Description:

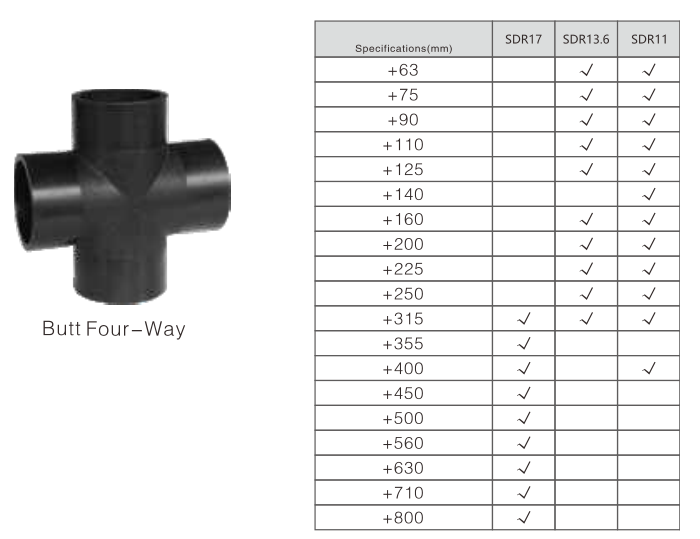

HDPE butt fusion fitting is one of three main methods of connecting the pipes, The consultant engineer will determine the pipe connection method according to the facilities available at the time of work in the specifications of the design. At the moment, the butt fusion connection is used for the main projects of HDPE piping and the flange connection is used for special fittings. PE butt fusion fitting will reached a solid connection to avoid leakage, on the other hand, compared with socket fusion fittings, the maxmum size of butt fusion equal tee can reached to 800mm and satisfy some projects which need large dimensions

Advantages:

The reason why HDPE pipe has become the most common solution for water supply, a reliable HDPE fittings play a important role, reasons as below:

* HDPE socket fusion fitting, HDPE butt fusion fittings & HDPE electrofusion fittings, are thermal plastic fittings. The pipeline and fittings can be welded together with a special welding machine to make pipe line leak-free and the same as pipe itself.

* There are different types of HDPE pipe fittings, like HDPE socket fusion fitting, HDPE butt fusion fittings & HDPE electrofusion fittings, compression fittings, thread fitting, etc. People can take the best choice based on their budget, construction environment.

* Safety of potable water: HDPE fittings are made of PE100 material, which is hygienic and suitable for portable water transportation.

* Resistance to corrosion, tuberculation, deposits: HDPE fittings are free to corrosive mediums.

* HDPE fittings can working under serious environment, like at extreme low temperature, no break.

* Long service life: HDPE fitting can support 50 years normal use.

* Recyclable, eco-friendly material: HDPE material is recyclable, and friendly to economic.

Applications:

1.Municipal water supply, gas supply and agriculture etc.

2.Commercial & Residential water supply

3.Industrial liquids transportation

4.Sewage treatment

5. Food and chemical industry

7. Replacement of cement pipes and steel pipes

8. Argillaceous silt, mud transportation

9. Garden green pipe networks