NaN / 0

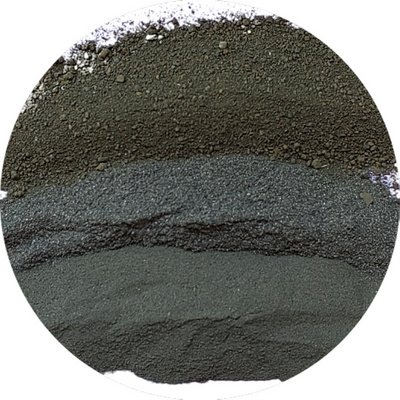

Best price Iron Ore polishing red iron oxide powder magnetite iron ore powder gas heater available for world wide users

Get Latest Price

US$ 250

≥1 Tons

Quick Details

Place of Origin:

France

Brand Name:

Ore

Model Number:

133545

Chemical Composition:

Fe203

Product Details

Iron powder is obtained by hydrogen reduction of ferric oxide. High temperature reduction is very strong, very lively nature. It is often said that the "flint". The common iron is iron powder.

Iron powder is obtained by hydrogen reduction of ferric oxide. High temperature reduction is very strong, very lively nature. It is often said that the "flint". The common iron is iron powder.

Reduction of iron powder is commonly used to say that the reduction method of iron powder, also known as reduction iron powder (Chun Tie)

A highly reactive iron powder, because of strong reduction, it is prone to oxidation, even in the air heating will burn slightly, because of its characteristic, often used for welding of rails, chemical reduction, prevent oxidative deterioration.

Main uses:

In addition, the addition of 10~70% iron powder to the electrode can improve the welding process of the electrode and increase the deposition efficiency significantly;

In the cutting of steel products, the reduction of iron powder into the oxygen acetylene flame can improve the cutting performance, enlarge the range of cutting steel, and increase the cutting thickness.

In the powder metallurgy industry, the total amount of 60%~80% is reduced, which is the largest consumption in the field of reduction iron powder;

Chemical reduction iron powder, mainly used in chemical catalyst, precious metal reduction, alloy addition, copper replacement, which is its most essential role.

Remove some of the most extensive use of more concentrated, there is our production of reduced iron powder can be used for reducing agent, can also be used to prevent preservative oil deterioration, which is a little more practical use in our daily life, there are some practical for you.

Hot Searches