NaN / 0

Lianggong Plastic Formwork Wall Slab Column Formwok for Building Concrete Mold PVC Formwork for Concrete Structure Croatia

Get Latest Price

US$ 52.5

≥100 Square meters

US$ 51.26

≥500 Square meters

Quick Details

Warranty:

1 Year

After-sale Service:

Online technical support, Onsite Installation, Onsite Training, Onsite Inspection

Project Solution Capability:

graphic design, 3D model design, total solution for projects

Application:

Hotel

Product Details

Product Description

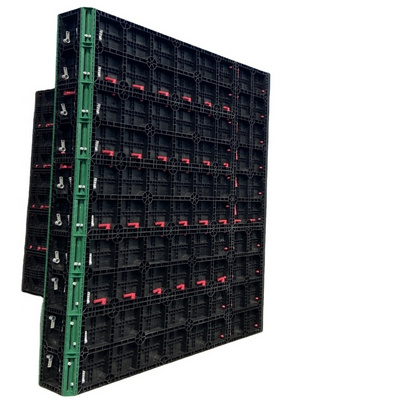

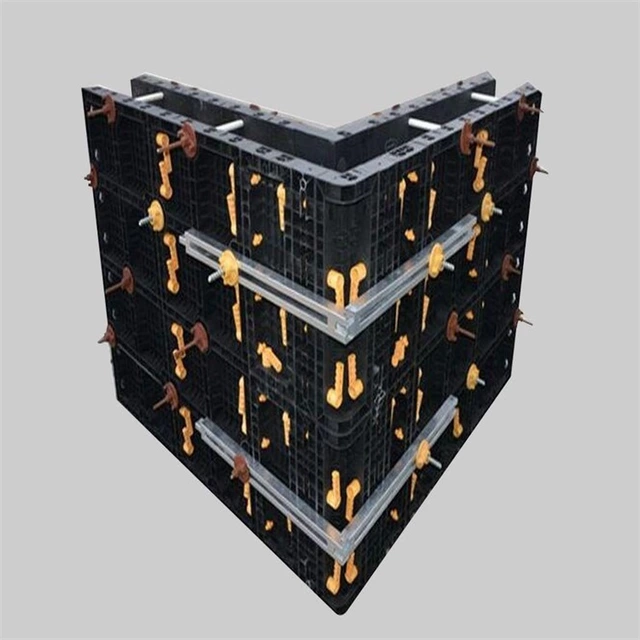

Plastic formwork

In particular,the plastic formworks offered by

LIANGGONG

are suitable for concrete columns,pillars,walls,and foundations directly onsite.Their modularity allows to satisfy every construction and planning needs;columns and pillars of different shapes and dimensions,walls and foundations of different thickness and height.

Products Show

Characteristics

|

1.Long lifespan& Cost effective -- Plastic formwork can be reused over 100 times,while plywood can only be reused 3 to 5times.Therefore the plastic formwork is more cost effective.

|

|

|

|

|

||||

|

2.Waterproof -- As the nature of plastic material. It's imputrescible and rustless,especially suitable for underground and watery circumstance.

|

|

|

|

|

||||

|

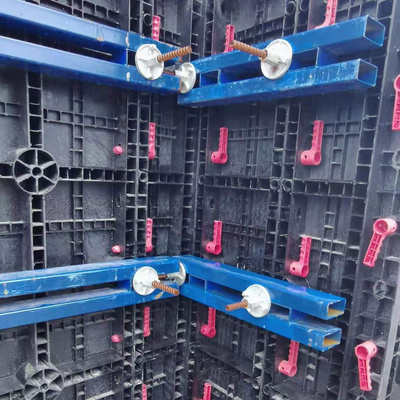

3.Interlocking Design -- No release agent needed, good effect of demolding.

|

|

|

|

|

||||

|

4.Easy deassembly -- The template will be separated easily from concrete.

|

|

|

|

|

||||

|

5.Simple Installation -- Light weight and safe to handle, easy cleaning and very robust.

|

|

|

|

|

||||

|

6.High Quality -- Abrasion resistance, excellent mechanical property, best impermeability.

|

|

|

|

|

||||

|

7.Recycable -- Waste scrap molding board could be recycled.

|

|

|

|

|

||||

Packing & Delivery

Packing:

1.Generally, the total net weight of loaded container is 22 tons to 25tons, which need be confirmed before loading.

2.Different packages are used for different products:

---Bundles:Timber beam, steel props, tie rod, etc.

---Pallet:Small parts will be put in bags and then on pallets.

---Wooden cases:It is available on customer's request.

---Bulk:Some irregular goods will be loaded in bulk in container.

Delivery:

1.Production: For full container, normally we need 20-30 days after receive customer's down payment.

2.Transportation: It depends on the destination charge port.

3.Negotiation is needed for special requirements.

Our Service

1.Consulting,Design,and Quotation

Offer you a general idea of formwork & scaffold among LiangGong various systems, to fit your project demand.

Design and Customized forming & shoring proposal according to your structural drawing by Auto-CAD.

