NaN / 0

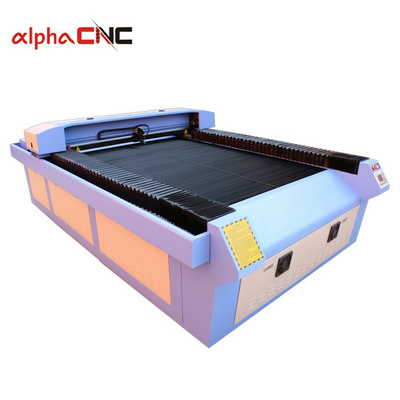

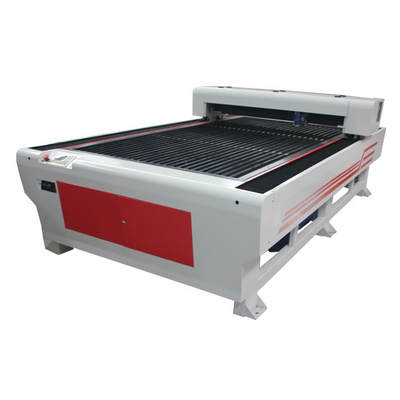

Ready To Ship!! New Product Wood Pattern Puzzle 1325 Low Cost Cnc Laser Cutting Machine

Get Latest Price

US$ 3300

≥1 Sets

Quick Details

Laser Type:

CO2

Cutting Speed:

0-40000mm/min

Cooling Mode:

WATER COOLING

Control System Brand:

Ruida

Product Details

Product Description

New Product Wood Pattern Puzzle 1325 Low Cost Cnc Laser Cutting Machinewood pattern laser cutting machine

Applicable Industries:

Advertising, arts and crafts, leather, toys, garments, model, embroidery, clipping, packaging and paper industry, Wood Working, engraving embroidery, crafts, RC airplanes, balsa models, kites, robotics kits, and clothing patterns.

Cutting and Engraving materials:

, jade, marble, glass, crystal, plastic, garments, paper, leather, rubber, ceramic, Hard Wood, MDF, Plywood, , Plastic, Acrylic, and other non metal materials. Can also engrave onto metals with the use of an additive laser marking material like "Cermark".

Specifications:

• Laser-type : Sealed CO2 laser tube, water-cooling, 10.6um

• Laser power: 80W(other wattages available)

• Machine Power: 220VAC

• Engraving area: 1200*900mm, 1300*900mm, 1400*900mm, 1400*1000mm, 1600*1000mm(other size available)

• Max engraving speed: 0-30,000mm/min

• Max cutting speed: 0-24,000mm/min

• Laser output control: 1-100% software setting

• Location precision: less than 0.01m

• Highest scanning precision: 50-1000DPI

• Operating temperature: 0 - 45C

• Operating humidity: 5- 95% non-condensing

• Minimum shaping character: English 1x1 mm

• Driving system: Micro-step motor and amplifiers

• Cooling mode: -based chiller and water flow sensor

• Auxiliary equipment: Vacuum/Exhaust fan, air-exhaust hose, air-assist pump

• Work surface: Iron honeycomb

• Controlling software: Ruida

• Compatible software: TAJIMA, CorelDraw, AutoCAD, Photoshop, ...and more

• File formats supported: JPG, BMP, PLT, DST, DXF, AI...

• Color separation: Uses color property to set function, speed, and laser power.

Standard Configuration:

Laser Cutter/Engraver, Water cooling pump and tank, Air Pump, Exhaust blower, Software and Software User Manual, Machine operation Manual, Software User Manual, Trouble Shooting Manual, Communication cable, Power cable, Lenses and Laser tube (80 Watts), Machine operation Manual, USB Communication cable.

Detailed Images

Easy to Use LCD Control Panel

User Friendly LCD control panel allows the user to quickly change selected program and modify machine operational conditions. You can Start, Stop, Pause, Reset, Datum, Test Fire, Outline engrave project area, Move the X or Y axis, LCD Viewing Display, Z-Axis up/down, Control Interior light, Emergency Stop, Lockout the operations with the Key.

