NaN / 0

Small Capacity 20 TPH Ore Rock Sand Stone Separating machine/Gold Washing Trommel Sand Gravel Mobile Trommel Screen for Sale

Get Latest Price

US$ 6500

≥1 Sets

US$ 1990

≥50 Sets

Quick Details

Type:

Sand and gravel separator

Place of Origin:

Henan, China

Brand Name:

MONA

Voltage:

380V/customized

Product Details

Introduction of sand and gravel separator

This sand and gravel separator is use to separate the fine sand and coarse sand. The advantage is simple structure, large workload, low cost and convenient maintenance, it widely used in construction, highway, sand farm, building material, mining and other industries.

This sand and gravel separator is use to separate the fine sand and coarse sand. The advantage is simple structure, large workload, low cost and convenient maintenance

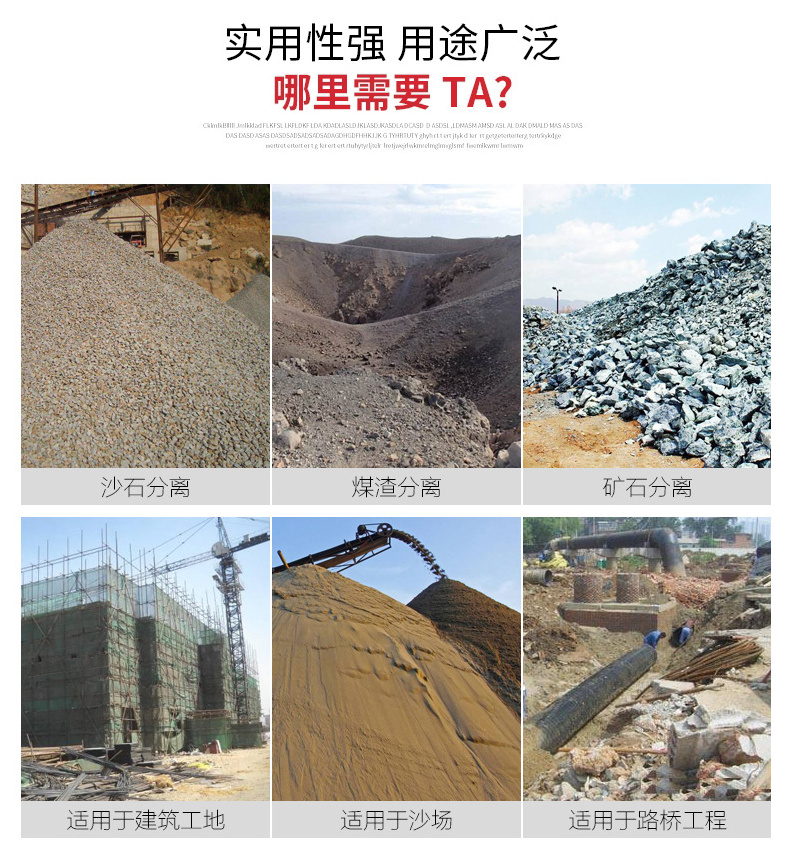

Application of sand and gravel separator

it widely used in construction, highway, sand farm, building material, mixing stations, road and bridge engineering,construction

sites, sand mining, coal yards, grain stations, etc mining and other industries.It is an ideal machine that saves manpower and

financial resources, improves project quality, speeds up project progress, and increases economic efficiency.

sites, sand mining, coal yards, grain stations, etc mining and other industries.It is an ideal machine that saves manpower and

financial resources, improves project quality, speeds up project progress, and increases economic efficiency.

Feature of sand and gravel separator

1.Simple installation foundation: Because the whole equipment is a box-shaped structure, only a flat ground is needed. The ground is hardened for easy cleaning. 2. High integrity: In addition to the finished material stacking belt conveyor, all systems are integrated in a whole frame, which not only ensures the integrity of the equipment but also leaves a moderate maintenance and inspection space. Convenience and safety. 3. Easy to disassemble and transfer: the high integrity of the equipment is convenient for storage or transfer on the construction site. The only disassembly and assembly parts are finished product belt conveyors, loosen the bottom fixing bolts and hanging wire rope, and plug the finished belt conveyor into the main frame Just the bottom. 4. Working reliability: The core screening system adopts the mixing principle of the mixer. The raw materials are continuously rolled, pushed and rubbed by the continuous spiral blades in the mixing drum. The effect is strong and reliable. 5. The rolling screen cylinder is placed horizontally, and the material flow rolls the screen for more than five times between the spiral blades of the screen cylinder, so that the sand material is repeatedly rolled and fully dispersed and screened. It is different from the phenomenon of incomplete sieving and mixing caused by the large and small materials squeezing each other or the large material tray small material vibration caused by the inclined roller screen or the inclined vibration screen.

Main parameter of sand and gravel separator

|

Model

|

MNSP-20

|

MNSP-30

|

MNSP-50

|

|

mesh size

|

1.5cm

|

1cm

|

1.5cm

|

|

Main motor

|

4kw

|

7.5kw

|

11kw

|

|

Mesh motor

|

2.2kw

|

4kw

|

4kw

|

|

Size

|

4.2*1.1*2.2m

|

8.5*1.6*3.2m

|

9.5*1.95*3.5m

|

|

Weight

|

800kg

|

1700kg

|

1950kg

|

|

Capacity

|

50quare/hour

|

60-80square/hour

|

150-200square/hour

|

|

Hopper

|

1.1*2m

|

1.5*3.2m

|

1.6*3.4m

|

|

Conveyor

|

0.5*8m

|

0.8*3m

|

1*18m

|

|

Vibration motor

|

0.5kw

|

0.5kw

|

0.5kw

|

|

Annular

|

4m

|

8m

|

9m

|

Picture shows of sand and gravel separator

FAQ