NaN / 0

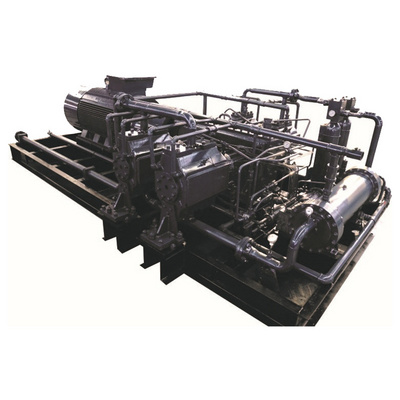

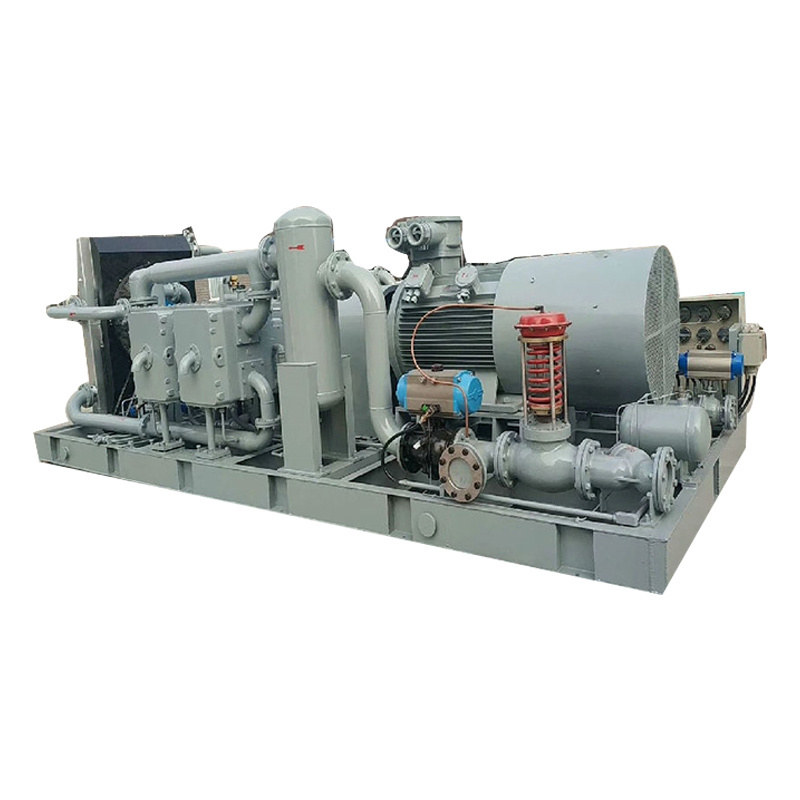

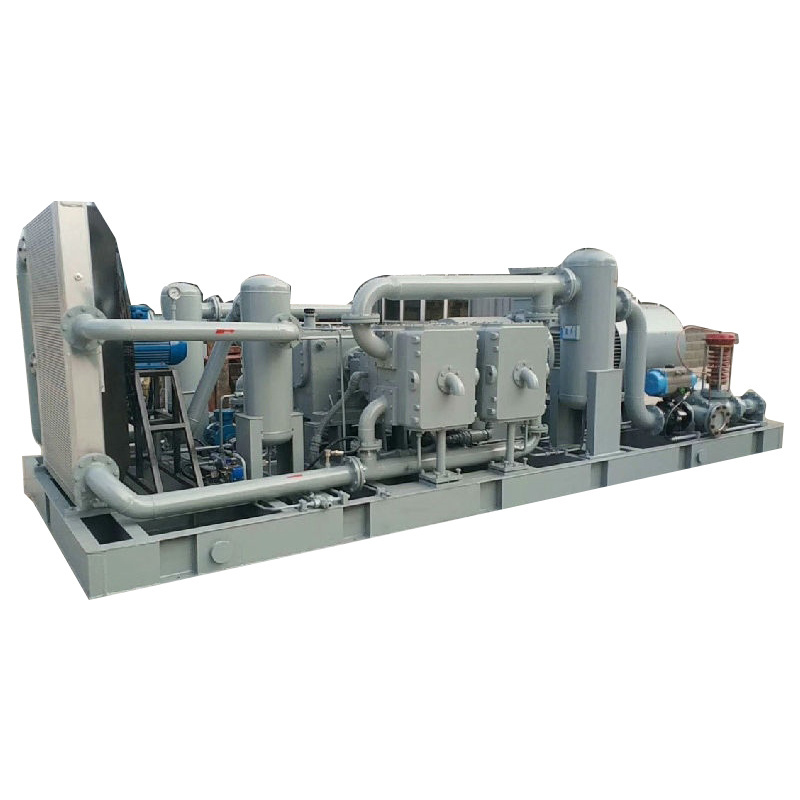

Industrial High Pressure CNG Natural Gas Piston Air Compressor for Gas Filling Station

Get Latest Price

US$ 28000

≥1 Sets

Quick Details

Place of Origin:

Shanghai, China

Brand Name:

Rocky

Voltage:

300-10000V

Dimension(L*W*H):

7000x2700x2200mm

Product Details

Product Description

Industrial High Pressure CNG Natural Gas Piston Air Compressor for Gas Filling Station

Large compressor types are divided into: symmetrical balance type, M type.