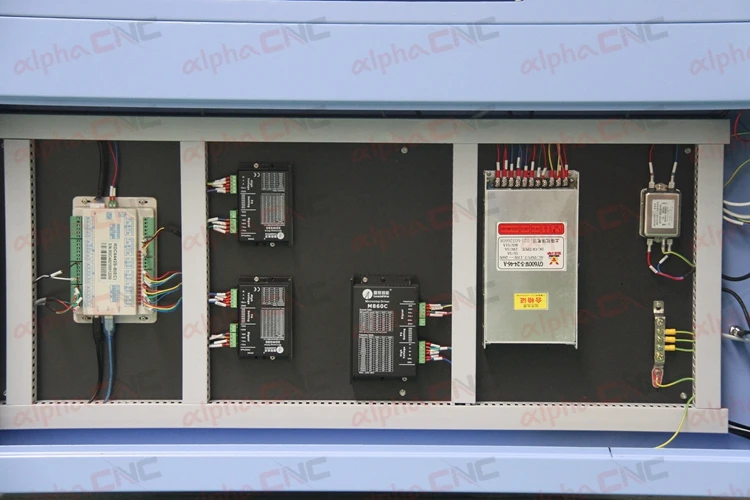

Dedicated Micro Processor Controller for great performance

The heart of the laser machine is the industry leading Ruida controller. The Ruida motion controller is connected to the computer by USB connection. The computer downloads the project to the laser motion controller and it does all the work, leaving the computer and operator free to work on the next project. The dedicated Ruida controller has RAM onboard to store large projects without re-downloading from your computer.

Laser tube

The standard laser tube is 80w. Alpha supplies 80-180 laser tube for your choice, you can choose according to your work and the workpiece thickness.

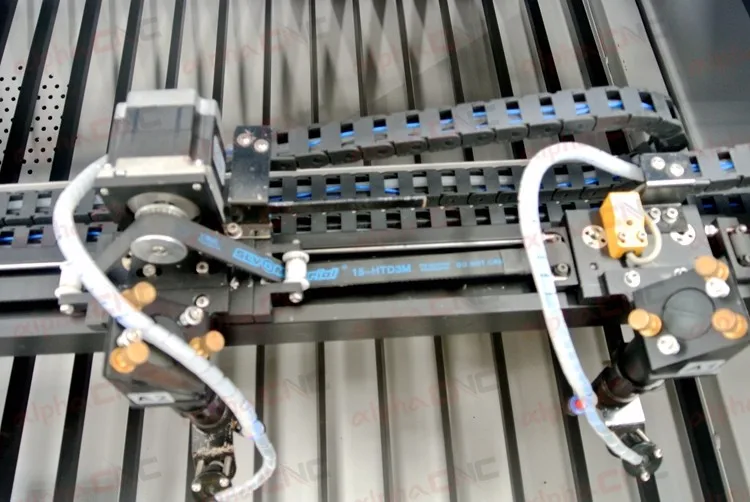

Transmission system

The guide liner is Taiwan Hiwin square rail, which is durable, after long time use, it will still have high precision. The belt is Shanghai Fulong brand, it is durable and hard deformed.

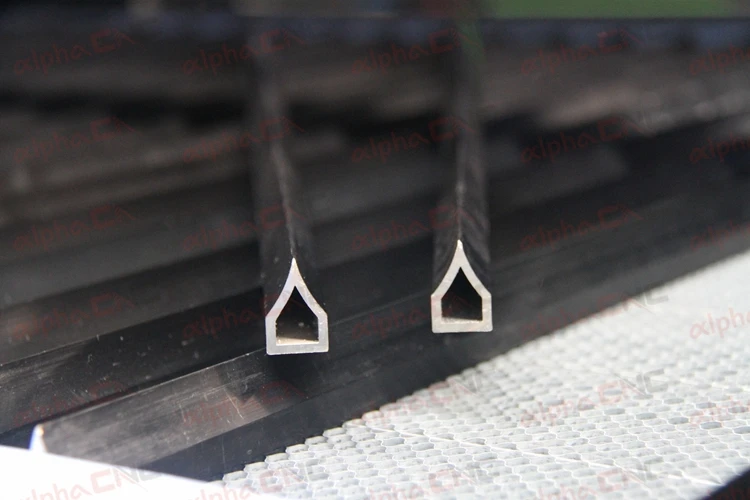

Table

Alpha supplies blade and honeycomb table for your choice, you can choose according to your requirement.

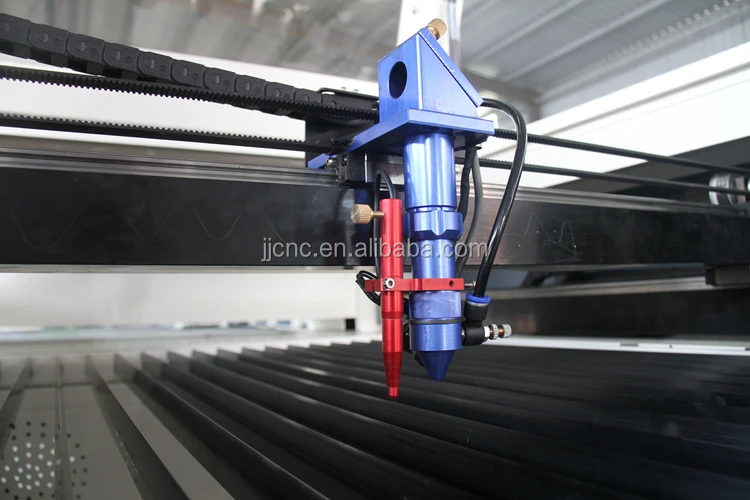

Air Pump

The air pump is used for three basic reasons. The primary reason is the push fumes away from the laser's focal lens. This protects the lens from contaminants which could destroy the lens. The second function of the air pump is to push air into the material's kerf as created by the laser beam. Air that is applied to the kerf will remove debris/fumes and allow the laser light to penitrate deeper through the material. The third reason is that the air will help to cool the material. If the laser cut/engraved material stays hot, then it could warp or shrink. This air pump is a diaphram style which does not require oil. Oil or water in the air line could be projected directly onto the focal lens. This air pump has a higher air flow rate and is quieter than other piston-stroke designs.

