Sign a confidentiality agreement for customer information, keep confidential samples separately, do not display them in the sample room, and do not send pictures to other customers or publish them on the Internet.

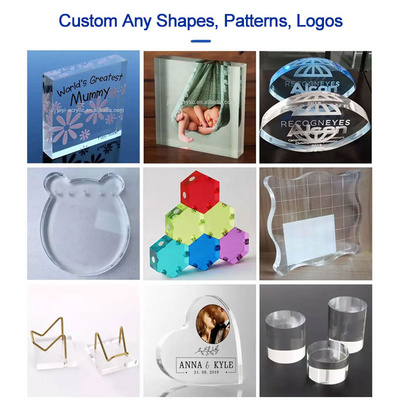

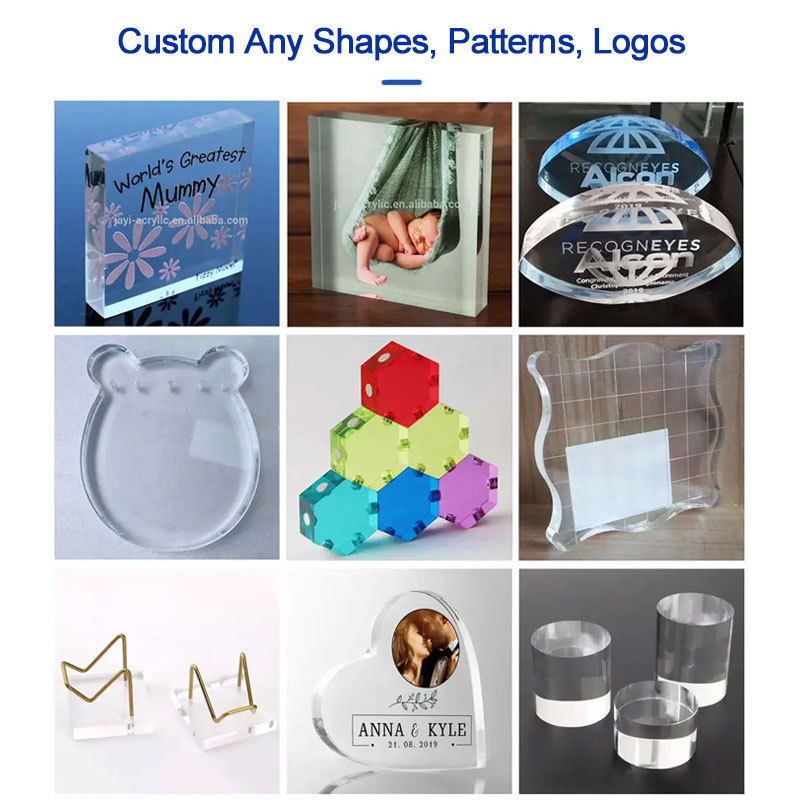

Advantages and disadvantages of our company in the acrylic manufacturing industry?

Advantage:

1. The source manufacturer, only acrylic products in 19 years

2. More than 400 new products are launched a year

3. More than 80 sets of equipment, advanced and complete, all processes are completed by themselves

4. Free design drawings

5. Support third-party audit

6. 100% after-sale repair and replacement

7. More than 15 years of technical workers in acrylic proofing production

8. With 6,000 square meters of self-built workshops, the scale is large

Shortcoming:

Our factory specializes in only acrylic products, other accessories need to be purchased.

