NaN / 0

4kg/h Industrial Desiccant Rotary Wheel Dehumidifier

Get Latest Price

US$ 1200

≥1 Sets

Quick Details

Place of Origin:

Jiangsu, China

Brand Name:

Kawasima

Voltage:

220V

Power:

4274

Product Details

Product Description

|

Model |

KAL-200 |

KAL-350 |

KAL-450 |

KAL-550 |

|

Capacity (20 o C, RH60%) |

0.7kg /h |

2.5kg /h |

3kg /h |

4kg /h |

|

Power Source |

220V/50Hz/1P |

|||

|

Heating Power/Current(W/A) |

1000/4.8 |

2500/13 |

3000/17 |

4000/19 |

|

Max. Power/Current(W/A) |

1200/6 |

3180/16 |

3774/19 |

4274/22 |

|

React. Air Flow (m3/h) |

70 |

130 |

214 |

248 |

|

Process Air Flow (m3/h) |

210 |

340 |

420 |

550 |

|

Available Ambient Temperature( o C ) |

0-60 |

0-60 |

0-60 |

0-60 |

|

Net Weight(kg) |

30 |

45 |

50 |

50 |

|

Gross Weight(kg) |

35 |

55 |

60 |

60 |

|

Measurement(WxDxH)(mm) |

400*750*465 |

600*950*645 |

600*950*645 |

600*950*645 |

|

Available Area (m2)(H=2.6m) |

20-50 |

40-60 |

60-80 |

80-100 |

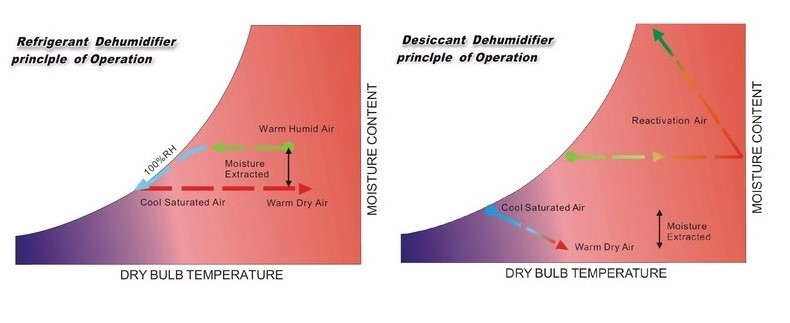

Refrigerant Dehumidifier VS Desiccant Dehumidifier

***Refrigerant Dehumidifier

The most common dehumidifier used is the refrigerant type. It is cheap to produce, easy to operate and effective in most domestic and commercial applications.

The primary benefit of a refrigerant dehumidifier is that it performs exceptionally well when used in warm, humid conditions.

One of the most important things to understand about a refrigerant dehumidifier is that the performance is directly related to the difference between the air dry bulb temperature and the air dew point temperature.

A refrigerant dehumidifier is essentially a re-arranged portable air conditioning unit, where the air is first passed across the evaporator coil to cool it, then across the condenser coil to heat it. The air becomes both warmer and drier.

The cold evaporator coil reduces the air temperature to a point where condensation occurs. Condensation formed on the cold coil then drips into a collection tray. Water is either drained away or collected in a container in the base of the unit.

As the surrounding air becomes drier the dew point is lowered, so the temperature necessary to created condensation on the cold evaporator coil also becomes lower. Even with an evaporator coil temperature of 0 o C , it is unlikely that the air will be reduced much below 10 o C dew point (it is worth nothing that air at 20 o C, 50% RH already has a dew point below10 o C ).

If the dew point of the air is already low, the coil temperature necessary to create condensation can easily be sub-zero. At this point, the operating efficiency of a refrigerant dehumidifier is greatly reduced. The evaporator begins to freeze as airborne water vapor makes contact with the cold tube surface. Defrosting of the coil is then necessary.

Defrosting is normally achieved by allowing hot refrigerant gas from the compressor directly into the evaporator coil. During the defrost cycle, the dehumidifier process ceases to remove water from the air.

***Desiccant Dehumidifier

A desiccant dehumidifier operates on a totally different principle to a refrigerant type.

The main benefit of a desiccant dehumidifier is that it performs exceptionally well when used in cooler climates, or when a low dew point is required. As there is no actual water produced during the process, these units can work effectively at sub-zero temperatures.

The rotor (the heart of the dehumidifier), is manufactured from alternate layers of flat and corrugated sheets, impregnated with an active component (desiccant). It is made to form a vast number of axial air channels running parallel through the structure. As air passes through these channels, moisture is transferred between the air and the desiccant in its vapor form.

The rotor is generally divided into two air zones which are separated by seals, the process sector (typically 75%), and the reactivation sector (typically 25%). The rotor is rotated slowly (approximately 0.5 rpm) using a small geared drive motor.

System air is pulled through the larger process sector where moisture is adsorbed from the air by the rotor material. The air leaves the dehumidifier warm and dry. Most of the heat gain is due to energy exchange during adsorption

A smaller heated air stream (usually fresh air) is pulled through the reactivation sector. This hot air is used to drive out moisture adsorbed into the rotor from the process air. The reactivation air leaves the rotor warm and wet. This air is normally exhausted to outside.

As these two opposing airflows pass through the rotor simultaneously, a continuous and automatic dehumidification process is achieved.

Hot Searches