NaN / 0

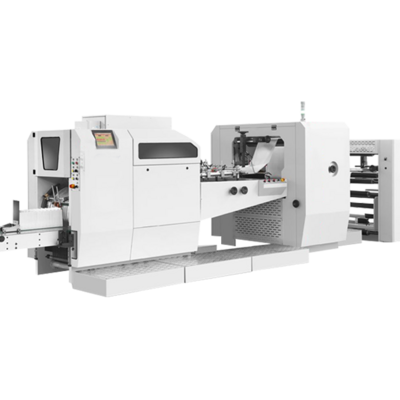

HD-330 Roll Fed Square Bottom low cost paper bag making machine

Get Latest Price

US$ 70000

≥1 Sets

Quick Details

Production Capacity:

45 days

Place of Origin:

Jiangsu, China

Brand Name:

NANJIANG

Voltage:

380V

Product Details

HD- 33 0 Semi Automatic Roll Fed Square Bottom Paper Bag Making Machine

Performance And Characteristics:

This machine features a continuous function of automatic paper suction gluing, creasing, bottom sticking and bag formation at a stroke. The machine has automatic force controlling machine and the function of color marking tracking. All the operation procedures are controlled by PLC, saving labor force. This is ideal equipment for making paper bag for shopping, Bakery, loading foods and so on.

Sample Bags:

Main Technical Parameter

|

Speed (bag/min.) |

80-190 |

|

Total Power (kw) |

10 |

|

Machine Weight (Ton) |

10 |

|

Machine Dimension (L*W*H) |

12000*2000*2100mm |

|

Paper Roll Width (mm) |

490-990 |

|

Maximum Paper Roll Width (mm) |

1000 |

|

Paper Gram Weight (gsm) |

60-150 |

|

Bag tube length (mm) |

330-650 |

|

Bag Width (mm) |

120-330 |

|

Bag Bottom Width (mm) |

60-150 |

Packaging & Shipping

Our Services

Services Terms:

A. Installation and training are done by our technician(s) at buyer’s factory.

Buyer should send an invitation letter for visa application.

The return flight tickets, accommodation & traffic expenses and service fees at USD100/day/person shall be borne by the buyer.

B. Seller provides 2 years Guarantee period, all spare parts free of charge in one year time.

C. After sale services and component replacement

During the period of quality guarantee, we supply the spare part in free for replacement.

D. Packaging

Adopts moisture-proof and shock-proof packaging which is suitable for long-distance road transportation and various types of weather conditions. A full set of maintenance and operation manuals is included.

E. Delivery time

Within 90 days after receive 30% advance payment.

F. Payment terms

30% by T/T as advanced payment, 70% by T/T or irrevocable L/C at sight before shipment(After inspection).

Hot Searches