NaN / 0

PVC pipe plastic extruding making machine/PVC water tube production line

Get Latest Price

US$ 150000

≥1 Pieces

US$ 75000

≥2 Pieces

Quick Details

Screw Design:

Double-screw

Screw L/D Ratio:

28:1

Screw Speed (rpm):

80 rpm

Place of Origin:

Shandong, China

Product Details

Product Description

UPVC/PVC-C Solid Wall Pipe Extrusion Line

PVC pipe extrusion line i s mainly used to produce PVC water supply and sewage pipe with the capable of producing pipes range from 16-800mm in diameter. Its unique structure design and high efficiency performance allows it fast adopted by pipe factories around the world.

Main technical parameters

| PIPE DIAMETER(MM) | 20-63 | 50-110 | 75-250 | 90-315 | 160-450 | 315-630 |

| MAIN EXTRUDER | 65/33 | 65/33 | 75/33 | 75/33 | 90/33 | 120/33 |

| EXTRUDER POWER(KW) | 37 | 55 | 110 | 132 | 160 | 280 |

| MAX CAPACITY | 120 | 180 | 330 | 380 | 450 | 750 |

Application UPVC/PVC-C Solid Wall Pipe Extrusion Line

The production line is mainly design, production for polyolefin pipe processing , and GF series pipe auxiliary machines can be used for other plastic processing too. Extrusion machine, GF series auxiliary machines are advanced, reliability , for the user to produce high quality plastic pipe provides a strong guarantee.

The production line adopts high efficiency single screw extruder, which is equipped with extrusion mould, vacuum forming tank, spray, haul off machine, planet cutting machine, PLC microcomputer control system.

UPVC/PVC-C Solid Wall Pipe Extrusion Line

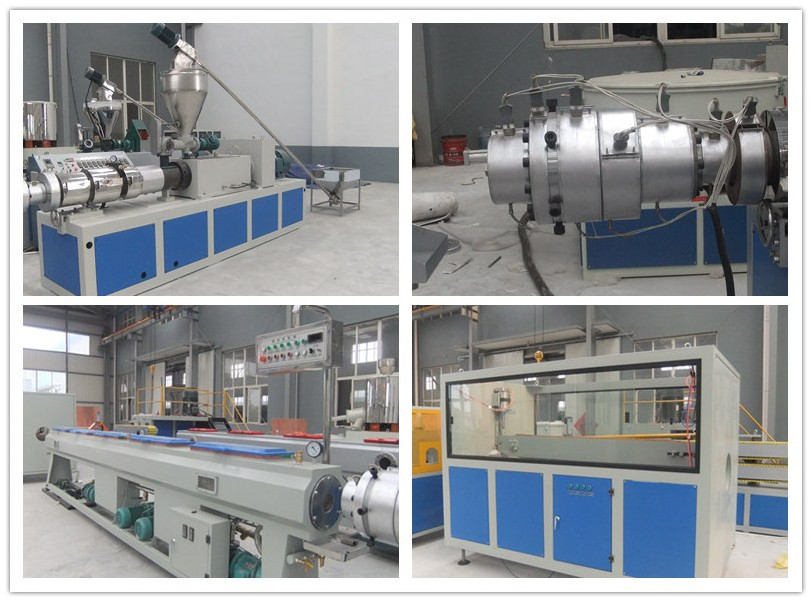

Detail show

l Conical twin-screw extruder;

l Mould;

l Vacuum calibration tank;

l Haul-off machine

l Cutter;

l Stacker

Packaging & Shipping

Our Services

The best service before and after delivery of the machine

|

1 |

Our company will provide relevant information on various technology and business consulted by customers. If clients want to visit our company, we will offer all they need for convenience. |

| 2 | After signing contract, company designs groundsill installation chart for water, electricity and gas of equ ipment basing on real condition and customers’ requirements and provides detail orde r list and matching manufacturer for reference for customer. |

| 3 | After equipment arrival, our service personnel will arrive at posted locale for installation, debugging, training and technology transfer till customers can operate independently and manufactures eligible product. Service personnel have to arrive at customer’s locale in time when we provide service for client again. |

Hot Searches