NaN / 0

Homogenizer Working Head Mixer 300l Cosmetic Cream Vacuum Homogenizing Emulsifier Mixing Machine

Get Latest Price

US$ 26850

≥1 Sets

US$ 23855

≥3 Sets

Quick Details

Barrel Volume (L):

500

Max. Loading Volume (L):

2000 L

Range of Spindle Speed(r.p.m):

0 - 65 r.p.m

Max. Loading Capacity:

3000l

Product Details

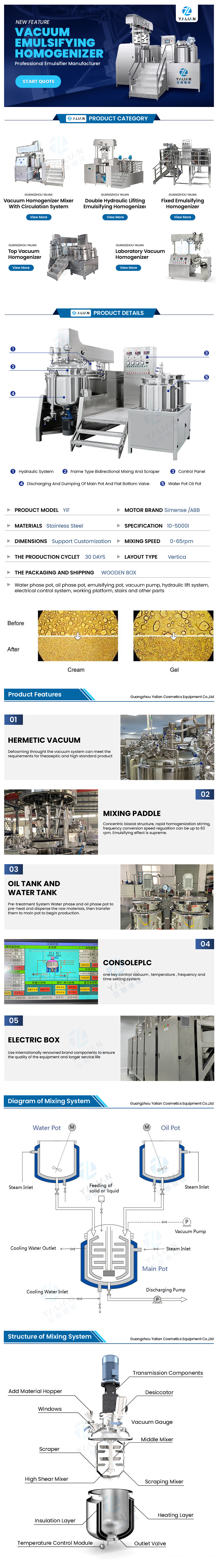

200L Tilting Vacuum Homogenizing Emulsifier (Cosmetic Production Equipment), Cream Homogenizing Machine

Capacity :100-500L

200L Tilting Vacuum Homogenizing Emulsifier (Cosmetic Production Equipment), Cream Homogenizing Machine(USER)

Uses:

It is suitable for the production of ointment and cream products in cosmetic factories .Especially for the emulsification preparation of materials with high viscosity and high solid content.

200L Tilting Vacuum Homogenizing Emulsifier (Cosmetic Production Equipment), Cream Homogenizing Machine(Composition)

Composition:

The unit is composed of pretreatment pot, vacuum emulsification stirring pot, vacuum pump, hydraulic system, feeding system, electrical control system, working platform and other parts. The unit is easy to operate, stable in performance, good in homogeneity, high in production efficiency, convenient in cleaning, reasonable in structure, small in floor space and high in automation.

200L Tilting Vacuum Homogenizing Emulsifier (Cosmetic Production Equipment), Cream Homogenizing Machine(Operater safey)

200L Tilting Vacuum Homogenizing Emulsifier (Cosmetic Production Equipment), Cream Homogenizing Machine is a kind of emulsification equipment widely used in cosmetics, food and chemical industries. During the operation of the emulsifying machine, attention should be paid to the phenomenon that it is easy to neglect and cause equipment failure or safety accidents, which will bring unnecessary waste and loss.

Below are the three necessary steps YALIAN technicians do before operating the equipment:

1. Preparation before start-up

First of all, check whether there are potential safety hazards in the emulsifying machine and the surrounding working environment, such as whether the pipeline and equipment appearance are complete or not, and whether there is water or oil leakage on the ground.

Then check strictly item by item against the production process and equipment operation and use rules to ensure that the conditions required by each rule are met.

1. Check the condition of lubricating oil and coolant, replace the turbid and invalid lubricating oil or coolant, and ensure that the liquid level is within the specified amount;

2. Check whether the switches and valves are in the original position, and manually check whether the action is sensitive and effective.

3. Check whether the safety devices such as limit position, evacuation and decompression are normal and effective;

4. Check whether there are sundries in the pot;

5. Check whether the power supply is normal, whether there is a fault display after power-on, etc.

2. Inspection during production

In normal production, it is most likely that the operator neglects to check the operation status of the equipment. Therefore, when the technicians of regular emulsification machine manufacturers go to the site for debugging, they will emphasize that the operators should pay attention to avoid improper use when operating the equipment, and check the working status at any time to avoid accidents. Illegal operations cause equipment damage and material loss. The sequence of start-up and feeding, cleaning method and selection of cleaning supplies, feeding method, environmental treatment during work, etc., are prone to equipment damage or safety problems due to carelessness, such as accidental foreign matter falling into the emulsification during use. Pot damage (the most common), damage and material scrap caused by not following the prescribed operation sequence to save trouble, material dripping to the ground during manual feeding is not cleaned up in time, causing personal safety problems such as slipping, falling, and bruising, etc.; Therefore, users need to strengthen supervision and prevention.

