NaN / 0

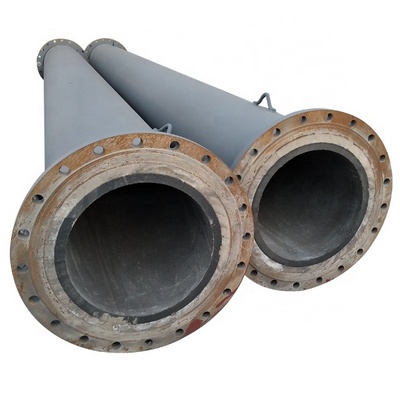

Anti-wear cast stone lined steel pipe / cast basalt lining composite tube

Get Latest Price

US$ 90

≥2 Pieces

US$ 50

≥100 Pieces

US$ 40

≥500 Pieces

Quick Details

Section Shape:

Round

Surface Treatment:

Painted

Tolerance:

±1%

Oiled or Non-oiled:

Non-oiled

Product Details

Anti-wear cast stone lined steel pipe / cast basalt lining composite tube

Product Description

1. Main Technical Data:

Technical Data of

Cast basalt lined steel pipe / bend / elbow

:

|

Items |

Index |

|

Alumina content |

12.52-13.52% |

|

Bulk Density |

≥3g/cm³ |

|

Vickers Hardness |

≥720kg/mm2 |

|

Compressive Strength |

≥600MPa |

|

Abrasive resistance |

≥0.07 g/cm2 |

|

Bending Strength |

≥60MPa |

|

Thermal Conductivity 20℃ |

20W/m.k |

|

Coefficient of Thermal Expansion |

8.92×10 -6 m/×m.k |

|

Modulus of Elasticity 20℃ |

1.67X 105 MPa |

|

Corrosion resistance |

Good |

Technical Datas of Steel :

Q235 steel plate for Normal Chemical Analysis (%):

|

Cr |

C |

Mn |

Si |

Other |

|

24%-30% |

4%-5% |

0.5%-2.5% |

0.5%-1.5% |

Less than 2% |

2. Brief Introduction:

Anti-wear cast stone lined steel pipe / cast basalt lining composite tube have an excellent performance of abrasive resistant and corrosion resistant, can be used as the pipeline lining in conveying wearable materials and corrosion materials.The combination of high rigidity of cast basalt ceramic and high elasticity of steel gives the pipe unmatchable features as an abrasion resistant, heat resistant and corrosion resistant material used in the variety of industries.Such as: electric power plant, chemical plant, metallurgy industry, mine and so on.

3. Manufacture Process:

4. Advantages:

1) Good abrasion resistance

As the wear surface, the cast basalt ceramic is 8 Mohs hardness, whose wear resistance is 10 times that of hi-chrome cast iron alloy pipes. It can make little wear loss of the pipe during running, which extend the service life of the equipment largely.

2) Good thermal stability and excellent corrosion resistance

-50-350 ℃ is ideal temperature for the cast basalt ceramic lined pipe, and the inner wall of the pipe is cast basalt plates or tubes which have unique chemical properties of wonderful acid and alkali resistance.

3) Light Weight

The density is 3.63g/cm³,which is only half of the steel to reduce the load of equipment largely.

4) Easy and fast to fix on site

Welding, flange, flexible joint are available for fix with the equipment.

All the performance of Anti-wear cast stone lined steel pipe / cast basalt lining composite tube makes low project costs, the charges can be about 20-30% less than wear steel piping project.

5. Normal Specification:

Full range of Anti-wear cast stone lined steel pipe / cast basalt lining composite tube including straight pipes, bends, elbows, tees,Y-pieces, reducers,crosses and etc can be available from our factory.

Regarding the connection ways, we can provide with the normal way of welding or flange or to customize according to the customer's requirements.

Regular size of the ceramic lined pipe:

|

Nominal Diameter |

100~800 |

Or we can supply design according to customer's requirements. |

|

Thickness of Wear-resistant Liner(mm) |

3~50 |

|

|

Thickness of Steel pipe |

4~8 |

Remark: Contact us for more sizes.

6. Application:

Anti-wear cast stone lined steel pipe / cast basalt lining composite tube are widely used for serious abrasive environments, such as chute liners, cyclone liners, conveyor skirt liners, processing piping liners, hopper or silo liners, screen equipment liners in the industries including ,but not limited to:

♦

Coal Preparation Plants

♦ Coal Fired Power Stations

♦ Mineral Processing Plants

♦

Cement Plants

♦

Chemical Plants

♦

Steel & Iron Plants

♦

Railway Stations

♦

Ports

7. More ceramic lined pipes:

Packaging & Shipping

Hot Searches