NaN / 0

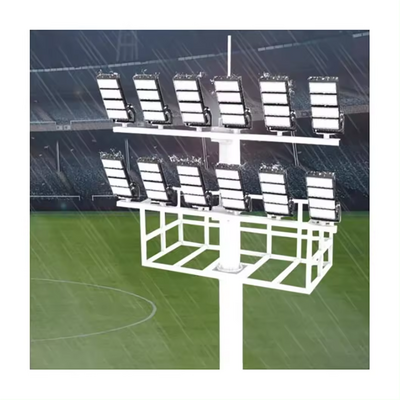

Q235 3m-35m High Mast Pole Foundation Design / Galvanized Pole Manufacturers/ Street Light Poles

Get Latest Price

US$ 1000

≥1 Sets

Quick Details

Material:

Steel

Type:

Polygonal

Application:

Square

Place of Origin:

Jiangsu, China

Product Details

Product Description

| Product Name |

High Mast Poles From 20m To 40m With Hot Dip Galvanization And/Or Powder Coating |

Application |

• Street/Roadway lighting

|

|||||

| Material |

Q235B (SS400)

S355 Q345B(ASTM A572 Gr.50) |

Shape |

» Conical

» Octagonal » Tapered round |

|||||

| Thickness | 4mm-30mm |

Installation Method |

Frange Connection

/ Direct Buried |

|||||

| Surface Treatment |

Hot Dip Galvanization/ Powder Coating |

H.D.G. Standard |

GB/T 13912-2002

or ASTM A 123 |

|||||

| Welding Standard |

GBT 12467.2-2009

/ AWS D 1.1 / BS EN 1011-1 |

Install Method

Of The Pole |

Slip Joint /Base Plate |

|||||

| Package |

Nude Packing or Customized |

Service Life Of The Poles |

More than 30 Years | |||||

With more than ten years experiences on the steel pole,we have manufactured and exported huge quantity of hot dip galvanized and /or high mast Poles from 20m to 40m which service for the lighting industry development of the world.We have the complete production line and machines,and skillful workers with high efficiency which can make us produce 10 tons or 5 sets of the electric power poles everyday. A quick production period and delivery schedule ensured our client have more obvious advantage in their market.

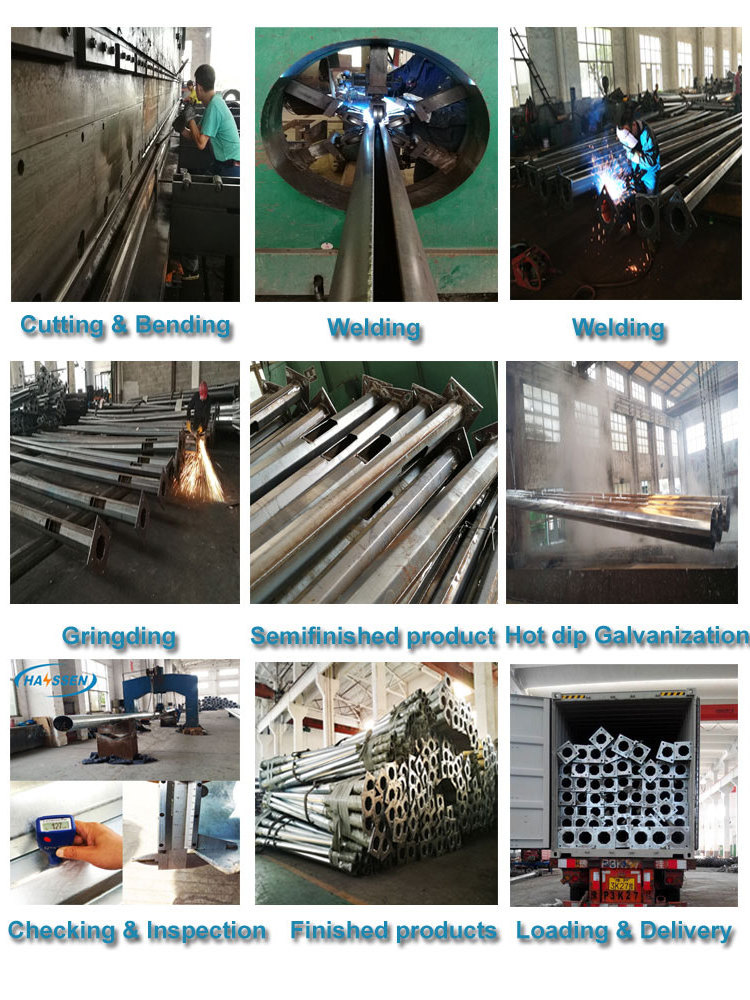

The high mast Pole is made by the high-quality hot rolled steel plate which was bent into Trapezoid according to the poles's dimension,then welding ,grinding,hot dip galvanized and packing for delivery as following shows:

Key information of the steel poles:

>> Material:we just only choose qualified & famous steel manufacturer's products such as Bao Steel,Shagang Steel,Shougang Steel ect to make sure our product's quality. Any material was found the defects,then all the rest materials which purchased together with it will be refused and forbidden to be receipt by the warehouse.

>> Welding: we welding the high mast poles with gas shielded welding and submerge-arc welding with perfect welding line and good quality,we strickly control the test the welding by the flaw testing with ultrasonic crack detection to make sure there is no crack,undercut,slag inclusion,hole vent for the welding.

>> Hot dip galvanization: all our products must be hot dip galvanized according to GB/T13912-2002 or ASTM A123 which can keep the steel poles without rust more than 30 years.Our standard for a good hot dip galvanization steel pole is same color of the zinc coating without dent mark,no exposed iron and hang of zinc of defect. Normally speaking,the thickness of the zinc coating is up to the materials thickness.The thicker the material is, the thicker the zinc coating will be.

Packaging & Shipping

Because of there is nearly no any accessories on the poles shaft,so most of the clients agree with delivery the 25ft -40ft steel poles without package which is can save the space of the container,and also can save the purchasing cost.

Of cause,if our clients have request or standard for the package of the steel poles,we are also glad to packing the steel poles according to client's request.

Our Services

We always insist on one-on-one service to our client since our first contact with our clinet to save our client's time and no need to spend their time to rebuild the trust and relationship with new service personal.

Because of the time difference between us and our client, we do our best to provide 7*24 service to let our clients can contact with us as solve their questions ASAP. The minimum standard we promise you that all your questions can be received our reply within 12 hours.

Hot Searches