NaN / 0

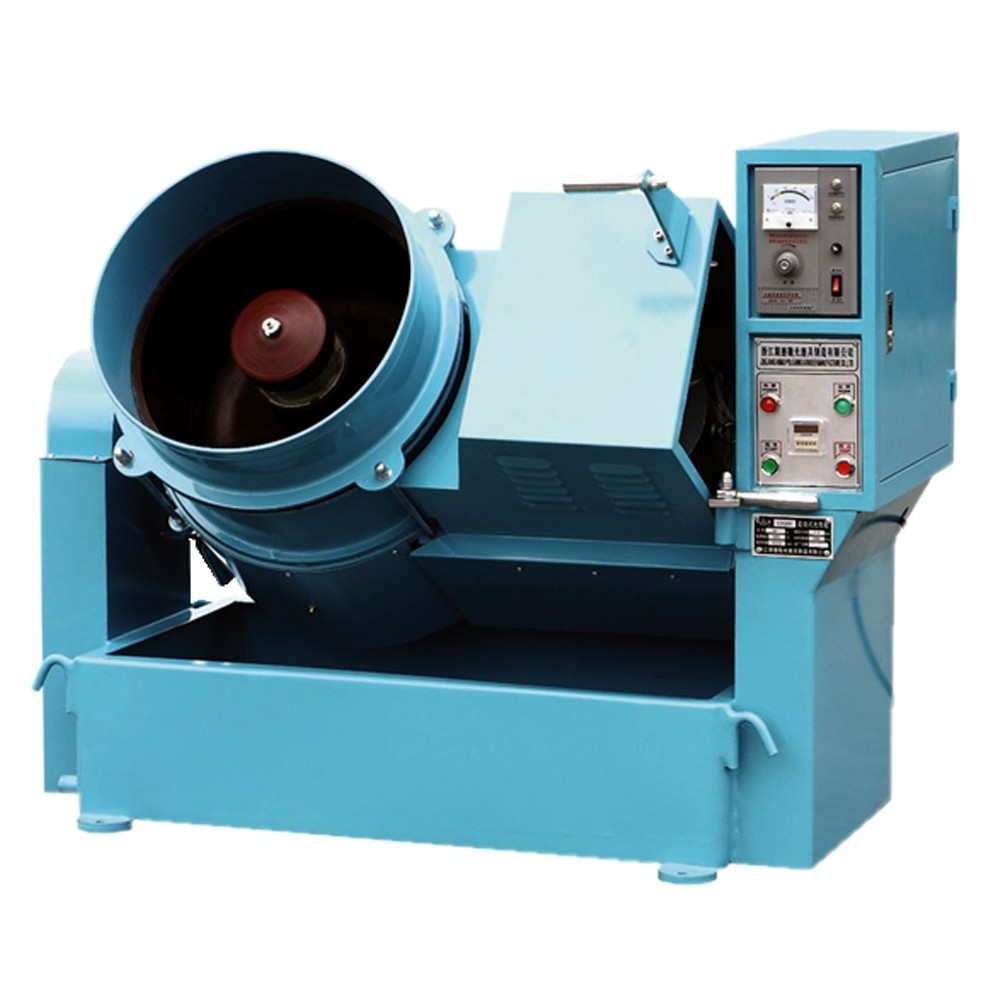

50L 120L large capacity centrifugal disc polishing machine / finishing machine high speed eddy current finishing machine

Get Latest Price

US$ 3800

≥1 Pieces

US$ 3500

≥3 Pieces

US$ 3000

≥10 Pieces

Quick Details

Place of Origin:

Zhejiang, China

Brand Name:

MX-120L

Power (kW):

3

Weight (KG):

1200

Product Details

HONG HAO MACHINE

Parameters of eddy-light finishing machine:

Vortex type buffing finishing is a new type of barrel grinding method. The drum is composed of a fixed cylinder wall and a rotary bottom plate. During the process, the rotary chassis rotates at a certain speed, so that the mixture of the workpiece and the processing medium produces a spiral vortex motion. And it produces a strong barreling effect, achieving the purpose of evenly removing the workpiece burrs, chamfering and polishing.

1.12 The inner pu grinding groove can generate strong eddy current friction movement, the rolling force is large, and the finishing efficiency is high.

2. Electromagnetic speed regulation and frequency conversion speed regulation can make the turntable infinitely variable speed at 50-220 rpm.

3. A wide range of processing capabilities are available, and the processing cycle is easy to automate from feeding → water supply → barreling → drainage → separation → washing → discharging.

4. Low noise, no vibration, no splash of working fluid, so that the working environment is improved.

This machine can be widely used in various industries such as metal, plastic, ceramics and other stamping parts, machined parts, castings and forgings, heat treatment parts and other parts of the deburring, chamfering, derusting, descaling, polishing and other processes In particular, it provides the most ideal finishing equipment for complex shapes and thin deformable parts.

120L Centrifugal disc polishing machine / finishing machine

Product Description

Product Application

Our company is specialized in producing and saling polished polisher, shot blasting machine, polishing abrasive, abrasive, grinding as one of the complete sets of manufacturing,fiting for products and machinery, electronics, instrumentation, aerospace, motorcycle, daily hardware, handicrafts , Metal, non-ferrous and non-ferrous metal surface finishing finishing, including deburring, flash, round, in addition to oxide, rust, strengthen the metal surface, bright polishing, plating and chemical treatment Before the surface finishing treatment. Especially for some can not afford the greater mechanical pressure of thin-walled, narrow, thin parts, shaped complex cavity of the finishing process, play the role of industrial beauty! Our company is strong in technology, advanced equipment, especially in recent years ,we put into the gas furnace and sintering tunnel and drying tunnel equipment so that our polishing abrasive abrasive production even more powerful, the daily output of up to 20 tons, to achieve the computer temperature control, greatly To ensure the long-term stability of product quality! Products are exported to Europe and the United States and other countries and regions in the industry in a leading position! The main products: vibration series of polisher, planetary series of polisher, eddy current series of polisher, series shot blasting machine, hot air centrifugal dryer and a variety of rolling with the abrasive, abrasive, grinding fluid.

Eddy current machine

Eddy current type abrasive finishing, variable speed motor or the rotating frequency converter stepless speed change, lined with PU glue polygonal groove, eddy current friction movement of strong operation, so as to achieve uniform workpiece deburring, chamfering or polishing purpose.

WE HAVE TWO SIZE,ONE IS 50, one is 120L

Main Features

Its features are as follows:

1, rolling grinding force, high processing efficiency.

2, the selection of a wide range of processing capacity.

3, easy to realize production automation.

4, low noise, no vibration, no working liquid splash, so that the working environment has been improved.

5, the use of the original principle of vortex flow, the efficiency of the whole light, improve the efficiency of 15~30 times.

6, according to the need to choose the speed of the turntable, easy to operate, you can spot the workpiece processing.

7, the fixed slot and the turntable lining with poly ammonia rubber, high strength, good wear resistance, service life extension

Our Brand

Our factory

quality best

price: cheapest

Original: china

Voltage:220v,380v

we had saled to peru,mexico,poland,Portugal, Russia, New Zealand, Ecuador, Malaysia, Spain

Domestic famous engines, strong driving force, low fuel consumption, high economic benefits 12F+4R sliding sleeve shift.

Our Service

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine with video

* if need Engineers available to service machinery overseas.

our mexico General agent--rafael

also can contact our rafael office ,if you are in mexico markets or near markets.

Packing & Delivery

Related Products

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

Hot Searches