Blower / Fan / Vacuum

The vacuum blower creates an air flow to remove dust and fumes from the work area of the laser machine. It is important to remove the dust and fumes from the laser engraving areas because dust can settle onto the mirrors or lens. Dust on the mirrors or lens will create a focal point of the laser's heat and soon destroy the optics. The fumes need to be removed from the operator work area because they can be irritating and unhealthy. The blower can also be connected to a vaccum box to pull air through the work material.

Lens

American imported material made lens, making the lens with high quality.

Pass-Thru Doors

The laser machine frame is built with doors that allow materials to extend out the front and/or rear of the machine. The pass-thru is helpful when engraving or cutting material that cannot fit completely inside the machine. Examples: Engraving pictures onto a bathroom shower door. Rolls of fabric threaded into the rear door, engraved or cut, and then pulled out the front door. Engraving the front door to my house. Engraving very large mirrors or sheets of glass. The limits are endless.

Castor Wheels

The various models of laser machines can weigh from 300 to more than 1000 pounds. Every machine is equipped with castor wheels to make it easier to move it around the workshop or office. While the castor wheels are great for moving the laser machine around the building, the laser machine is also equipped with leveling pads. The leveling pads should be used for long term stabilization of the laser machine.

Laser Head

Alpha supply short and long laser head for your choice. short laser head usually for cutting, long laser head usually for engraving.

Option Parts

Multi-head

The multi-heads can work together, so the machine will have higher effectiveness.

Automatic up-down table

It is automatically, using two motors to lift the table. It often match with a rotary axis, when engraving 3D l objects or the objects height beyond the laser machine working height, the automatic up-down is necessary. Alpha use high quality ballscrew, the service time is much longer.

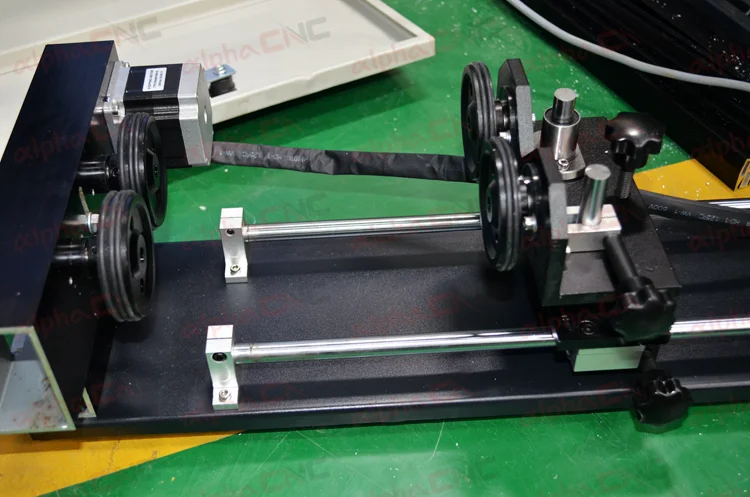

Rotary Axis

If you want to engrave bottle or other cylindrical objects, you should choose the rotary axis, it always together with the automatic up-down table.

Sample

Our Certificates

Packing & Delivery

About Alpha Cnc

FAQ.

Q1: This is the first time I buy the machine, is it easy to operate?

We can provide the operation manual or video for guiding. If it is hard for you learning, we can also help you by "Team viewer"online, with telephone or Skype explain.

Q2: How to choose a suitable machine?

You can tell us the working piece material, size, and the request of machine function. We can recommend the most suitable machine according to our experience.

Q3 :How can I trust your company and your products?

The whole production procedure will be under regular inspection and strict quality control. The complete machine will be tested to make sure they can work very well before being out of factory. The testing video and pictures will be available before delivery.

Q4.If machine have any problem after I ordered it, what could I do?

Free parts send to you in machine warranty period if machine have any problem. Free after-sales service life for machine, please feel free contact us if your machine have any problem. We will give you 24hours service from phone and skype.

Q5. Can I visit your factory?

Yes! We greatly welcome customers to visit our factory!

Q6. What's your date of delivery?

For standard machine, about 15 working days; For customized machine, about 20 working day.

Q7.MOQ?

Our MOQ is 1 set machine. We could send machine to your country port directly, please tell us your port name. There will be best shipping freight and machine price send to you.

Hot Searches