NaN / 0

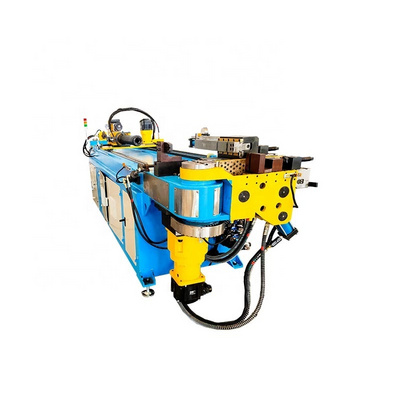

100CNC-2A-1S 101mm China cnc 3d Mandrel Bender rotary draw tube and Pipe Bending Machine

Get Latest Price

US$ 28500

≥1 Sets

Quick Details

Bending Radius (mm):

40 - 420

Max. Bending Angle (Deg):

190

Bending Precision (Deg):

0.1

Place of Origin:

Jiangsu, China

Product Details

Products Description

Full Automatic Pipe and Tube Bending Machine

Full-automatic pipe bending machine equipped with PLC or IPC which manage Bending (Y), Feeding (B) & Rotation (C) in a complete automatic cycle.

Ranging from 10mm up to 220mm OD these machines are suited for use in a wide range of pipe manufacturing sectors and industries. Available in different versions, there's all three axis are automatic in a single stack machine.

There’s also the option to add push bending function, left and right bending function, more stacks,and so on.

The series comes equipped with easy-to-operate touchscreen controls, or with the latest user-friendly 3D bending software. This stores tooling configuration, allows spring-back compensation, and boasts anti-collision technology, amongst other features.

Feature

* Interactive PLC touch screen offers easy access to auto and manual operating modes.

* System diagnostics and multiple language capability.

* Fully hydraulic clamping on clamp die and pressure die.

* Bending (Y-Axis): Controlled by Servomotor or by Hydraulic.

* Feeding (B-Axis): Controlled by Servomotor.

* Rotating (C-Axis): Controlled by Servomotor.

* Equipped with adjustable speed valve on pressure die ensures the synchronization of bending.

* Air cooling system ensures the equipment long-time work stably under the high temperature.

* CE&ISO 9001:2000.

* System diagnostics and multiple language capability.

* Fully hydraulic clamping on clamp die and pressure die.

* Bending (Y-Axis): Controlled by Servomotor or by Hydraulic.

* Feeding (B-Axis): Controlled by Servomotor.

* Rotating (C-Axis): Controlled by Servomotor.

* Equipped with adjustable speed valve on pressure die ensures the synchronization of bending.

* Air cooling system ensures the equipment long-time work stably under the high temperature.

* CE&ISO 9001:2000.

Options

*

IPC Controlling

* Double/Triple/Quadruple Stack (Different Radius on one pipe bending)

* Pipe Push Bending Function(Big Radius)

* Extra Mandrel Length

* Left&Right Head Bending

Pipe bending Macine Push bending for large radius (Optional)

Tube bending Machine multi-layer type

(Optional)

|

Model

|

38CNC-2A-1S

|

50CNC-2A-1S

|

63CNC-2A-1S

|

76CNC-2A-1S

|

|

Max Capacity

|

¢38.1 (1.5”)×2mm

|

¢50.8 (2”)×2mm

|

¢63.5 (2.5”)×4mm

|

¢76.2 (3”)×5mm

|

|

Bending Degree

|

0-190°

|

0-190°

|

0-190°

|

0-190°

|

|

Bending Radius

|

10-200mm (for machine)

|

15-250mm (for machine)

|

20-300mm (for machine)

|

25-350mm (for machine)

|

|

Min Bending Radius

|

R≥1.5D (for pipe)

|

R≥1.5D (for pipe)

|

R≥1.5D (for pipe)

|

R≥1.5D (for pipe)

|

|

Mandrel Length

|

2300mm (can be customized)

|

2500mm(can be customized)

|

3000mm(can be customized)

|

3200mm(can be customized)

|

|

Max Bending Speed

|

90°/s

|

65°/s

|

60°/s

|

45°/s

|

|

Bending Accuracy

|

±0.1°

|

±0.1°

|

±0.1°

|

±0.1°

|

|

Motor Power

|

4 Kw

|

5.5 Kw

|

7.5 Kw

|

7.5 Kw

|

|

|

|

|

|

|

|

Model

|

89CNC-2A-1S

|

114CNC-2A-1S

|

129CNC-2A-1S

|

168CNC-2A-1S

|

|

Max Capcity

|

¢89 (3.5”)×8mm

|

¢114 (4.5”)×8mm

|

¢129(5”)×12mm

|

¢168(6.5”)×16mm

|

|

Bending Degree

|

0-190°

|

0-190°

|

0-190°

|

0-190°

|

|

Bending Radius

|

30-450mm (for machine)

