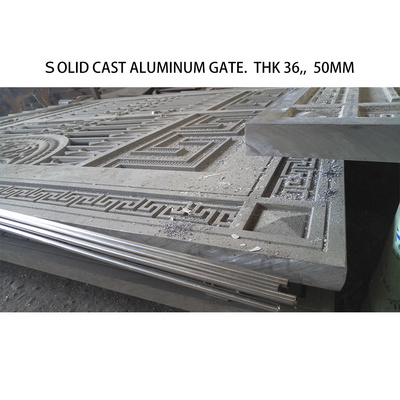

Our designer team designs

the reliefs on the surface of cast aluminum gates or railings in detail according to the styles and dimensions provided by the

customers, So that the customers can know the 3D effect of his products more clearly.