NaN / 0

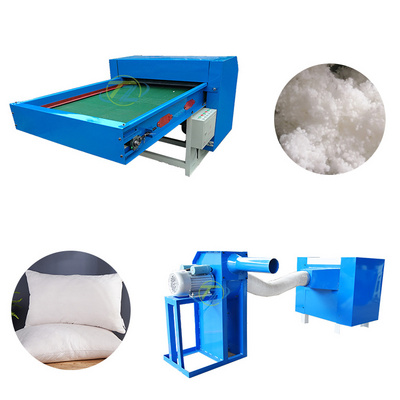

Commerical new type fiber opening process machine pillow filling and making machine

Get Latest Price

US$ 3800

≥1 Sets

Quick Details

Place of Origin:

Henan

After-sales Service Provided:

Video technical support, Field installation, commissioning and training, Field maintenance and repair service

Name:

Soft Toys Dolls Filling Stuffing Machine

Application:

Filling Pillow

Product Details

Commerical new type fiber opening process machine pillow filling and making machine

Product Description

The fiber clearing machine (also known as the cleaning machine, the opening machine, the cleaning machine, etc.) is a mechanical centrifugal force generated by the high-speed operation of the combing device and the licker to eliminate the impurities in the brocade and loosen the lint, rolling into Tablet, easy to use.

Application:

This machine can be widely used in a variety of chemical fiber, hemp, cotton, wool, textile waste yarn, waste clothing, textile trim, non-woven fabrics and other raw materials. Applicable to textiles, toys, clothing, shoes, knitted chemical fiber, waste processing and other industries.

Working principle:

The batt that needs to be processed is evenly spread on the feeding cotton curtain and pulled to the licker roller. Due to the rotation of the roller, the cotton layer is continuously fed under the strong grip of the cotton roller, and the saw teeth are hooked and rubbed against the cotton wool.

When the force is greater than the holding force it receives, the combed fibers in the batt are gradually taken away by the licker. The cotton wool is separated into a single fiber state, and under the high speed operation of the licker roller, a large centrifugal inertia force is generated, and the impurities are continuously ejected along the tangential direction of the outer circle of the roller.

Parameter:

|

Item |

Type |

dimension (mm) |

power |

Thorn roller length |

Thorn roller diameter |

weight |

capacity |

|

Single roller |

1010 |

2000x1700x1150 |

5 .5kw |

1000 mm |

250mm |

500kg |

100kg-200kg |

|

Double rollers |

210 |

2900x1700x1150 |

1 1 kw |

1000 mm |

250mm |

1000kg |

100kg-200kg |

|

Three rollers |

310 |

4000x1700x1150 |

1 6 .5kw |

1000 mm |

250mm |

1500kg |

100kg-200kg |

|

Four rollers |

410 |

5100x1700x1150 |

2 2 kw |

1000 mm |

250mm |

2000kg |

100kg-200kg |

|

Five rollers |

510 |

6200x1700x1150 |

2 7 .5kw |

1000 mm |

250mm |

2500kg |

100kg-200kg |

|

Six rollers |

610 |

7300x1700x1150 |

3 3 kw |

1000mm |

250mm |

3000kg |

100kg-200kg |

Packaging & Shipping

Our Services

Hot Searches