeve and remove the pipe. In the pipe, the quartz glass

and heatinsulation is installed. Do not drop or miss it.

4. Remove out the heating element. Disconnect the terminal and remove out the heating element.

5. Insert a new heating element. Handle it with care. Never rub the heating element wire. Insert a new heating element

andreconnect the terminal. Reconnect the ground wore after replacing the element.

6. Assemble the handle in the reverse order of disassembly. Insert the handle’s protection into the

hole in the pipe.

Our Services

Certifications