NaN / 0

air conditioner recycling/scrap radiator recycling equipment in india/aluminium copper radiator scrap recycling machine

Get Latest Price

US$ 10000

≥1 Sets

US$ 9500

≥5 Sets

Quick Details

Place of Origin:

Henan, China

Brand Name:

HENGYI

Name:

aluminium copper radiator scrap recycling machine

Power:

45kw

Product Details

Product Description

Scrap Radiator Copper and Aluminum Separating Machine for Sale

Scrap Radiator Copper and Aluminum Separating Machine for Sale is a new product developed for processing waste radiators or heat sinks for recycle use. The Copper aluminum Waste Radiator Recycling machine can separate the copper, aluminum and iron through crushing and separation process. The separation rate can reach to 99.9%.

|

Detailed description of the recycling plant

The waste radiator is manually put into into the first crusher, the first crusher is doubt shaft shredder,the radiator is squeezed, torn, broken into 5CM width, and the length is uneven,strip type radiator, the broken material is transported to the second crusher through discharge conveyor, and the second crusher adopts a heavy hammer crusher to smash the radiator into a sheet, and then under the belt magnetic separator of the conveyor, the iron in the material is sorted, and the remaining copper and aluminum will be transported to air sorting machine by conveyor. The sorting machine has 2 outlets, No. 1 outlet is a heavier mixture (copper and a small amount of aluminum) and the No. 2 outlet is lighter pure aluminum. The material of the No. 1 outlet is then transported by a conveyor to a specific gravity sorting machine for fine sorting, to sort the remaining copper and aluminum.. The dust collected in the first crusher, second crusher, magnetic separator and conveyor is collected by the high pressure fan to the pulse dust collector, and there is a dust outlet under the pulse dust collector, which is discharged to the storage box by the screw conveyor.

Application

|

The radiator before separating

|

The products(copper,aluminum,iron) after separating

Detailed flow chart of waste copper aluminum recycling plant

|

Main products

| 1 .Shredder | |||||

| Model |

Power (KW) |

Capacity (KG/H) |

Blade Number |

Blade Dia (mm) |

|

| BS-500 | 7.5*2 | 400-600 | 16 | 220 | |

| BS-600 | 11*2 | 600-800 | 24 | 220 | |

| BS-800 | 22*2 | 800-1000 | 32 | 220 | |

| BS-1000 | 45*2 | 1000-1300 | 40 | 220 | |

| 2 .Hammer crusher | |||||

| Model |

Power (KW) |

Capacity (Tons/H) |

Total Size (MM) |

Weight (Ton) |

|

| SRQ-700 | 45 | 2 | 3050*2100*2700 | 5 | |

| SRQ-900 | 55 | 3 | 3050*2300*2700 | 6 | |

| SRQ-1200 | 132 | 5 | 4200*2708*3475 | 10 | |

| SRQ-1400 | 200 | 8 | 4880*2510*4290 | 15 | |

| 3 .Magnetic separator | |

| Separate the iron/steel after the waste radiator be crushed by the hammer mill | |

| 4 .Gravity separator | |

| Under high pressure wind different materials have different density and it will affect the distance of horizontal movement by this way to realise the sorting purpose. | |

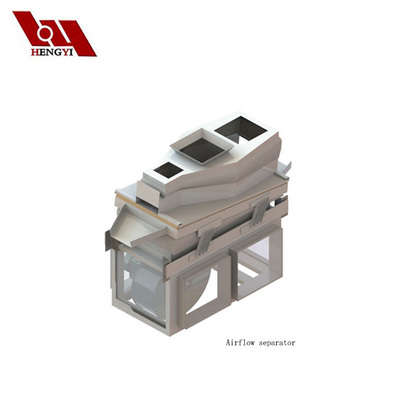

| 5 .Air flow separator | |

|

The Airflow separator is also a specific gravity soring method. The materials of similar size and different specific gravity have different weights. Through the joint action of the blower and the induced draft fan and the sieve bed which reciprocates at the bottom. The heavier and lighter materials are respectively selected from the discharge ports at the front and rear ends,Thereby achieving the purpose of sorting. Widely used in copper & plastic,aluminum & plastic,copper & aluminum and other materials with large differences in specific gravity. |

|

Advantage

>>1. The entire production line uses the PLC automated control system to achieve coordinated work between the equipment, stable feeding and operation.

>>2. Simple structure, reasonable layout, strong processing capacity, stable operation, firm and durable, safe and reliable.

>>3. Coarse crushing uses the biaxial shredder with low rotating speed and large torque, and the cutter and shaft are specially treated with alloy materials.

>>4. The entire set of equipment uses the negative pressure induced air pulse dust removal system to ensure a good working environment

Our Services

Pre-sale Service

(1) According to the customers' special requirements, provide the most suitable project design, process design and the purchase program.

(2) Guide customers to choose the best and economical plant, recover investment within short time, and site inspection.

On sale service

(1) Welcome you to our factory for a visiting;

(2) Accompany you to check our machine production, quality and the working conditions.

(3) Customize the equipments strictly according to your special requirements and arrange the timely delivery.

After-sale service

(1) Installation guidance

When the machine arrives at your company, we will dispatch our technicians to your factory to guide the installation and commissioning at site.

(2) Technical training

We provide free technical training service to your stuff. Training content contains the main work principle of machine, operating regulations, maintenance methods and steps, safety, etc.

(3) Warranty

Three guarantees of our product quality, warranty for one year (not include man-made damaged). We will maintain the machine for free for the quality problem. If the damage is caused by your improperly operation, the cost of the maintenance burden by you. we also provide you the life-long follow-up service.

Hot Searches