NaN / 0

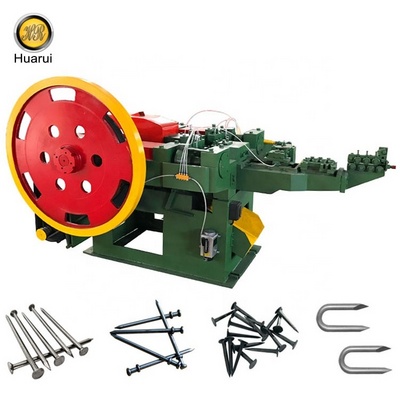

3-6 inch common/ roofing /iron steel screw concrete small nail making machines Z94-1C Z94-2C Z94-3C Z94-4C Z94-5C

Get Latest Price

US$ 2500

≥1 Pieces

US$ 2400

≥5 Pieces

Quick Details

Production Capacity:

450pc/min

Place of Origin:

Henan, China

Brand Name:

YW

Power (kW):

1.5KW

Product Details

3-6 inch common/ roofing /iron steel screw concrete small nail making machines Z94-1C Z94-2C Z94-3C Z94-4C Z94-5C

The main parts of this n ail making machine (shaft, cam, gear) are made of high-grade steel with professional heat treatment, so as to ensure longer working life and less time maintenance. Each model machine could make different kinds of size nail, the nail length can be adjusted on the machine and different nail diameter needs related diameter coil wire. Each Automatic wire nail making machine adopts related nail clamping die, nail knife and punch pin and spare parts.

Detailed Images

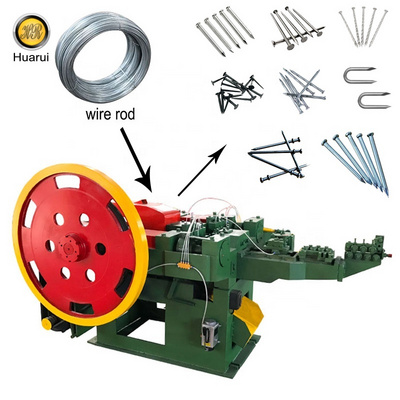

Working principle:

The machine has only one piece punch bar, one pair nail die, and one pair nail cutter, the machine nail die will grip the steel wire and the punch bar will punch to get the nail head, and the nail cutter to cut the nail point. this structure decides that it can make only one nail per time.

This type nail-making machine adopts a plunger structure, driven by 3 phase electric motor and is equipped with auto oil pipe lubrication.

Wire Nail Making Process:

1. Wire Straightening: put the wire coil on pay-off rack and input wire to traightening device for straightening.

2. Wire Feeding: The feeding box will grip and feed the steel wire continuously.

3. Nail head Forming : When the steel wire is clamped by the gripping mechanism, the punch system will punch the wire to form the nail head.

4. Nail Tip Cutting : After the extrusion is completed, the cutting mechanism cuts the wire, and an emergency return mechanism can be used.

5. Final Step: The gripping die open, the nail is dropped down and the next nail will be made continuously.

Related Products

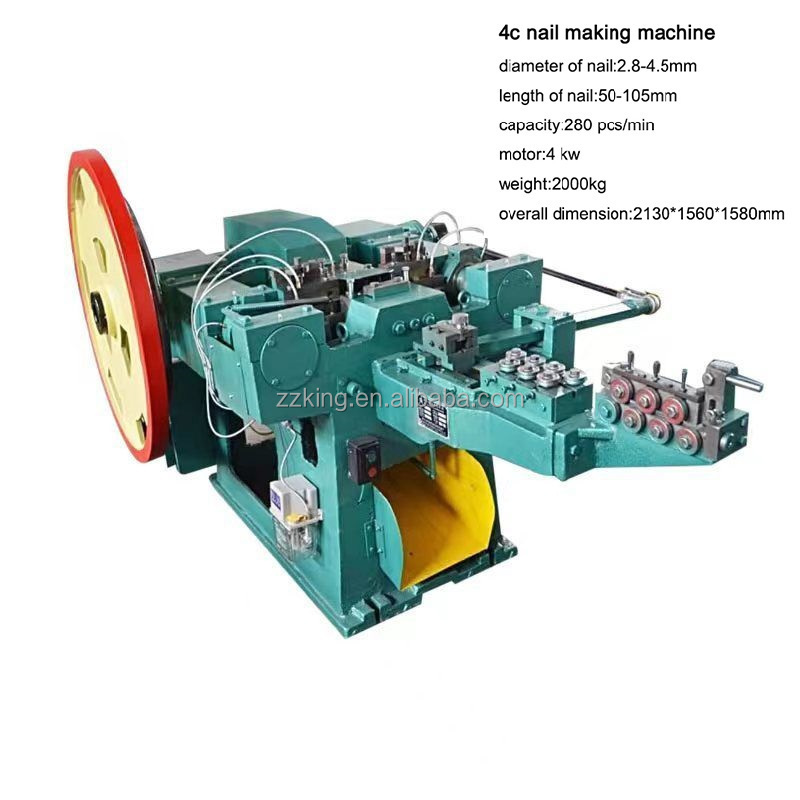

Specification:

|

Common Type Nail Making Machine |

|||||||

|

P/N |

Nail Length (mm) |

Nail Dia. (mm) |

Capacity (pcs/min) |

Weight (kg) |

Power (kw) |

Dimension (mm) |

|

|

Z94-1C |

9.0-25 |

0.9-1.6 |

450 |

450 |

1.5 |

1440*1040*1270 |

|

|

Z94-2C |

16--50 |

1.2-2.8 |

350 |

760 |

3.0 |

1700*1300*1400 |

|

|

Z94-3C |

40-80 |

2.0-3.4 |

280 |

1050 |

3.0 |

2000*1400*1400 |

|

|

Z94-4C |

70-110 |

3.4-5.0 |

220 |

2000 |

4.0 |

2400*1600*1650 |

|

|

Z94-5C |

70-180 |

3.4-5.0 |

200 |

2200 |

5.5 |

2600*1600*1650 |

|

|

Z94-6C |

70-220 |

3.4-8.0 |

160 |

4400 |

7.5 |

3300*1650*1750 |

|

|

Z94-8C |

100-330 |

3.0-8.0 |

60-90 |

5600 |

11.0 |

3500*1850*1900 |

|

Product Overviews

Packaging & Shipping

Certifications

Buyer Feedback

Our Services

Hot Searches