NaN / 0

High Quality PVC Fiber cable tray OEM ODM Manufacturer Fiber Duct Tray Optic Fiber Raceway for data center yellow

Get Latest Price

US$ 5

≥10 Pieces

Quick Details

Type:

Ladder Tray

Material:

Steel

Place of Origin:

Jiangsu, China

Brand Name:

A-RACK

Product Details

Product Description:

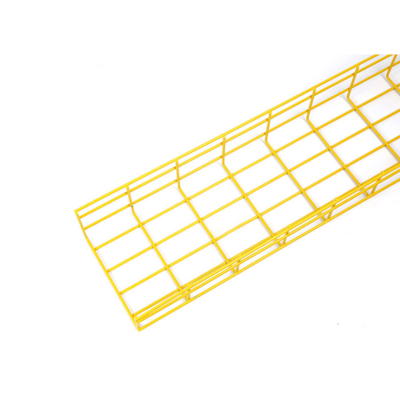

FiberworX Optical fiber cable tray

FiberforX

Product Structure

| Item No | Item name |

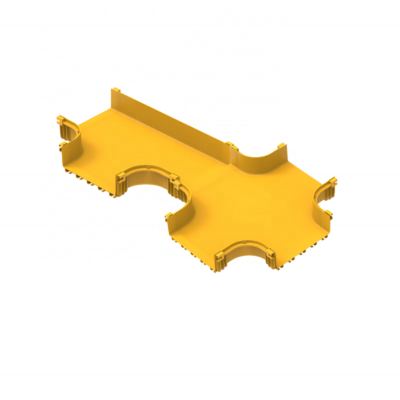

| 1 | 240 Horizontal Cross |

| 2 | 240 Connector |

| 3 | 240 Duct 400 |

| 4 | 240 Duct |

| 5 | 240 Inside(up)Bend |

| 6 | 240 Outside(up)Bend |

| 7 | 240 Horizontal Tee |

| 8 | 240 - 120 Vertical Vertical Tee |

| 9 | 240 - 120 Horizontal Tee |

| 10 | 240 Horizontal Bend |

| 11 | 240 Duct 2210 |

| 12 | 120 Outlet Cover |

| 13 | 120 Outlet |

| 14 | 120 Duct |

| 15 | 120 Connector |

| 16 | 120 Vertical Tee |

| 17 | 120 Horizontal Cross |

| 18 | 120 Inside Bend |

| 19 | 120 Outside(down)Bend |

| 20 | 120 Horizontal Tee |

Technique parameter:

Characteristic

Easy to install,good flame retardant property,and is the best ideal facilities for optical protecting.

Traces on the cable for the room.

Protects the fiber from damage.

Ensure that the fiber meets the minimum turning radius

Supports multi-directional fiber alignment.

Provide redundant storage space jumper.

solate different types of cables.

Semi-enclosed structure, easy installation, alteration fiber.

Optional cover

Main parameters

1,Thermal rating:-25℃~+55℃;

2,Relative humidity:less than 85%(+40℃);

3,Atmospheric pressure:70kpa-106kpa;

4,Even color,smooth and clean.without flash,dark bubble,shrinkage,depression or mechanical damage,and other defects:

5,Dielectric performance test is done before and after constant temperature test,the communication 4200V(rad value)industrial frequency sine wave voltage is applied between internal and external surface for 1 minute.After test insulation resistance is no less than 20M.

6,After low temperature test,the sample does not appear breaks or brittle fracture;

7,After the stated conditions of aging,impact test,the sample doesn’t crack or brittle fracture;

8,Plastic combustion performance:

(1)Plastic injector,extruder products combustion performance accords with level FV-0 of GB/T2048-1996;

(2)Corrugated pipe combustion performance accords to level of FV-2 of GB/T2048-1996.

Partial

installation

renderings