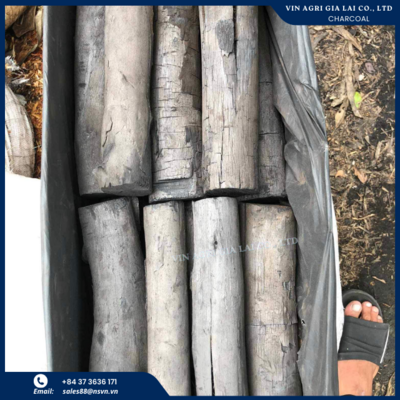

White Charcoal is produced from a variety of wood sources such as eucalyptus, coffee, lychee, longan, and ironwood. Typically, each branch used is about 5-12 cm in diameter and approximately 50 cm in length. The name "white charcoal" originates from its whitish surface, which doesn't leave your hands dirty when handled. White charcoal boasts an exceptionally high carbon content (> 89%), lacks impurities, and possesses remarkable hardness.

The process of creating white charcoal is notably more intricate compared to standard black charcoal production.

1. First, logs are stacked vertically inside the kiln, and firewood is burned over a hole in the kiln. The temperature in the kiln is maintained at or slightly above 87 to 100°C until the wood is completely dried.

2. Subsequently, the temperature is raised to thoroughly eliminate resin from the wood, causing the wood to become significantly denser and harder. The kiln temperature is gradually increased to a maximum of 1200°C. During this phase, the wood structure breaks down, releasing vapors that include methane...

3. Finally, the charcoal is gently scraped into barrels to facilitate cooling until it reaches a completely cooled state. Once cooled, Binchotan charcoal is ready for packaging.

This meticulous process ensures the production of high-quality white charcoal, prized for its purity and hardness.