NaN / 0

Spiral Gravity Chute Concentrator Machine Price Mineral Copper Gold Ore Concentrator Processing Production Plant

Get Latest Price

US$ 2000

≥1 Sets

US$ 1200

≥5 Sets

Quick Details

Place of Origin:

Jiangxi, China

Brand Name:

MingXin

Voltage:

220V/380V

Weight:

800 KG

Product Details

Product Description

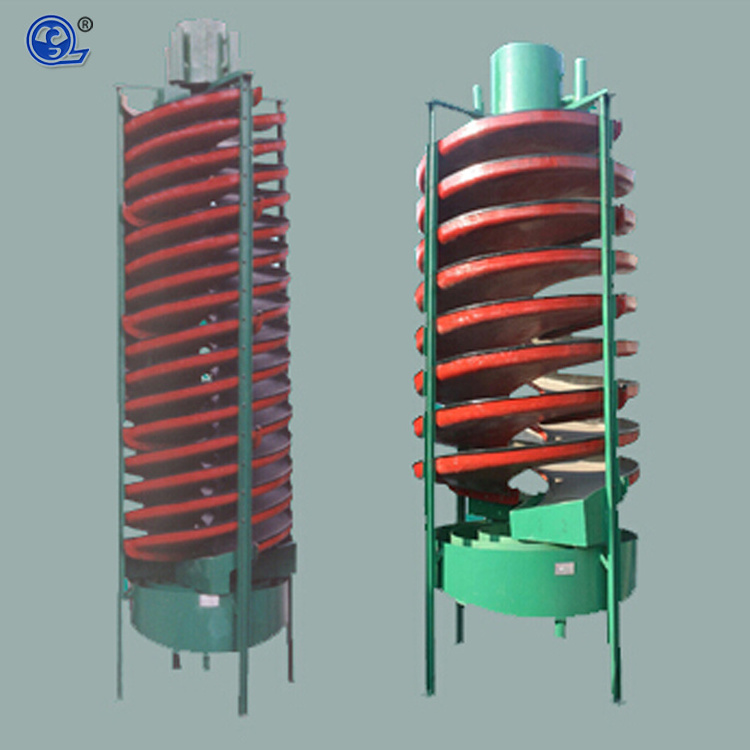

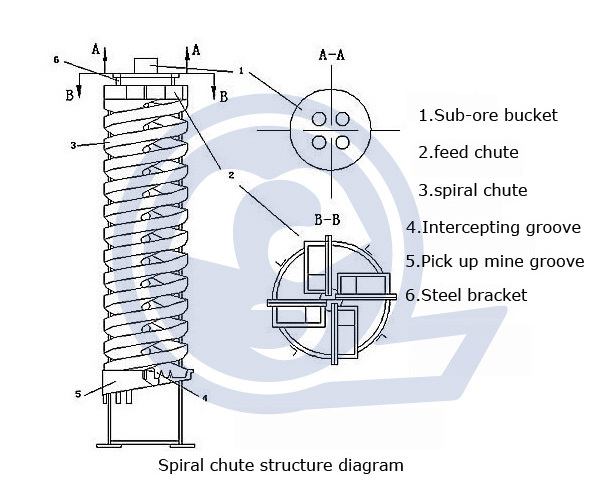

The glass fiber reinforced plastic rotating spiral chute is made by rotating the chute on the basis of the fixed spiral chute.

The device structure is shown in the figure below.

The spiral groove body is made of aluminum alloy, double layer (head), driven by the lower transmission mechanism to rotate slowly along the flow direction of the pulp.

The cross section of the groove is cubic parabolic, elliptical or oblique straight, the groove surface is covered with rubber lining, and there are grid strips or triangular grooves arranged obliquely with the diameter of the spiral.

Slight vibration of the groove surface during rotation and enhanced centrifugal force.

It promotes faster zoning of ore feeding, obvious difference in the movement trajectory of light and heavy minerals, and the sorting effect is better than that of ordinary fixed spiral chute or spiral concentrator.

The enrichment ratio is high, the effective separation particle size range is 0.6-0.05 mm, and the lower limit of particle size recovery is slightly higher than that of the spiral chute.

The glass fiber reinforced plastic rotating spiral chute is made by rotating the chute on the basis of the fixed spiral chute.

The device structure is shown in the figure below.

The spiral groove body is made of aluminum alloy, double layer (head), driven by the lower transmission mechanism to rotate slowly along the flow direction of the pulp.

The cross section of the groove is cubic parabolic, elliptical or oblique straight, the groove surface is covered with rubber lining, and there are grid strips or triangular grooves arranged obliquely with the diameter of the spiral.

Slight vibration of the groove surface during rotation and enhanced centrifugal force.

It promotes faster zoning of ore feeding, obvious difference in the movement trajectory of light and heavy minerals, and the sorting effect is better than that of ordinary fixed spiral chute or spiral concentrator.

The enrichment ratio is high, the effective separation particle size range is 0.6-0.05 mm, and the lower limit of particle size recovery is slightly higher than that of the spiral chute.

Application of Spiral Chute:

Spiral chute concentrator is widely used to the separation for mineral particles, the size of which ranges from 0.3 to 0.02 mm. it can be suitable for dealing with different kinds of ores, such as below:

-Rutile, ilmenite and zircon concentration.

- Iron ore, chromite and manganese beneficiation.

-Tin, tantalum and ore concentration.

-Gold, native copper and base metal recovery.

-Silica sands processing.

-Titano-magnetite concentration.

Parameters

| Model | BLL-2000 | BLL-1500 | BLL-1200 | BLL-900 | BLL-600 | BLL-400 |

| Outter dia(mm) | 2000 | 1500 | 1200 | 900 | 600 | 400 |

| Spiral distance(mm) | 1200 | 720,540 | 900,720,540 | 450,360,270 | 450,360,270 | 240,180 |

| Spiral distance ratio | 0.6 | 0.48,0.36 | 0.75,0.6,0.45 | 0.6,0.45 | ||

| Gradient (°) | 9° | |||||

| Max. Screw Numbers Per Set | 3 | 4 | 4 | 4 | 2 | 2 |

| Feeding size(mm) | 2.00-0.04 | 0.8-0.037 | 0.3-0.03 | 0.3-0.03 | 0.2-0.02 | 0.2-0.02 |

| Mine density (%) | 30-55 | 25-55 | ||||

| Capacity (t/h) | 7-10 | 6-8 | 4-6 | 2-3 | 0.8-1.2 | 0.15-0.2 |

| Outside diameter(mm) | 2120 | 1600 | 1360 | 1060 | 700 | 460 |

| Heigh (mm) | 5600 | 5300 | 5230 | 4000 | 2600 | 1500 |

| Weight(Kg) | 900 | 800 | 600 | 400 | 150 | 50 |

Hot Searches