2.Manufacture and Quality Inspection

Large-scale production workshop and First-class production line, as well as a professional quality inspection team, which will

provide you with high quality standard products.

Test report will be available according to different norms from different regions in order to offer no worries to clients or meet

destination authority requirements.

3.Packing and Shipment

From fabrication to loading, use standard export packages to get to your site quickly.

4.Remote or On-site instruction

If you have any questions, we can provide remote or on-site guidance. Our aim is to make customers feel at ease and satisfied

throughout the process.

Offer you a general idea of formwork & scaffold among LiangGong various systems, to fit your project demand.

Design and Customized forming & shoring proposal according to your structural drawing by Auto-CAD.

2.Manufacture and Quality Inspection

Large-scale production workshop and First-class production line, as well as a professional quality inspection team, which will

provide you with high quality standard products.

Test report will be available according to different norms from different regions in order to offer no worries to clients or meet

destination authority requirements.

3.Packing and Shipment

From fabrication to loading, use standard export packages to get to your site quickly.

4.Remote or On-site instruction

If you have any questions, we can provide remote or on-site guidance. Our aim is to make customers feel at ease and satisfied

throughout the process.

Our Company

Lianggong Formwork Co.,Ltd. is one of the leading formwork and scaffolding companies headquartered in Nanjing City, China, with

its factories located in Jianhu Economic Development Zone of Yancheng City, Jiangsu Province. As a well-established company in

construction formwork field, Lianggong has been devoted itself and specialized in formwork and scaffolding research, development,manufacturing, and labor service.

During the years of hardworking since 2010 by the whole company staff, Lianggong has successfully delivered and served a large

number of projects at home and abroad, such as bridges, tunnels, power stations, and industrial & civil constructions. Major

products of Lianggong include H20 timber beam, wall and column formwork, single-sided bracket, crane-lifted climbing formwork,

hydraulic auto-climbing system, protection screen and unloading platform, shaft beam, table formwork, ring-lock scaffolding and

stair tower, cantilever forming traveller and hydraulic tunnel lining trolley, etc.

Utilizing its strong technical background and abundant engineering experience, and always bearing in mind to keep its

cost-effectiveness and efficiency for clients, Lianggong will continue to be your best partner in any project from the very start

and achieve higher and further goals together.

its factories located in Jianhu Economic Development Zone of Yancheng City, Jiangsu Province. As a well-established company in

construction formwork field, Lianggong has been devoted itself and specialized in formwork and scaffolding research, development,manufacturing, and labor service.

During the years of hardworking since 2010 by the whole company staff, Lianggong has successfully delivered and served a large

number of projects at home and abroad, such as bridges, tunnels, power stations, and industrial & civil constructions. Major

products of Lianggong include H20 timber beam, wall and column formwork, single-sided bracket, crane-lifted climbing formwork,

hydraulic auto-climbing system, protection screen and unloading platform, shaft beam, table formwork, ring-lock scaffolding and

stair tower, cantilever forming traveller and hydraulic tunnel lining trolley, etc.

Utilizing its strong technical background and abundant engineering experience, and always bearing in mind to keep its

cost-effectiveness and efficiency for clients, Lianggong will continue to be your best partner in any project from the very start

and achieve higher and further goals together.

Customer Photo

FAQ

Q1:Are you trading company or manufacturer?

Q3:What can you do for us?

Q5:What do you need in order to make a brief design and quotation when we have a construction project to be built? A:Structural drawing and section drawing.

Q6:How long does it take to make a brief design and quotation after we offer the structural drawing?

Q7:How long dose it take to manufacture the products after the signing of contract?

A:In general, it takes 30~60 days based on the type and quantity of products to be produced.

Q8:What is your terms of payment?

A:We are factory.

Q2:What do you do?

A:We design and manufacture formwork and scaffolding products used for pouring concrete structure in the field

of housing,multi-story structure, high rise buildings, towers, sports stadiums, bridges, hydropower stations, industrial structures etc.

of housing,multi-story structure, high rise buildings, towers, sports stadiums, bridges, hydropower stations, industrial structures etc.

Q3:What can you do for us?

A:We offer our suggestions, drawings of formwork layout, and quotations to the owners, design

institutes, or contractors of the construction projects.

institutes, or contractors of the construction projects.

B:We sell our products to the contractors, building companies, material

supplier or trading companies.

supplier or trading companies.

C:We support our worldwide peer companies with our outstanding formwork or scaffolding products.

D:We provide remote or on-site instruction to the builders.

D:We provide remote or on-site instruction to the builders.

Q4:Do you provide samples? is it free or extra?

A:Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q5:What do you need in order to make a brief design and quotation when we have a construction project to be built? A:Structural drawing and section drawing.

Q6:How long does it take to make a brief design and quotation after we offer the structural drawing?

A:In general, it takes 5~7 days based on specific requirements of construction project.

Q7:How long dose it take to manufacture the products after the signing of contract?

A:In general, it takes 30~60 days based on the type and quantity of products to be produced.

Q8:What is your terms of payment?

A:Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.