NaN / 0

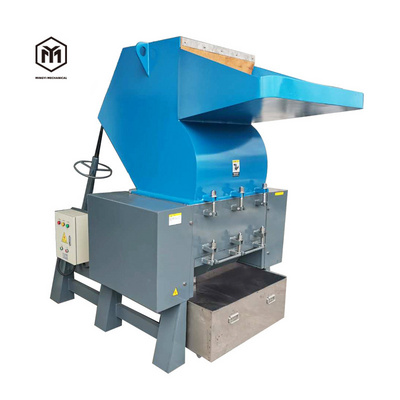

Functional small recycling machine plastic bone chicken shredder/ grinder/ crusher machine

Get Latest Price

US$ 1000

≥1 Sets

Quick Details

Output (kg/h):

80 - 250 kg/h

Feeding Size (mm):

1 - 100 mm

Output Size (mesh):

6 - 20 mesh

Power (kW):

2.2

Product Details

Functional small recycling machine plastic shredder/ grinder/ crusher for sale+8618737189043

Introduction of Herb crusher machine

This machine is a vertical crushing structure. The material is fed into the crushing chamber from the hopper. The rotating knife is used to rotate and impact, and the fixed knife and the movable knife are sheared at the same time. In addition, the machine is designed in accordance with the "GMP" standard. The whole machine is made of stainless steel, so that medicines, food, etc. can meet the national hygiene requirements. The whole machine is made of stainless steel, with simple structure, easy cleaning, low noise, and it is currently coarsely crushed. Very ideal equipment.

The coarse crusher is suitable for industries such as medicine, chemical industry, food, gold, and construction. For processing hard and difficult-to-pulverize materials, including pulverizing plastics and tree roots, it can also be used as a supporting equipment for the pre-process of micro-pulverization

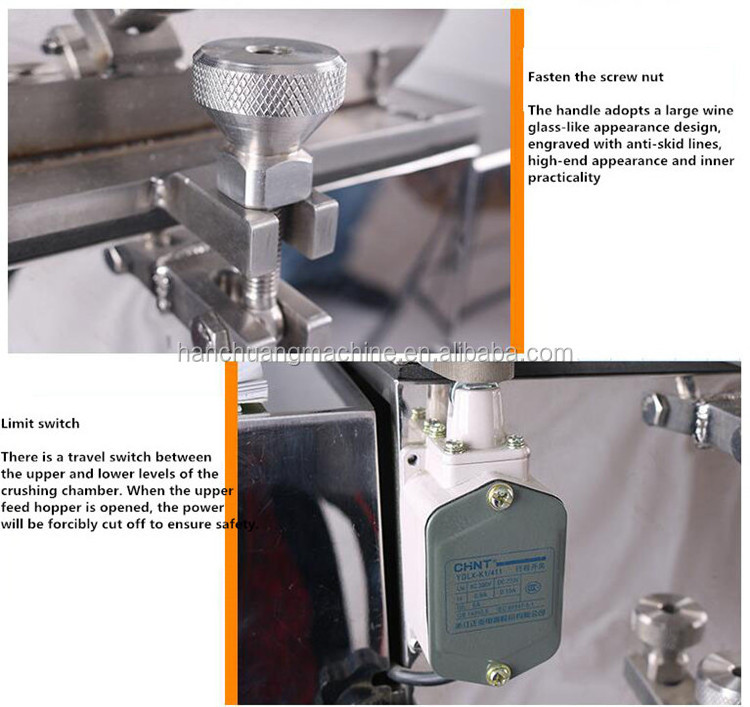

Details of Chemical materials crusher machine

Parameters of crusher machine

|

Model |

PE-180S |

PE-250S |

PE-400S |

PE-600S |

PE-800S |

|

Capacity(kg/h) |

80-150 |

120-250 |

200-400 |

300-500 |

500-1000 |

|

Voltage( v) |

220 |

380 |

380 |

380 |

380 |

|

Power |

2.2 |

4 |

7.5 |

15 |

22 |

|

Blade quantities |

9 |

6 |

12 |

18 |

14 |

|

Screen size(mm) |

Normal: 4/6/10mm, also can customized |

||||

|

Motor speed(r/min) |

720 |

690 |

600 |

490 |

450 |

|

Outlet size(mm) |

190*138 |

245*165 |

405*208 |

605*213 |

805*225 |

|

Machine size(cm) |

83*55*113 |

100*645*118 |

112*85*113 |

128*105*142 |

157*129*159 |

Application of crusher machine

Notice of crusher machine

1. the material should not contain excessive metal impurities, once entered will cause serious damage to the tool.

2. The rotation direction of the motor must be consistent with the requirements.

3. If there is abnormal noise during the production process, stop the machine for inspection immediately and continue production after troubleshooting.

4. Regularly check whether the screws and cutters of the equipment are loose, and reinforce them in time. If the tool is found to be severely worn, it should be ground or replaced in time. So as not to affect the overall crushing effect.

5. When the discharging is too slow or too fine, it may be that the screen is blocked and should be cleaned up in time.

6. This machine should be supervised by a special person during the working process. If the noise is abnormal, the power should be turned off immediately and the machine should be checked until the problem is eliminated before it can be turned on again. 7. The machine must not break flammable and explosive materials.

Mchine picture show:

Packaging & Shipping

Packaging & Shipping

1. Testing Machine before package

2. Package : Inside plastic bag, outside wooden case.

3. Shipping: By sea, By air.

By sea: if customer not urgently the machine, we advice by sea, even though by sea took time is long, but by sea reduce much money about the freight, and it is good for customer if the machine is heavy and big size.

By air: it is faster than by sea, but its freight is higher much than by sea, so this kind of type always suggest for light, small size and urgently demand machine.

Our Services

Pre-sale service

1.Related machines’s technical parameter will be supplied to customer.

2.According to customer’s factory size, factory layout can be provided in advance.

3. According to customer’s material cost, general formulation can be prepared well.

4.Special machine can be supplied as customer’s request.

5.Professional Advice about Market, machines, processing , materials, packing can be supplied

6. Suggesting professional ship agent or helping book ship as customer request.

After sale service :

1.Allocation chart as the buyer’s request will be supplied.

2.Operation manual will be supplied after shipment.

3.One year warrantee, life time maintenance with cost price.

4.Free easy broken spare parts will be sent with container .

5.First installation can be done by engineer.

6.Training workers in customer’s factory.

Hot Searches