The middle body between the slideway and the cylinder can be designed with a long-shaped single-chamber, a short-shaped single-chamber, an extended-shaped double-chamber, and a long-short dual-chamber structure according to user requirements; it adopts a water-cooling system, and all levels are equipped with intake and exhaust buffers There are two sets of lubricating systems. When the oil pressure is low, the auxiliary oil pump system automatically starts to run. All equipment is integrated on the skid-mounted base, which has the characteristics of compact structure, good sealing performance, small starting torque, good inertia force balance, small mechanical vibration, high reliability, easy maintenance, and long service life.

Lubrication method: 1. Without oil 2. With oil

Cooling method: 1. Water cooling 2. Air cooling 3. Mixed cooling (selected according to actual needs)

Overall structure: fixed, mobile, skid-mounted, soundproof cabin, etc. (selected according to actual needs)

In addition to the functions of a standard station, the CNG refueling mother station also fills compressed natural gas into a high-pressure gas transport semi-trailer (referred to as a semi-trailer) through the refueling column located in the station, and transports it to the refueling sub-station to refuel the vehicle. At the same time, as an effective supplement to pipeline gas transmission, in small and medium-sized cities far away from natural gas pipelines, semi-trailers can be used to transport compressed natural gas by road to the cities where it is used. Other natural gas users supply gas.

| 1 | Compressor type | M A -5.33/5.5-60 | |||

| 2 | Structure | M-type, horizontal symmetrical balance | |||

| 3 | Rotating speed | 988rpm | |||

| 4 | Compression stage | 3 | |||

| 5 | Medium | Natural gas | |||

| 6 | Final discharge pressure | 60bar | |||

| 7 | Inlet pressure bar | 5.5 | |||

| 8 | Discharge capacity Nm3/h | 5900 | |||

| 9 | Shaft power KW | 550 | |||

| 10 | Discharge temperature | 15 ºC not higher than the environmental temperature | |||

| 11 | Main motor | Power | Voltage | Explosion -proof grade | Protection grade |

| 600KW | 380V | ExdIIBT4 | IP55 | ||

| 12 | Reverse angle | 156 degree | |||

| 13 | Peak-to-valley ratio of piston force | 44 % | |||

| 14 | Cooling type | Gas: air cooling , cylinder: non-cooling | |||

| 15 | Drive type | direct-connected drive through diaphragm coupling( no flywheel ) | |||

| 16 | Lubrication type | Oil-less | |||

| 17 | Installation mode | Skid mounted | |||

| 18 | Control type | PLC + touch screen + soft-start | |||

| 19 | Dimensions(LxWxH) | 7000x2700x2200mm | |||

| 20 | Weight | 18000kg(about) | |||

Gas Compression Products

Rocky is committed to delivering integrated compression solutions tailored to our customers' specific requirements. We offer all series of compressors with electric motor or gas engine to ensure safe and reliable operation.

Rocky's packaged units can be used both onshore and offshore with a range from 85 HP to 10,000 HP.

Extensive application experience from oil and gas fields to chemical plants gives Rocky a deep understanding of customer needs as well as industry standards in different countries and regions. In addition, we can also provide engineering services for gas collection station, gas supply and underground gas storage facilities, etc.

Ambient temperature: -140 F - 122 F (-60 C - +50 C)

Pressure range: 0 - 8990 psi (0 - 61.98 MPa)

Power range: 10 HP - 10000 hp (7.46 - 7457 kW)

Process gas: natural gas, air, hydrogen, ethane, nitrogen, propane, CO2, BOG, etc.

Mounting types: automotive, stationary, mobile and pile mounting

Application: injection, collection, utilization of associated gas, injection of fuel gas, CNG, etc.

Packaging & Shipping

• Packing Details: Plywood crate pallet plus foam board and bubble film, Full closed wooden case. 1pcs/each package (for stationary screw air compressor)

• Shipping method: by sea, by LCL/FCL or as requested

• Delivery method: FOB, CFR, CIF and EXW etc.

• Delivery time: in 7-15 days after receiving deposit (customized machines not included)

Hot Searches