In addition, during the working process, if there are abnormal phenomena such as abnormal noise, peculiar smell, sudden vibration, etc., the operator should immediately check and handle them properly, and must put an end to the idea of waiting for the production to be completed, so as to avoid serious damage and loss caused by sick work.

3. Reset after production

The work after equipment production is also very important and easily overlooked.

Although many users have thoroughly cleaned the equipment as required after production, the operator may forget the reset step, which is likely to cause equipment damage or leave a safety hazard.

Pay special attention to the following points after using the equipment:

1. Empty the liquid, gas, etc. in each process pipeline. If automatic or semi-automatic equipment is used for pipeline transportation, attention should also be paid to handling the materials in the pipeline according to regulations;

2. Empty the sundries in the buffer tank and keep the buffer tank clean;

3. Clean the vacuum pump, check valve, etc. of the vacuum system (if it is a water ring vacuum pump, please pay attention to the jogging inspection before the next operation, if the rust is dead, you must manually remove it before powering on);

4. All mechanical parts are reset to normal state, and the inner pot and jacket keep the vent valve normally open;

5. Turn off the power supply of each branch and then turn off the main power supply.

There are tens of thousands of roads, and safe and standardized operation is the first. Bless careful management to ensure worry-free. Seriously operate according to the operation and maintenance instructions provided by the manufacturer, and require employees to develop good operating specifications and habits, which have a significant impact on production. Establish and be familiar with the complete and detailed operating specifications before, during and after production. Strict implementation of personnel can jointly create high-quality products and create a solid quality foundation for corporate benefits.

200L Tilting Vacuum Homogenizing Emulsifier (Cosmetic Production Equipment), Cream Homogenizing Machine(Features)

Features:

The tank cover is manual (automatic) lifting type, and the materials in the water and oil pot can directly enter the emulsification pot under vacuum through the conveying pipeline. The heat conduction medium in the interlayer of the pot is heated to realize the heating of the material, and the heating temperature can be set arbitrarily and controlled automatically. The material can be cooled by adding cooling liquid in the interlayer, which is simple and convenient to operate, and an insulation layer is provided outside the interlayer. Homogenizing system and stirring system can be used separately or at the same time. Micronization, emulsification, mixing, mixing and dispersion of materials can be completed in a short time. The part in contact with the material is made of high-quality stainless steel (commonly used 304, medical 316L), the inner surface is mirror-polished, the vacuum stirring device is hygienic and clean, and it is manufactured with hygienic standards in compliance with GMP regulations. It is an ideal cream production equipment for customers.

200L Tilting Vacuum Homogenizing Emulsifier (Cosmetic Production Equipment), Cream Homogenizing Machine(Main technical parameters)

Main technical parameters:

| Model |

YIF-100

|

YIF-200

|

YIF-300

|

YIF-500

|

|

Capacity

|

100 L

|

200 L

|

300L

|

500 L

|

| Vacuum |

-0.09 Mpa

|

-0.09 Mpa

|

-0.09 Mpa

|

-0.09 Mpa

|

|

Temperature

|

≤120 ℃

|

≤120 ℃

|

≤120 ℃

|

≤120 ℃

|

|

Jacketed pressure

|

Atmospheric pressure

|

Atmospheric pressure

|

Atmospheric pressure

|

Atmospheric pressure

|

|

Scraper agitator speed

|

0-60r/min

|

0-60r/min

|

0-60r/min

|

0-60r/min

|

|

Homogenizer speed

|

2880r/min

|

2880r/min

|

2880r/min

|

2880r/min

|

|

Power

|

50Hz

380V±10%-15%

|

50Hz

380V±10%-15%

|

50Hz

380V±10%-15%

|

50Hz

380V±10%-15%

|