NaN / 0

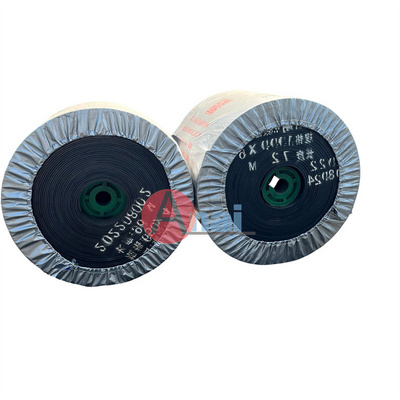

Abrasion Resistant Ex-Factory Price Ep Rubber Conveyor Belt

Get Latest Price

US$ 7

≥50 Meters

US$ 5

≥100 Meters

Quick Details

Processing Service:

Cutting, Splicing

Place of Origin:

Hebei, China

Brand Name:

TRX

Model Number:

TRX-EP

Product Details

Portable Belt Conveyor RAM1 Standard Belt Multi-Ply Ep Conveyor Belting

Product Description

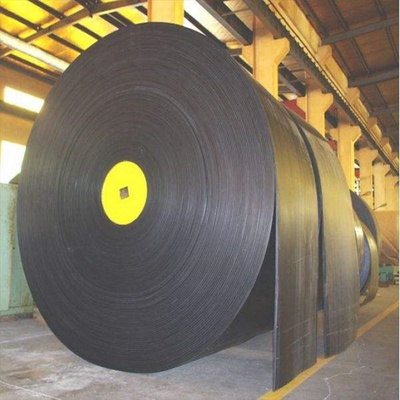

EP rubber conveyor belt

is widely used by the mining and processing industries for transporting bulk or lumpy materials such as quarrying, ore, coke, aggregates, crops, sand, clinker, chemicals, construction materials, etc.

The EP is short for Polyester fabric, which includes polyester toward longitudinal(warp) and polyamide for latitude(weft), EP fabric plies are sandwiched between rubber skim coats for adhesion and load support. Bottom and top cover compounds are added for maximum protection of the belt carcass. The EP conveyor belt consisting of two to six EP fabric plies, EP rubber conveyor belt has the same merit as Nylon conveyor belt, in addition, EP fabric has the advantages of:

A.Lower longitudinal elongation.

B.Full resistance to mildew, moisture and rotting.

C.Good flexibility and trough ability.

D.Short take-up lengths.

E.Suitable for middle and long-distance transportation of higher load and speed.

Polyester / Nylon Conveyor Belts (EP / PN Carcass) : Polyester Warp / Nylon Weft

Product Parameters

Our technicians / equipment are trained to manufacture belts as per:

DIN 22102 (German), AS 1333 (Australian), SABS (South African), RMA (US, South America), BS 490 (British), JS (Japanese)

| DIN-22102 | ||||||

| Grade | TensileStrength(MPA) | Elongation at Breaking |

Abrasion (≤mm3)

|

Adhesive strength betwee Plies(N/mm) | Adhesive strength between | |

|

Bottom Cover (0.8-1.9mm) |

Top Cover (≥1.9mm)

|

|||||

| W |

18 |

400 | 90 | ≥5 | ≥3.5 | ≥ 4.5 |

| X | 25 | 450 | 120 | |||

| Y | 20 | 400 | 150 | |||

| Z | 15 | 350 | 250 | |||

| DIN-22102 | ||||||

| Grade | TensileStrength(MPA) | Elongation at Breaking |

Abrasion (≤mm3)

|

Adhesive strength between Plies(N/mm) | Adhesive strength between | |

|

Bottom Cover

|

Top Cover (≥1.9mm)

|

|||||

| A |

18 |

400 | 90 | ≥7 | ≥5 | |

| X | 25 | 450 | 120 | |||

| M | 24 | 450 | 150 | |||

| N | 20 | 400 | 250 | |||

| AS1332-2000 | ||||||

| Grade | TensileStrength(MPA) | Elongation at Breaking |

Abrasion (≤mm3)

|

Adhesive srength betweePlies(N/mm) | Adhesive strength between | |

|

Bottom Cover (0.8-1.9mm) |

Top Cover (≥1.9mm)

|

|||||

| A |

17 |

400 | 70 | ≥6 | ≥4 | ≥ 4.8 |

| E | 14 | 300 | / | |||

| F | 14 | 300 | / | |||

| M | 24 | 450 | 125 | |||

| N | 17 | 400 | 200 | |||

| S | 14 | 300 | 250 | |||

| S* | 12 | 300 | 250 | |||

| Carcass | fabric type | Strength per ply (N/mm) | Thickness per ply (mm) | Cover Thickness (mm) | No.of Ply | Belt Width (mm) | Length per Roll (m/Roll) | |

| Top Cover | Bottom Cover | |||||||

| NN | NN100 | 100 | 0.70 |

3 3 3.2

4 4.5 4.8

6 6 6.4

7.9 8 9.5

|

1.5 3 1.6

2 4.5 1.6

2 6 3.2

3.2 4 3.2

|

2-10 |

300-12000 |

20-100 |

| NN125 | 125 | 0.70 | ||||||

| NN150 | 150 | 0.75 | ||||||

| NN200 | 200 | 0.90 | ||||||

| NN250 | 250 | 1.15 | ||||||

| NN300 | 300 | 1.25 | ||||||

| NN400 | 400 | 1.50 | ||||||

| EP | EP100 | 100 | 0.75 | 2-8 | ||||

| EP125 | 125 | 0.75 | ||||||

| EP150 | 150 | 0.85 | ||||||

| EP175 | 175 | 0.85 | ||||||

| EP200 | 200 | 1.00 | ||||||

| EP250 | 250 | 1.20 | ||||||

| EP300 | 300 | 1.35 | ||||||

| EP350 | 350 | 1.50 | ||||||

| EP400 | 400 | 1.65 | ||||||

| EP500 | 500 | 2.00 | ||||||

| CC | CC56 | 56 | 1.10 | 3-12 | ||||

| Minimum recommended Pulley Diameters | Pulley Dia. in mm | |||||||||

| Ply Number | ||||||||||

| Belt Type | Fabric Code | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Nylon Conveyor Belt | NN100 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 |

| NN125 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 | |

| NN150 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 | |

| NN200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 | 1400 | |

| NN250 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 | 1400 | |

| NN300 | 400 | 500 | 630 | 800 | 1000 | 1250 | 1400 | 1400 | 1600 | |

| NN400 | 500 | 630 | 800 | 1000 | 1250 | 1400 | 1600 | 1600 | 1800 | |

| NN500 | 630 | 800 | 1000 | 1250 | 1400 | 1600 | 1600 | 1800 | ||

| NN600 | 800 | 1000 | 1250 | 1400 | 1600 | 1600 | 1800 | 2000 | ||

| EP Conveyor Belt | EP100 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | ||

| EP125 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | |||

| EP160 | 250 | 400 | 500 | 630 | 800 | 1000 | 1250 | |||

| EP200 | 315 | 500 | 630 | 800 | 1000 | 1250 | 1400 | |||

| EP250 | 400 | 630 | 800 | 1000 | 1250 | 1400 | 1600 | |||

| EP300 | 500 | 630 | 800 | 1000 | 1250 | 1400 | 1600 | |||

| EP400 | 630 | 800 | 1000 | 1250 | 1400 | 1600 | 1800 | |||

| EP500 | 800 | 1000 | 1250 | 1400 | 1600 | |||||

| EP600 | 800 | 1000 | 1250 | 1400 | 1600 | |||||

Certifications

Packaging & Shipping

Hot Searches