NaN / 0

powder coating bicycle frames powder coating bicycle frames(plasma spray machine,powder coating)

Get Latest Price

US$ 7000

≥1 Sets

Quick Details

Place of Origin:

Guangdong, China

plasma spray:

ceramic coating

coating:

iron, nickel & cobalt based alloys,Titanium alloys,ceramic

easily operate:

light.

Product Details

Product Description

Introduction: powder coating bicycle frames powder coating bicycle frames(plasma spray machine,powder coating)

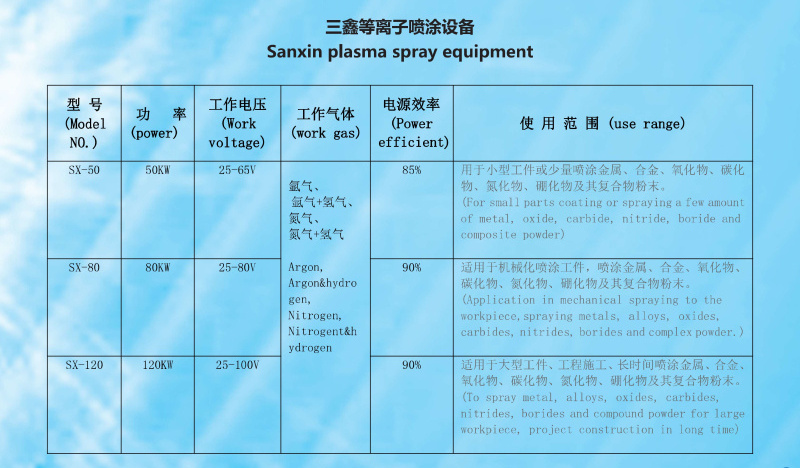

SX plasma series is designed for top quality thermal spray coating solution, not only metal and alloy coating, but also ceramic coating.

Model. SX-50 plasma spraying system utilizes Argon / Hydrogen / Nitrogen as working gas. Its comparatively low power will be suitable for applying metal, iron, nickel & cobalt based alloys, ceramic, carbides, cements, oxide and other composite powder on small components or small area with minimum energy consumption. It makes up the disadvantage of other alternative thermal spray technologies that can not apply ceramic material. PS-plasma spraying series are the best solution for needs of both metallic and ceramic high quality spray coating in one system.

Model. SX-80 is popular system in medical industry because its application of spraying titanium nitride coating. Smart Thermal Spray Plasma's system is designed for top quality thermal spray coating solution. PS-80 plasma spraying system utilizes Argon / Hydrogen / Nitrogen as working gas. Besides of titanium alloy, it can also apply iron, nickel & cobalt based alloys, ceramic, carbides, cements, oxide and other composite powder on workpieces and component. It makes up the disadvantage of other alternative thermal spray technologies that can not apply ceramic material. PS-plasma spraying series are the best solution for needs of both metallic and ceramic high quality spray coating in one system.

Model. SX-120 is suitable for special industrial coatings like thermal barrier coating, implant titanium and hydroxyapatite coatings. Also it is suitable for applying metal, iron, nickel & cobalt based alloys, ceramic, carbides, cements, oxide and other composite powder. PS-120 plasma spraying system utilizes Argon / Hydrogen / Nitrogen as working gas. Its comparatively high power allows it to apply on bigger workpieces, large component and bigger area for long time of non-stop working. The PS – plasma spraying series make up the disadvantage of other alternative thermal spray technologies that can not apply ceramic material. It’s the best solution for needs of both metallic and ceramic high quality spray coating in one system.

Packaging & Shipping

Product information

1. Assembled with branded top quality and reliable parts such as Siemens PLC monitor & touch screen, SMC electromagnetic valve, air operated valve, Omron pressure pickup, Schneider electrical switching, Kewill flow valve, etc.

2. Powder feeder with precise adjustment of the feeding speed

3.Strong and durable control cabinet

4.Urgent stop button for safety

5.Customized Brand name / Logo available

6.Equipped with long-lasting and easy-to-use SX-80 Plasma spray torch

Typical coatings that can be applied are:

Iron, nickel & cobalt based alloys,

Titanium alloys

Different kind of ceramic,

Hydroxyapatite

carbides,

cements, oxides and other composite powder

Properties of the coatings can be :

High hardness

Long-lasting

High temperature resist

Oxidation resistant

Anti Wear

Sliding, abrasives , erosion resistant

Chemical (Acid / Alkaline, etc.) resistance

Applications:

Due to its uniqueness of spraying technology, SX- plasma series can be used in many areas that require heat resistance such as exhaust system in racing cars. Also with the excellent longevity produced by plasma thermal coating equipment compared to other spray method, it's popular in bio-compatible implants coatings such as hip, knees, dental implant parts coating with hydroxyapatite and titanium alloy material in health and medical industry as well as blades and vanes, solid oxide fuel cells, and combustion chambers in other industries.

Contact Info

Skype: bermanhk

Whatapp / Mobile: +86 135 3322 3230

WeChat: 89995318

E-mail: thermalspray86#gmail.com (# repaired @)

Offical Web: http://www.sx-spray.com

Youtube: https://www.youtube.com/channel/UChtnCZL7KnF_p4Dxz8b9dgg

Our company has rich experience of manufacturing and construction applications more than 34 years in thermal spray field . We can provide a full set of technical support, including the best cost-effective equipments, onsite construction services , solution and process and any other support you need.We also recruit agency in different area

We also provides diversified services

(1)Diversified thermal

(2)Spraying Equipment and coating

(3)Intelligent production line

(4)New coating service

(5)Soundproof room standard

(6)Power Boiler Global Construction

(7)Aerospace coating

(8)Medical coating TI HA

(9)Pulverizing system

(10)Auto parts anti-wear insulation

(11)Coated silicon aluminum target manufacturing

(12)Import and export equipment

(13)Raw material selection

Thermal Spraying for Ministry of Water Resources, Electric Power, Intelligent production line, Power Boiler Global Construction, Aerospace coating, Medical coating TI HA, Pulverizing system, Auto parts anti-wear insulation, and Coated silicon aluminum target manufacturing etc.

Our Services

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Other Main Thermal Spraying Equipments and Service:

(1) HVOF spray equipment

(2) Arc spray equipment

(3) Vacuum Plasma Spray Machine

(4) Sputter Target Produce Equipment and technology

(5) Precious metal vacuum coating equipment

(6) Cooker magnetism and thermal conduction coating spraying production line Thermal

(7) Industrial water chillers

(8) Spray Coating Services

(9) Electro Brush Plating Equipment

(10) High power flame spray plastic equipment

FAQ

Question

:What's the use of your machine?

Answer

: Our machine is for surface treatment.

Question

:Do you offer the training for the machine operation?

Answer

: Yes,we do,we can offer the training for free.

Question

:Do you offer the coating service besides machine?

Answer

: Yes ,we do,we can offer the coating service around the world,we can spray the workpiece in our factory or send people to where you are.

Our machines are very professional ,in order to help you get the best solution ,please kindly reply the following technical questions.

1.What kind of product will you want to spray ?

---

Could you provide some pictures?

2. What is the working conditions for your product ?

---

What is the PH and temperature ?

3. What kind of material will you want to use? --- aluminum wire,zinc wire or tungsten carbide powder ,ceramic powder or some others?

4. Which effect will you want to get ? --- high temperature resisting ,wear resisting or anti corrosion ,repairing work or others?

5. Do you have any other technical requirements?

---

the more the better.

Spray Coating Application Cases

Hot Searches