NaN / 0

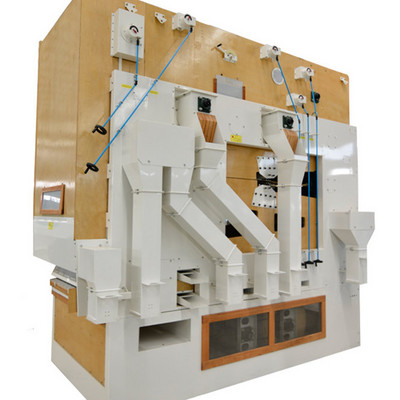

Agriculture Machine 5X Seed Cleaning Machine Red Kidney Bean Cleaning Machine Air Screen Seed Cleaner

Get Latest Price

US$ 12000

≥1 Sets

US$ 11500

≥3 Sets

Quick Details

Place of Origin:

Henan, China

Brand Name:

Hyde-Maosheng COFCOET

Dimension(L*W*H):

3900x1940x4060 mm

Type:

Air-Screen Super Fine Cleaner

Product Details

Agriculture Machine 5X Seed Cleaning Machine Red Kidney Bean Cleaning Machine Air Screen Seed Cleaner

Product Description

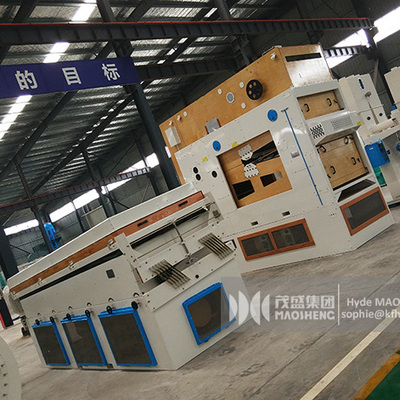

Hyde Machinery (Maosheng Group)

- Seed processing plant: 1~15 t/h

- Flour mill plant: 40~1000 t/d

- Manufacturer since 1976

5X Air Screen Cleaner Fine Cleaning

1) Function: fine cleaning to remove impurities, broken and abortive grains; grading seeds according to sizes.

2) Application: cereal grains and seeds.

3) Capacity: up to 12t/h (wheat).

5X air screen seed cleaner has been developed specially for flexible, high quality cleaning for grains and seeds. It can be used for pre-cleaning and intensive cleaning, but mainly for seed cleaning.

Working Principle of 5X Air Screen Cleaner

Seeds and grains can be separated from impurities for different physical and mechanical properties.

Separation is completed by:

1. Fans (air blowers): by different weight and aerodynamic characteristics.

2. Screens: according to different width and thickness sizes of seeds.

Excellent cleaning and grading function is accomplished by variable screen configuration, pre and after suction system, and air lifting blowers at the bottom. Closed, bolted and painted steel construction ensures the long service life and safe operation .

Application of 5X Super Fine Seed Cleaner

5X air screen cleaners are widely used for cleaning of grains and seeds, such as wheat, barley, lentils beans, rice, maize, spices, grass seeds and forestry seeds.

The multi-layer cleaning screens are changeable easily for different processing requirements.

5X Air Screen Fine Cleaner in Seed Cleaning Plants (maize, wheat, paddy, etc)

Advantages of 5X Air Screen Cleaner

1) Multi-layer screens are installed in opposite directions, products discharge at lowest layer, good cleaning for large and small impurities.

2) Upper and lower screen boats are installed in opposite directions, good dynamical balance for stable running.

3) Easy interchangeable screens are flexible for different processing requirements.

4) Positive and negative pressure blower systems are installed at top or external and bottom, twice remove light impurities and diseased seeds.

5) Screen frames, light impurity settling chamber and feeder parts are made of high quality wood, good sealing and vibration absorption performance, whole machine running with low noise.

6) Wide adjustable range and easy adjustment realize fine cleaning process easily.

7) Integral steel frame rubber ball tray for screen cleaning, easy to clean the sieve and machine.

8) Safety guard is equipped for every moving part to ensure safe operation.

9) Box-type screen body structure efficiently reduce dust content in workshop.

10) Symmetric machine structure, products discharge system can be installed left or right according to site conditions of customer.

Technical Parameters

Technical Specification of 5X Air Screen Cleaner

|

Model |

5X-5 |

5X-10 |

|

Overall Dimension (L×W×H) |

3200×1920×3600 mm |

3790×1940×4060 mm |

|

Total Weight |

3250 kg |

3600 kg |

|

Rated Capacity (wheat) |

5 t/h |

10~12 t/h |

|

Total Air Inflow |

8200 m3 |

12520 m3 |

|

Power |

||

|

Top Air Blower (Optional) |

4-72N0-5A, 7.5 kW |

4-79N0-6A, 11kw |

|

Sieve Vibration Motor |

2.2 kW |

Y132S-8, 2.2 kW |

|

Bottom Lifting System Motor (VVVF Motor) |

3.0 kW |

3.0 kW |

|

Feeding Motor (VVVF Motor) |

1.5 kW |

WR41-Y0.75-4P-1.68-M1, 1.5kW |

|

Total Power |

6.7 kW |

6.7kW |

|

Screen |

||

|

Screen Type |

Pierced Screen |

|

|

Screen Dimension (L×W) |

800×1250 mm |

|

|

Frequency |

300(80~400) /min |

|

|

Amplitude |

30 mm |

|

|

Layers and Number |

4 layers, 7 pieces |

5 layers,15 pieces |

|

1st layer |

1 piece, round hole |

3 pieces, slot hole |

|

2nd layer |

2 pieces, slot hole |

3 pieces, slot hole |

|

3rd layer |

2 pieces, slot hole |

3 pieces, slot hole |

|

4th layer |

2 pieces, slot hole |

3 pieces, slot hole |

|

5th layer |

/ |

3 pieces, slot hole |

Notes:

1. Individual machine will be supplied with 1 set of screens (7 pcs or 15 pcs), no top blower.

2. Machine can be converted to different cleaning programs, screens shall be changed accordingly.

3. Above technical data can vary due to continued development, or different machine configurations.

Related Products

Grain and seed cleaning machines:

Pre-cleaners, fine cleaners, rotary cleaners, seed graders, seed gravity separators, indented cylinder, wheat paddy de-awner, destoner, vibration cleaner, rotary cleaner, air aspirator, cyclone dust collector, seed treater, seed dryers, elevators and conveyors, auto-packing scales.

Air Screen Fine Cleaner Seed Gravity Separator Indented Cylinder Separator

Stone Separator Vibration Screen Cleaner Separator Rotary Cleaner

Hot Searches