NaN / 0

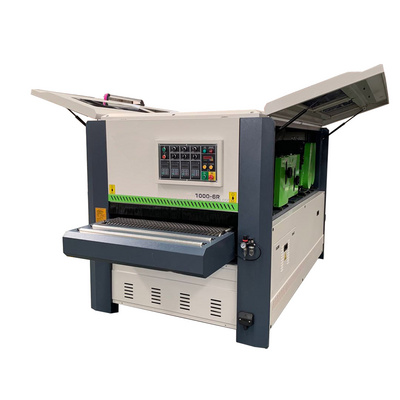

Automatic Brush Sanding Woodworking MDF Board Wood Sander Polishing Machine

Get Latest Price

US$ 1200

≥1 Sets

Quick Details

Place of Origin:

Shandong, China

Brand Name:

xingsai

Marketing Type:

Hot Product 2024

Power (kW):

15

Product Details

Product Description

Sheet Metal Deburring Machine Quality Control

This equipment is a dry abrasive belt model with double sand racks. It is mainly used for deburring, workpiece edge, hole

deburring effect, sanding the surface of the workpiece, making the contour edges around the surface of the workpiece and in the hole smooth and round, and realizing wire drawing, descaling, polishing, and slight pouring on the surface of metal sheets. Angle and other processing. The burrs generated in the processes of stamping, shearing, laser machine cutting, plasma cutting, etc. can be removed in all directions at one time. The processing process is safe and reliable, so that the workpiece can achieve perfect results.

This deburring machine support laser cutting machine, CNC stamping, various CNC processing or other machining deburring front production line. It can work for removal of parts surface, contour edge and hole edge burr and uniform chamfering.

deburring effect, sanding the surface of the workpiece, making the contour edges around the surface of the workpiece and in the hole smooth and round, and realizing wire drawing, descaling, polishing, and slight pouring on the surface of metal sheets. Angle and other processing. The burrs generated in the processes of stamping, shearing, laser machine cutting, plasma cutting, etc. can be removed in all directions at one time. The processing process is safe and reliable, so that the workpiece can achieve perfect results.

This deburring machine support laser cutting machine, CNC stamping, various CNC processing or other machining deburring front production line. It can work for removal of parts surface, contour edge and hole edge burr and uniform chamfering.

Machine Application

Xingsai plate polishing machine adopts high-quality continuously variable speed motor, which has high strength, large speed adjustment range, high speed adjustment accuracy, strong combination ability and stable performance. Optional automatic or manual adjustment of sand belts, multiple combinations of double sand racks, three sand racks, four sand racks or polishing wheel models for grinding, supports customization, suitable for various polishable metal surfaces, iron plates, stainless steel plates, aluminum plates, molds Burrs and other plates.

Features: accurate size, long service life, guaranteed material, low noise, easy operation and maintenance

specification

|

the main part of the equipment parameters

|

|

|

|

|

||

|

NO.

|

Working width

|

1300mm

|

|

|

||

|

1

|

motor

|

11kw+7.5kw

|

|

|

||

|

2

|

Conveyor belt motor

|

0.75*1

|

|

|

||

|

3

|

Keyboard plate

|

Maintenance control

|

|

|

||

|

4

|

Sanding belt

|

1970*1180mm

|

|

|

||

|

5

|

Conveyor belt

|

3100*980mm

|

|

|

||

|

6

|

Working thickness

|

0.03-120mm

|

|

|

||

|

7

|

Machine size

|

1750*1750*2100mm

|

|

|

||

|

8

|

Machine weight

|

910kgs

|

|

|

||

machine running video

Effect Display

Metal wide belt sanding machine is a double-roller water grinding and sanding machine, with the help of water spraying device and water circulation system, it adopts wet sanding to brushed and polished metal type and stone surface. The soft rubber roller made by special material and process, the grinding and sanding strength is easy to control, high precision and stable performance. Optical components, oscillating cylinders, electrical parts, bearings, etc. are treated with water-proof and rust-proof, with higher service life. Equipped with protection for overload, low air pressure, leakage, running belt and lack of equation, if any of the above fails, the equipment will automatically stop and emergency brake to ensure production safety.

All copper core motor,Powerful, stable operation and long service life.

Thickened conveyor belt,Strong tensile force, long-term use will not deviate, wear-resistant and durable.

sanding belt

1,a pair of abrasive belts, with chamfering sanding without dead angles.

machine frame

Control panel:One-key operation, simple and convenient, easy to use.

machine details

factory workshop truth

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Certifications

FAQ

Q:Why choose our machine?

A:We are polishing machine equipment MANUFACTURER, So we can offer better price and after-sale service and shorter delivery date.We have successfully exported to Europe, USA, South Africa, Southeast Asia and so on foreign countries. We all get good feedback.

Q: Can the machine be customized according to the special requirements of customers?

A: We have strong design & technical capacity, we can design and manufacture as per the customer's requirement.Please tell me your requirements first, then we can designed the suitable machine to you.

Q:How about delivery time?

A: 10-15days

Q: Do you have after sales support?

A: Yes, we have rich experience in handling after-sales issues via video or email.

Q: Do you have installation and training service in our local?

A: Currently, we have service partners in Portugal, Tukey and India. Portugal and Turkey partners provide service for the European area. In other areas, if needed, we will arrange an engineer from China.

Q: Do you have CE certification and other documents for customs clearance?

A: Yes, we have CE,At first we will show you after shipped we will give you CE/Packing list/Commercial Invoice/ Sales contract for customs clearance. If need, We can do other clearance documents, such as Certificate of Origin.

Q: How about warranty?

A: We provide a FREE ONE YEAR WARRANTY for machine parts. (Non-human factors) Lifetime technical support and service, and consumables at the lowest price.

You just need it, I'm just the professional!!

Just looking forward to service every customer,

like you!

Elena(Ms)

Hot Searches