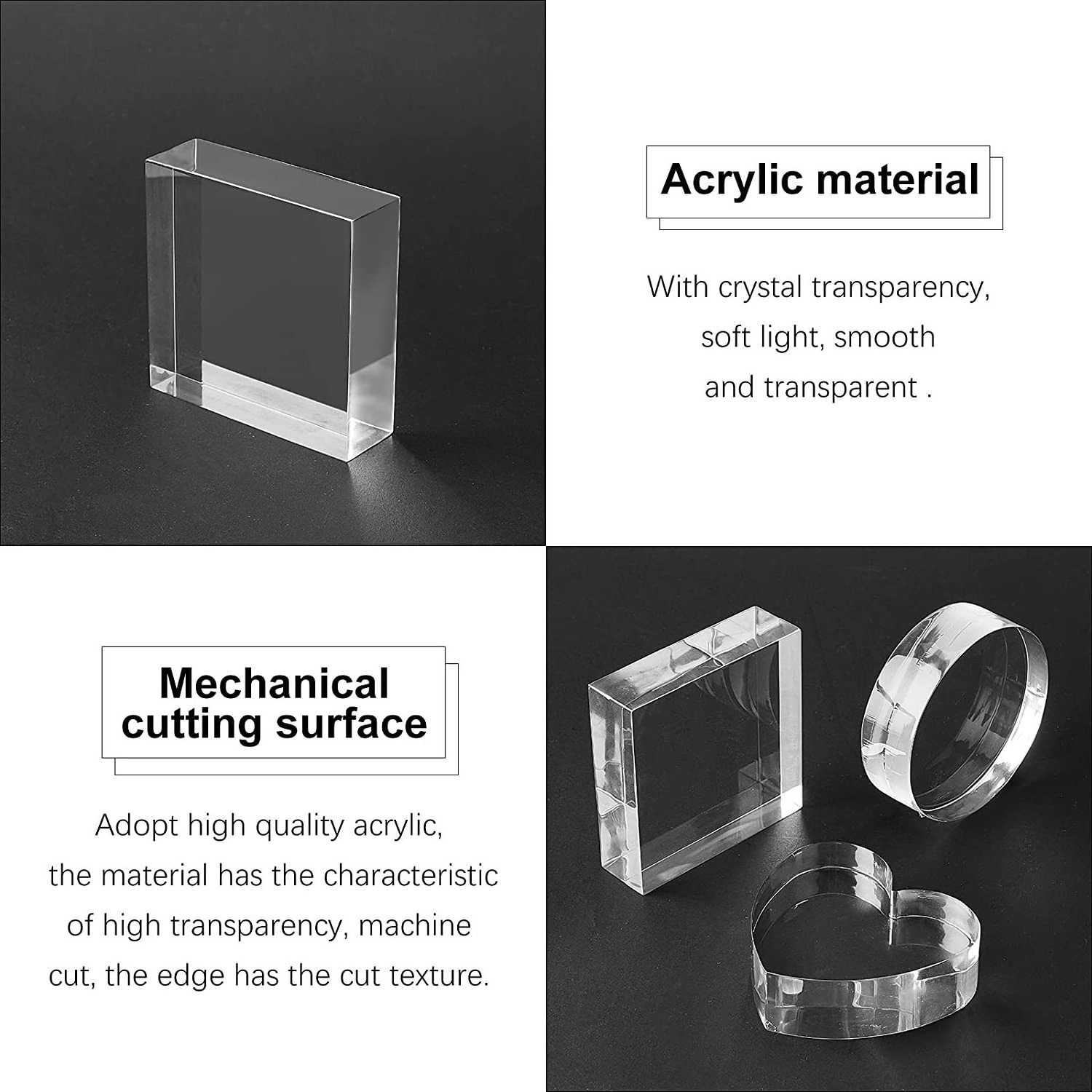

What are the safety features of the acrylic products produced by our company?

Safe and not scratching hands; material is safe, non-toxic and tasteless; no burrs, no sharp corners; not easy to break.

How long does it take for acrylic products to be delivered?

3-7 days for samples, 20-35 days for bulk

Do acrylic products have MOQ? If yes, what is the minimum order quantity?

Yes, minimum 100 pieces

What is the quality process for our acrylic products?

Raw material quality inspection; production quality inspection (pre-production confirmation of samples, random inspection of each process during production, and re-inspection of the whole when the finished product is packaged), 100% full inspection of the product.

What are the quality problems that have occurred in acrylic products before? How is it improved?

Problem 1:

There are loose screws in the cosmetic storage box

Solution:

Each subsequent screw is fixed with a little electronic glue to prevent it from loosening again.

Problem 2:

The grooved part at the bottom of the album will scratch your hands slightly.

Solution:

Follow-up treatment with fire throwing technology to make it smooth and not scratch your hands.

Are our products traceable? If so, how is it implemented?

1. Each product has drawings and production orders

2. According to the product batch, find various report forms for quality inspection

3. Each batch of products will produce one more sample and keep it as a sample

What is the yield of our acrylic products? How is it achieved?

One: Quality Target

1. The qualified rate of one-time product inspection is 98%

2. Customer satisfaction rate above 95%

3. Customer complaint handling rate is 100%

Two: Quality Management Program

1. Daily IQC feed report

2. The first product inspection and confirmation

3. Inspection of machinery and equipment

4. Sampling AQC Checklist

5. Production process quality record sheet

6. Finished product packaging inspection form

7. Unqualified record form (correction, improvement)

8. Customer complaint form (improvement, improvement)

9. Monthly production quality summary table