NaN / 0

ANSI B16.5 ASME B16.5 Titanium threaded reducing flange Th pipe flange

Get Latest Price

US$ 32.3

≥5 Kilograms

US$ 29.5

≥20 Kilograms

US$ 25.7

≥100 Kilograms

Quick Details

Standard:

ANSI, ASME

Place of Origin:

Shaanxi, China

Brand Name:

LH

Model Number:

titanium flange

Product Details

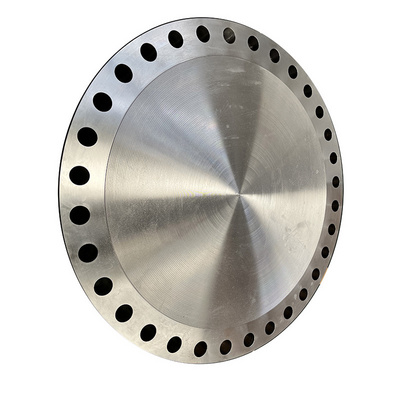

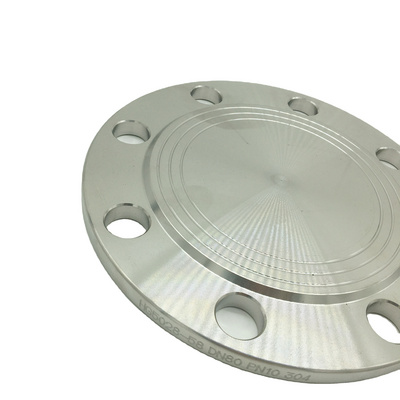

ANSI B16.5 ASME B16.5 Titanium threaded reducing flange Th pipe flange

Product Description

| Name | Titanium flange |

| Material Grade | Gr1,Gr2,Gr5,Gr7,Gr12 |

| Certificate | EN10204/3.1 |

| Standard | ANSI/ASME B16.5,DIN,EN1902-1, JIS etc. |

| Size | 1/2''~80''(DN10~3600) |

| Pressure | ANSI: Class 150-2500 DIN:PN6-PN250 |

| Technique | Forged and CNC Machined |

| Type | WNRF,SORF,BLIND,SW,PL |

| Flange surface | FF,RF,TG,RJ etc. |

| Application |

Boiler pressure vessels, chemical,petroleum,shipbuilding,pharmaceutical,metallurgy,machinery |

| Advantage |

1,Long servise lif 2,corrosion-resistant 3,High yeiled strength and tensilestrength |

Connection type of thread flange

The application of different grade titanium flange:

Due to the excellent corrosion resistance of titanium material, the pure titanium flange is much used for connecting the tube ends of the petrochemical project. It is also useful in equipment exit and entrance to connect the two devices.

Titanium alloy has the characteristics of light weight, high strength and good corrosion resistance, so titanium alloy flange is often used in oil drilling, marine engineering, machinery and equipment manufacturing industry in the key pressure parts of the connection.

Baoji Lihua has rich experience in forging and machining, which makes our titanium flange products kept good quality.

At the same time, to meet the specific requirements of customers, we also produce titanium flange according to customer drawings.

Detailed Images

1. Chemical requirements

| N | C | H | Fe | O | Al | V | Pd | Mo | Ni | Ti | |

| Gr1 | 0.03 | 0.08 | 0.015 | 0.20 | 0.18 | / | / | / | / | / | balance |

| Gr2 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | / | / | / | / | / | balance |

| Gr5 | 0.03 | 0.08 | 0.015 | 0.40 | 0.2 | 5.5-6.75 | 3.5-4.5 | / | / | / | balance |

| Gr7 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | / | / | 0.12-0.25 | / | / | balance |

| Gr12 | 0.03 | 0.08 | 0.015 | 0.25 | 0.15 | 2.0-3.0 | 2.0-3.0 | / | / | / | balance |

2. Tensile requirements

| Grade | Tensile strength(min) | Tensile strength(min) | Yeild strength(min) | Yeild strength(min) | Elongation |

|

Ksi |

Mpa | Ksi | Mpa | % | |

| 1 | 35 | 240 | 20 | 138 | 24 |

| 2 | 50 | 345 | 40 | 275 | 20 |

| 5 | 130 | 895 | 120 | 828 | 10 |

| 7 | 50 | 345 | 40 | 275 | 20 |

| 12 | 90 | 620 | 70 | 438 | 15 |

|

4.Product Description

|

||||||||||||||||

|

5. Available Flange types

|