NaN / 0

Vertical Spindle Roller Mill Coal Pulverizers types

Get Latest Price

US$ 28900

≥1 Sets

US$ 9500

≥5 Sets

Quick Details

Place of Origin:

Henan, China

Name:

Vertical Spindle Roller Mill Coal Pulverizers types

Processed Materials:

Limestone, calcite, barite,carbon black, ceramic, coal, ect

Input Size:

38-55 mm

Product Details

Vertical Spindle Roller Mill Coal Pulverizers types

Product Description

Applications of Vertical Spindle Roller Mill Coal Pulverizers types

Vertical Spindle Roller Mill Coal Pulverizers types is one advanced mill, adopting top technology domestic and abroad, and based on many years mill experiences. It can crush, dry, grind, and classify the materials.

Vertical Spindle Roller Mill Coal Pulverizers types can be widely used in such industries as cement, power, metallurgy, chemical industry, non-metallic mineral. It is used to grind granular and powdered materials into powder with required fineness.

Advantages of Vertical Spindle Roller Mill Coal Pulverizers types

1.Vertical Spindle Roller Mill Coal Pulverizers types low Investment Cost. This mill itself can crush, dry, grinding, classifying, so the system is simple, and occupation area is about 50% of ball mill system. In addition, it can be installed outside, so it will reduce a large number of investment costs.

2.Low Operation Cost. (1) High efficiency: roller compacted materials directly onto the grinding disc, so power consumption is low. Compared with ball mill, it saves energy consumption by 30% ~ 40%. (2)Less wear and tear: As the roller is not in direct contact with the disc, and material of the roller and liner is high quality, so life lime is long.

3.The stability of product quality. As the material stays in the mill for a short time, it is easy to detect and control the product particle size and chemical composition, to reduce duplication of milling, stable product quality.

4. Vertical Spindle Roller Mill Coal Pulverizers types Simple and reliable operation, Maintenance convenience, Environmental protection.

Click for More Information!!!

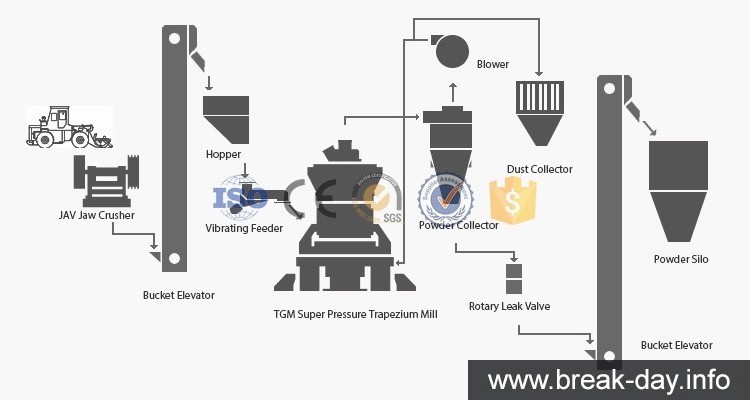

Working principle of Vertical Spindle Roller Mill Coal Pulverizers types

LM vertical mil has two pairs of grinding rollers, each pair of roller composed of two narrow rollers, mounted on the same axis and can rotate at different speeds. Disc roller and the relative sliding velocity between small and roller can swing, even if the roller sleeve and the disc after the liner wear can guarantee a good abrasive, will not affect the grinding effect. Material grinding process: hydraulic pneumatic roller device through the pressure applied to the material on the crushing of materials, the materials have been moved to crush the edge of disc, from the disc around the nozzle from the exhaust air to improve these materials to Separator.Meal to separate returns after a concentrated mill, fine powder was collected in the precipitator unloading. ring by adjusting the air valve, can change the product fineness can shide mill bed load material uniformity and stability, improving the grinding efficiency; coarse particles in the external circulation, helps reduce Fan power consumption and overall system power.

Structure of Vertical Spindle Roller Mill Coal Pulverizers types

Specifications of Vertical Spindle Roller Mill Coal Pulverizers types

Vertical Spindle Roller Mill Coal Pulverizers types for ore

Vertical Spindle Roller Mill Coal Pulverizers types for coal

Vertical Spindle Roller Mill Coal Pulverizers types for hard materials

Successful Case

The Grinding site of Vertical Spindle Roller Mill Coal Pulverizers types

Silica sand LM130N Grinding Plant in Indonesia

Raw Material:

silica sand

Output size:

325 mesh

Quantity:

2 sets LM130N

Capacity:

10-12 t/h

Application:

fiberglass

Brief Introduction:

Our Indonesian customer is using two sets of our LM130N to process silica sand. The final powder of 325 meshes will be used to make fiberglass. His raw materials have large content of Sio2., he finally choose our Vertical Spindle Roller Mill Coal Pulverizers types other than from other company. Because no other company’s grinding mill can process such hard materials.

Through using roller spacing limited device, removable roller sleeve and other advanced technologies, Vertical Spindle Roller Mill Coal Pulverizers types reduce the consumption of wearing parts and prolong the service life of wearing parts. Our Vertical Spindle Roller Mill Coal Pulverizers types solves the problems of grinding high hardness materials in the industry field.

Indonesia has always been our important market. We have an office in Indonesia. We will provide you the most comprehensive and timely service in Indonesia.

Click for More Information!!!

Packaging & Shipping

Vertical Spindle Roller Mill Coal Pulverizers types is exported to more than 130 countries and districts all over the world . We promise to ship about 45 working days after payment . The payment can be L/C, T/T and other negotiation .

Certifications

Vertical Spindle Roller Mill Coal Pulverizers types has obtained Patent Certificate , ISO international quality system certification , European Union CE certification , Russian GOST certification and many other honor certificates .

Our Services

- 24 hours online customer service, detailed and professional solution.

- Skilled engineers, scene investigation, free customized program solution.

- The purchase contract has a certain reputation guarantee, provide you the perfect product to your hands.

- After-sales service support, Expert technical training and operating instructions, site installation and commissioning, adhere to test equipment and visit our customers regularly.

- We offer all kinds of models, high-quality crushing and screening equipment parts.

Hot Searches