NaN / 0

stainless steel tomato sauce colloid mill making machine sachet packing machine apple sauce grinder

Get Latest Price

US$ 999

≥1 Sets

Quick Details

Brand Name:

Fusion

Place of Origin:

Henan, China

Voltage:

customized

Power:

3 phases

Product Details

stainless steel tomato sauce colloid mill making machine sachet packing machine apple sauce grinder / factory directly supply other food processing machine colloid mill/peanut butter machine

Product Description

1. Brief introduction of the peanut butter product line :

Main equipments of this line are : Peanut roaster, belt conveyor, Peanut debarking and separating ,Peanut butter grinding , Mixing tank and vacuum tank, Filling machine.

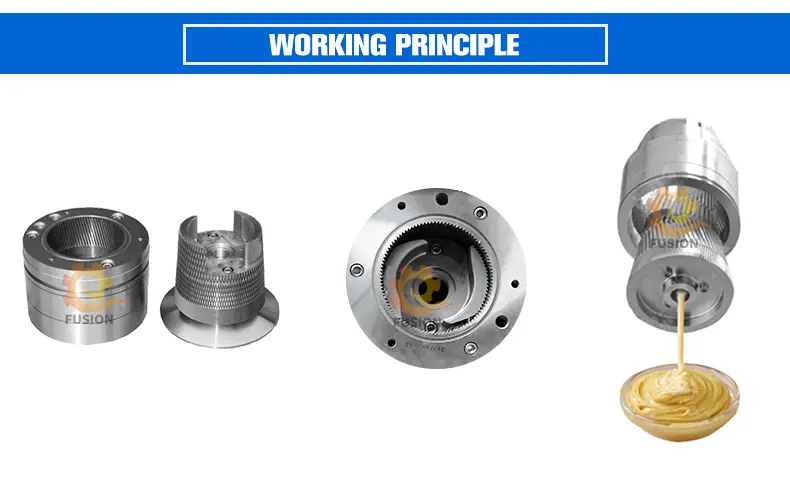

Colloidal grinding products are machines that process fine materials in fluids. He integrates the multi-functional performance of homogenizer, ball mill, three-kun machine, shearer, mixer and other machinery, and has the functions of ultra-fine crushing, dispersing emulsification, homogenization and mixing.

After the material is processed, the particle size is 2-50 microns, and the homogeneity is more than 90%. It is the ideal equipment for ultra-fine particle processing

Technical parameters for the peanut butter product line:

You can choose the Full Peanut butter machine product line capacity according to your requirements such as 100-200kg/h,200-300kg/h.

Also you can refer to the capacity of the peanut butter :

| Model | Fineness(mesh) | Capacity(kg/h) | Power (kw) | Weight (kg) | Size(mm) |

| FX-50 | 50-100 | 10-15 | 1.5 | 50 | 530*260*580 |

| FX-80 | 50-100 | 30-70 | 4 | 150 | 640*410*900 |

| FX-110 | 100-200 | 150-200 | 7.5 | 175 | 700*430*980 |

| FX-130 | 100-200 | 300-500 | 11 | 285 | 830*440*1100 |

| FX-180 | 100-200 | 600-800 | 18.5 | 340 | 830*490*1100 |

| FX-240 | 100-200 | 1000-2000 | 45 | 1300 | 1320*600*1280 |

| FX-300 | 60-200 | 3000-4000 | 75 | 1600 | 1500*800*1120 |

Optional colloid mill:

Vertical or horizontal design; feeding: pump, hopper or screw feeder; multiple fineness stator and rotor' grinding interval adjustment; double-layer mechanical seal; with external cold water port or pressure type sealing liquid interface; grinding bin belt Double-layer jacket; fixed and movable;

Vertical or horizontal design; feeding: pump, hopper or screw feeder; multiple fineness stator and rotor' grinding interval adjustment; double-layer mechanical seal; with external cold water port or pressure type sealing liquid interface; grinding bin belt Double-layer jacket; fixed and movable;

Machine material: 2Cr13, SUS304, SUS316, two-way stainless steel and other customized requirements

3. Scope of application for the peanut butter product line:

The machine is suitable for ultra-fine crushing of micro-wet materials in pharmaceutical, food, chemical and other industries, and can be used to crush, emulsify, homogenize and mix various semi-wet bodies and emulsion materials.

(1) Various nuts: such as peanuts, sesame, almonds, cocoa beans, macadamia, etc.

(2) Various cereals: corn, soybeans, red beans, etc.

(3) Vegetables and fruits: tomatoes, apples, peppers, potatoes, onions, potatoes , meat etc.

2/Peanut debarking and separating

the function is to peel and dice raw peanuts. The parameters are Capacity:200-600kg/h

Power of Motor:1.29kw

Wholekernelrate:70%

Size:1100*700*1000mm

Rollers:8

Power of Motor:1.29kw

Wholekernelrate:70%

Size:1100*700*1000mm

Rollers:8

3/Peanut butter grinder

The function is to put the peanut into the hopper with the elevator,the grind the peanut into the sauce with the parameters

Mixing tank and vacuum tank

The main purpose of the mixing tank is to stir,mix,blend and homogenize the peanut butter.

Filling filling machine

The function is to fill peanut butter into kinds of bottles.

Packaging & Shipping

1. Packing: PP film wrapped around the machine and carefully packed in wooden case to focus on protecting damageable parts.

2. Shipping: From port of Shenzhen, Shanghai, Qingdao, Guangzhou,etc. We also accept land, air, sea transport and internationalmultimodal transport.

3. Clearance: Our long history makes us the one of the first and most knowledgeable providers of the equipment, our main customers

hail from; Canada, the United States, Brazil, Argentina, Japan, Philippines, Australia, Russia, Thailand, the UAE, Poland, Spain,Germany, India, etc.

Our Services

1. We always welcome customers to visit our manufacturing factory and get to know more about us.

2. Customers can see all the manufacturing workflows when they visit our factory. you can contact with online besides offline:

Wechat / WhatsAPP / iMessages: 008615503747612

3. We also send engineers to the customer's place to help with the installation!

Hot Searches