NaN / 0

QUANYI Brand Lasting Line Shoe Toe part Flattening Machine For Shoe Making

Get Latest Price

US$ 3325

≥1 Sets

US$ 3100

≥10 Sets

Quick Details

Weight (KG):

310

Marketing Type:

Hot Product 2024

Place of Origin:

Guangdong, China

Brand Name:

QUANYI

Product Details

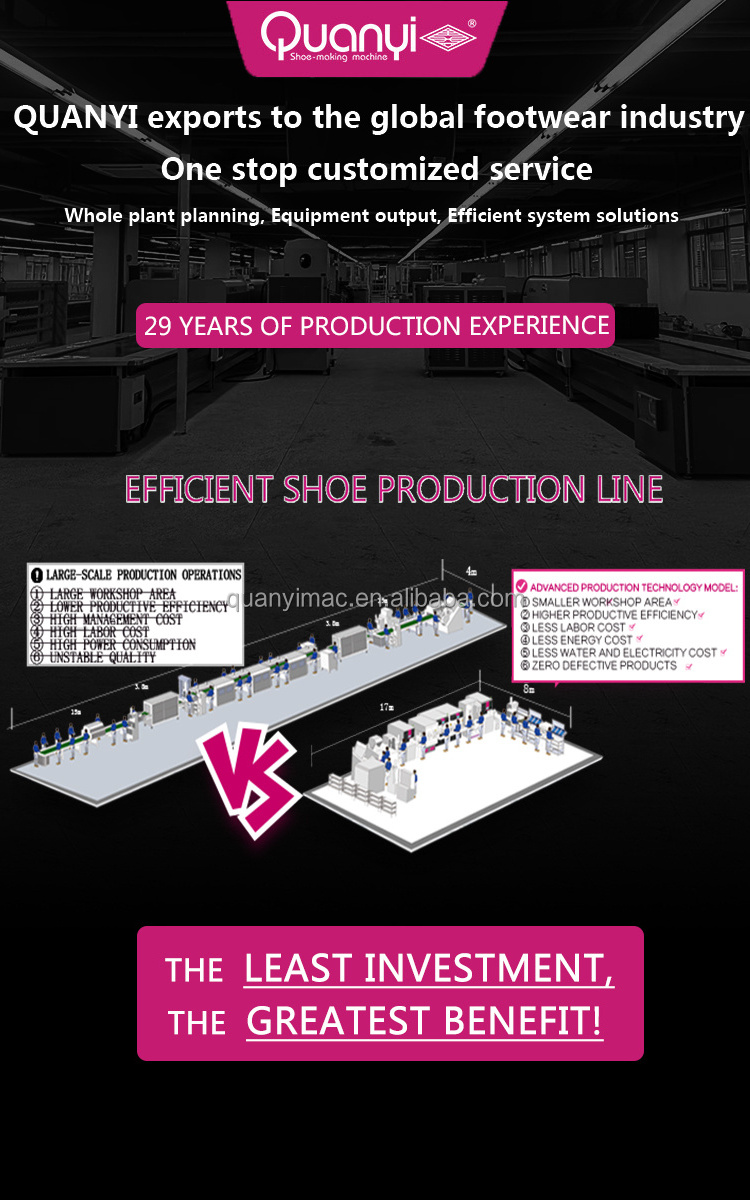

About QUANYI

|

|

One traditional production line

(production capacity of 1600 pairs)

|

Two lean production lines (production capacity of 800pairs/piece)

|

|

||

|

Number of workers (including management)

|

55+3

|

18+2

|

|

||

|

Per capita efficiency

|

3 Pair

|

4.1 Pair

|

↑37%

|

||

|

Cost of worker wages

|

1820000

|

1188000

|

632000

|

||

|

Manage salary costs

|

165000

|

11000

|

55000

|

||

|

Rent cost

|

228 square meters/55000

|

136 square meters/32000

|

23000

|

||

|

Water and electricity costs

|

306600

|

102200

|

204400

|

||

|

Tool cost

|

300 pairs/525000

|

50 pairs * 2 pieces/260000

|

265000

|

||

|

Last turnover period

|

120-180 minutes

|

60-80 minutes

|

60-100 minutes

|

||

|

Directly reduce costs

|

|

|

11800

|

||

|

Product model

|

|

QY806A

|

|

||

|

Product name

|

|

Toe seat Flattening Machine

|

|

||

|

Voltage

|

|

380V

|

|

||

|

Power

|

|

0.7KW

|

|

||

|

Function

|

|

Shoe Boarder Pounding And Flattening Process After Lasting

|

|

||

|

Machine Dimensions

|

|

700*930*1600MM

|

|

||

|

Type

|

|

SEMI AUTOMATIC

|

|

||

|

N.W/G.W

|

|

400KG

|

|

||

|

Warranty

|

|

1 YEAR

|

|

||

Purpose:

Feature:

2. By means of the ironing effect of heating-plate and the beating effect of vibrating-roller, The surface of heel-seat will be

flat and have a better edge.

3. Rotation speed of last and travel speed of vibrating-roller are adjustable as required.

4. The beating frequency of vibrating-roller can be adjusted.

SPECIFICATION

DIMENSION:700*930*1600MM

N.W.:400KG

VOLTAGE:380V

POWER:0.7KW

CAPACITY:2500PAIRS/8H

N.W.:400KG

VOLTAGE:380V

POWER:0.7KW

CAPACITY:2500PAIRS/8H

FAQ

Hot Searches