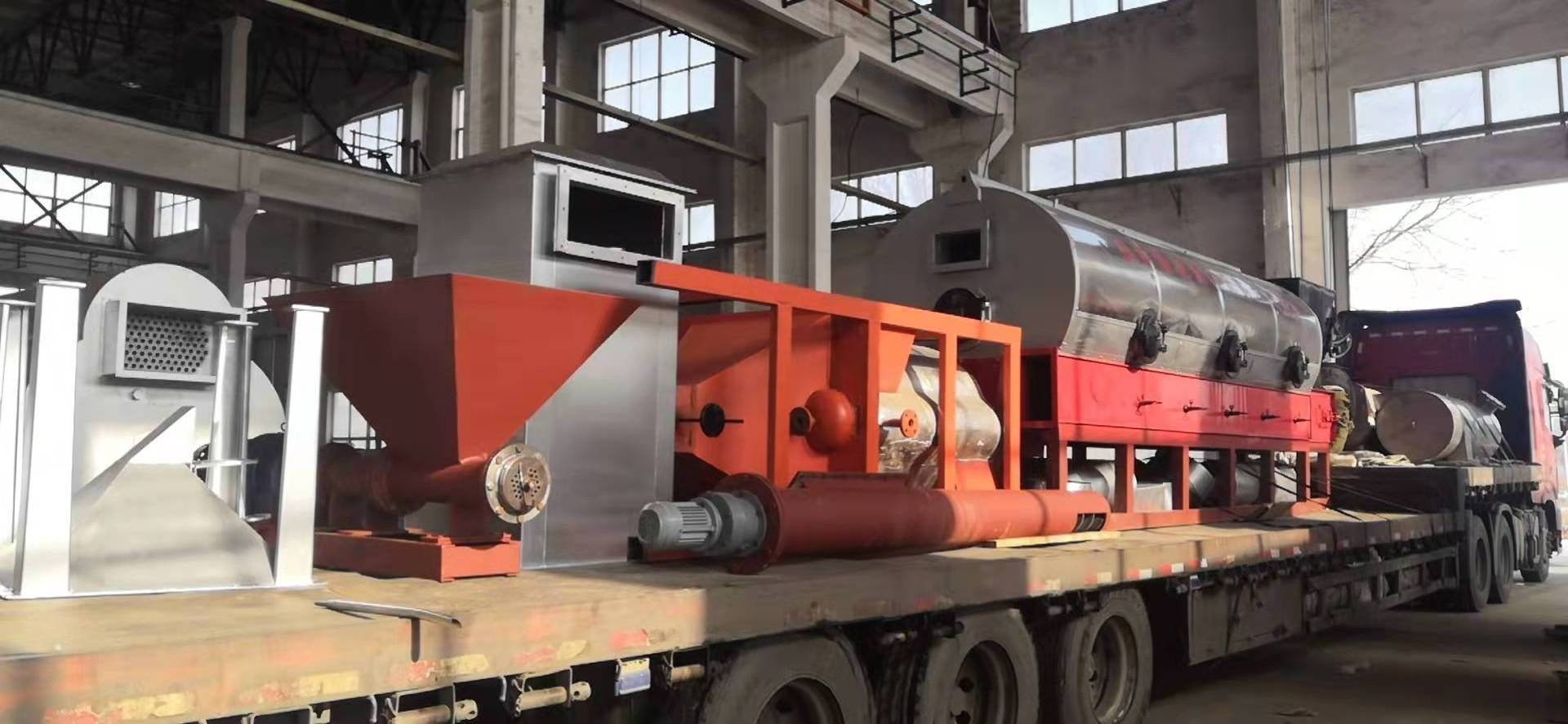

Dalian Sunshine Boiler Auxiliaries Co., Ltd is located in Dalian City. Our branch is located in Wafangdian City,is now one of the largest boiler auxiliary manufacturers in China.

Our company has

five workshops

and

three casting plant,

well-equipped,with various auxiliary components can ensure the casting.precision machining,welding equipment more than

200 sets

.Our company hhave been cooperated with tsinghua university.Peking University Peking University Professors for years to keep us in a leading position.