|

40-550mm (for machine)

|

50-650mm (for machine)

|

60-850mm (for machine)

|

|

Mini Bending Radius

|

R≥1.5D (for pipe)

|

R≥1.5D (for pipe)

|

R≥1.5D (for pipe)

|

R≥1.5D (for pipe)

|

|

Mandrel Length

|

3800mm(can be customized)

|

4500mm(can be customized)

|

4600mm(can be customized)

|

6500mm(can be customized)

|

|

Max Bending Speed

|

40°/s

|

25°/s

|

20°/s

|

10°/s

|

|

Bending Accuracy

|

±0.1°

|

±0.1°

|

±0.1°

|

±0.1°

|

|

Motor Power

|

11 Kw

|

15 Kw

|

18.5 Kw

|

22 Kw

|

Tool & Accessories

STANDARD MATERIAL: 45# STEEL

Optional Materials:

* Ampco Bronze- Mandrel&Wiper die for Stainless Steel Pipe

* Nylon- Bending die,Clampe die&Pressure die for Aluminum Pipe

* Cr 12-For other pipe material

* Nylon- Bending die,Clampe die&Pressure die for Aluminum Pipe

* Cr 12-For other pipe material

Packing Details

FAQ

What kind of pipe materials can bend ?

Carbon Steel ,Stainless steel ,Aluminum ,Copper pipes, tubes.profiles.

Boiler bank tubes bending

Condenser tubes bending

Wheelbarrow pipe bending

Exhaust pipe bending

Automobile pipe bending

Solid bar bending

Garage door profile bending

How to choose pipe/tube bending machine

According following information to choose pipe/tube bending machine type:

1)Pipe/tube materials

2)Max. outside diameter of the pipe/tube

3)Wall thickness range of the pipe/tube

4)Max bending radius (CLR) if possible (general 1.5*OD)

5)Bending drawing or photos ,samples if possible

Do you provide training to operating pipe bending machine?

1)Will provide operating video and manual with machine.

2)Also welcome to training at our factory, we will arrange everything at our factory.

Any optional functions for pipe bending machine

1)Servo motor for axis: 2axis(standard for CNC type),3axis,4axis,5axis,6axis..

2)Control System: PLC(strandard) or IPC

3)Bending mould layer: single layer(standard) ,double layers,triple layers and more.

4)Push bending function: V

5)Hole Punching function:E

What about your machine main component

1) PLC: Japan Mitsubishi

2) Servo motor: Japan Mitsubishi

3)Hydraulic system: Japan Yuken

4)Main Motor: Siemens

5)Electric parts: Schneider

What about your machine warranty?

One year warranty after machine reached customer's workshop.

And use famous brand components for long working lifespan.

What certificate for pipe bending machine

We have ISO certificate for our factory and CE Certification for our machine.

What delivery time for pipe bend machine

30 working days after received advanced payment.

What price term for pipe bending machine

Alibaba.com Trade Assurance accepted. T/T and LC accepted.

Carbon Steel ,Stainless steel ,Aluminum ,Copper pipes, tubes.profiles.

Boiler bank tubes bending

Condenser tubes bending

Wheelbarrow pipe bending

Exhaust pipe bending

Automobile pipe bending

Solid bar bending

Garage door profile bending

How to choose pipe/tube bending machine

According following information to choose pipe/tube bending machine type:

1)Pipe/tube materials

2)Max. outside diameter of the pipe/tube

3)Wall thickness range of the pipe/tube

4)Max bending radius (CLR) if possible (general 1.5*OD)

5)Bending drawing or photos ,samples if possible

Do you provide training to operating pipe bending machine?

1)Will provide operating video and manual with machine.

2)Also welcome to training at our factory, we will arrange everything at our factory.

Any optional functions for pipe bending machine

1)Servo motor for axis: 2axis(standard for CNC type),3axis,4axis,5axis,6axis..

2)Control System: PLC(strandard) or IPC

3)Bending mould layer: single layer(standard) ,double layers,triple layers and more.

4)Push bending function: V

5)Hole Punching function:E

What about your machine main component

1) PLC: Japan Mitsubishi

2) Servo motor: Japan Mitsubishi

3)Hydraulic system: Japan Yuken

4)Main Motor: Siemens

5)Electric parts: Schneider

What about your machine warranty?

One year warranty after machine reached customer's workshop.

And use famous brand components for long working lifespan.

What certificate for pipe bending machine

We have ISO certificate for our factory and CE Certification for our machine.

What delivery time for pipe bend machine

30 working days after received advanced payment.

What price term for pipe bending machine

Alibaba.com Trade Assurance accepted. T/T and LC accepted.

Recommend Products

Hot Searches