NaN / 0

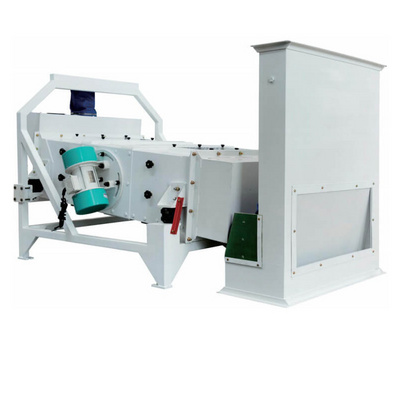

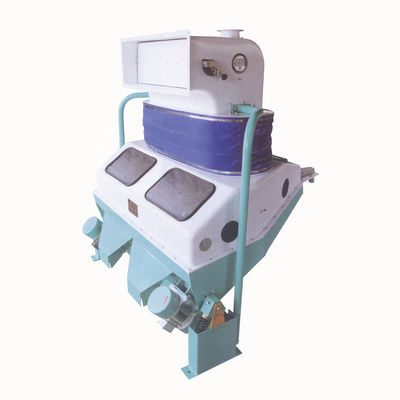

rice sesame seed processing machine mobile grain seed cleaning grading machine for wheat maize paddy gravity separator machine

Get Latest Price

US$ 7600

≥1 Pieces

US$ 7400

≥2 Pieces

US$ 7200

≥3 Pieces

Quick Details

Place of Origin:

Hebei, China

Brand Name:

Bicystar

Dimension(L*W*H):

8500*2100*3600mm

Type:

Farm Equipment

Product Details

rice sesame seed processing machine mobile grain seed cleaning grading machine for wheat maize paddy gravity separator machine

Products Description

|

Product Name

|

5XFZ-15A comblned seed cleaner

|

Certification

|

ISO9001:2008, SGS

|

|

Processing Material

|

wheat, maize, cassia seed, quinoa seed, sesame, beans etc

|

Brand

|

Bicystar or OEM

|

|

Total Power

|

22.5 kw

|

Size

|

2800*1500*1850mm

|

|

Function

|

Remove dust, impurities from good seed

|

Exported Country

|

Australia, Africa, Southest Asia, North America, South America, Europe

|

|

Warranty

|

1 Year

|

Weight

|

3600 KG

|

Brief Introduction:

The machine is suitable for efficient cleaning of all types of grains and seed. Gentle feeder and the belt guard provide efficient cleaning of grain without causing any damage to the particles.

High in functionality, The shoes of the machine can easily be replaced for different type of cleaning.

Working Principle:

The primary method of seed cleaning is the air-screen separator. It uses a combination of air and screens to separate seed based on size, shape, and density. The widely-use units come in a variety of models with two to eight vibrating screens. In all cases, cleaning principles are the same.

The grains are fed into the hopper where they are evenly distributed by a feedroller and transferred through a controlled gate on the top sieve. In the process the grains are subjected to primary aspiration by the use of air trunk which drains off chaff, straw, dust or deceased grains. Then the material is passed through sieve layer for separation accord-ing to their width and thickness. After the separation, the graded material is subjected to air sifter and aspiration chamber where remaining light particles are sucked off by a strongupward draught of air. The graded material and the impurities are automatically dischargedin separate chutes.

of dust.

Related Products

Hot Searches