NaN / 0

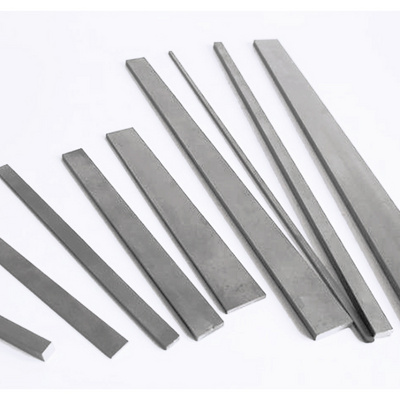

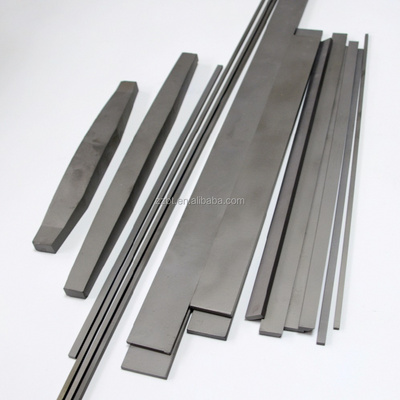

K10 K20 tungsten carbide strips plates and round bar in stock

Get Latest Price

US$ 56

≥10 Pieces

Quick Details

Warranty:

NA

Place of Origin:

Hunan, China

Brand Name:

LIHUA

Model Number:

M4~M16

Product Details

Product Description

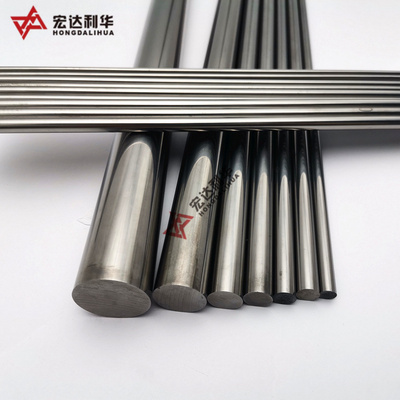

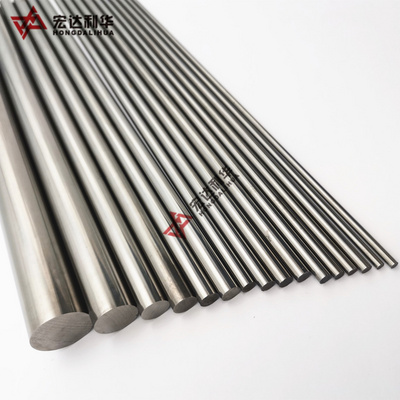

Tungsten Carbide Round Rods

Applications:

It is suitable for the production of various types electrical machine & electronic progressive dies and punches. And widely used in ceramics, printing machine, plastic, rubber, leather industry and cutting machines, CNC machine, CNC, PCB micro drill bits,etc.

Product Parameters

|

Details of Tungsten Solid Carbide Rods

|

|

|

|

Product name

|

Solid carbide Rod / Bar / Stick

|

|

|

OD tolerance

|

0.5um

|

|

|

Surface fineness

|

Ra0.025a

|

|

|

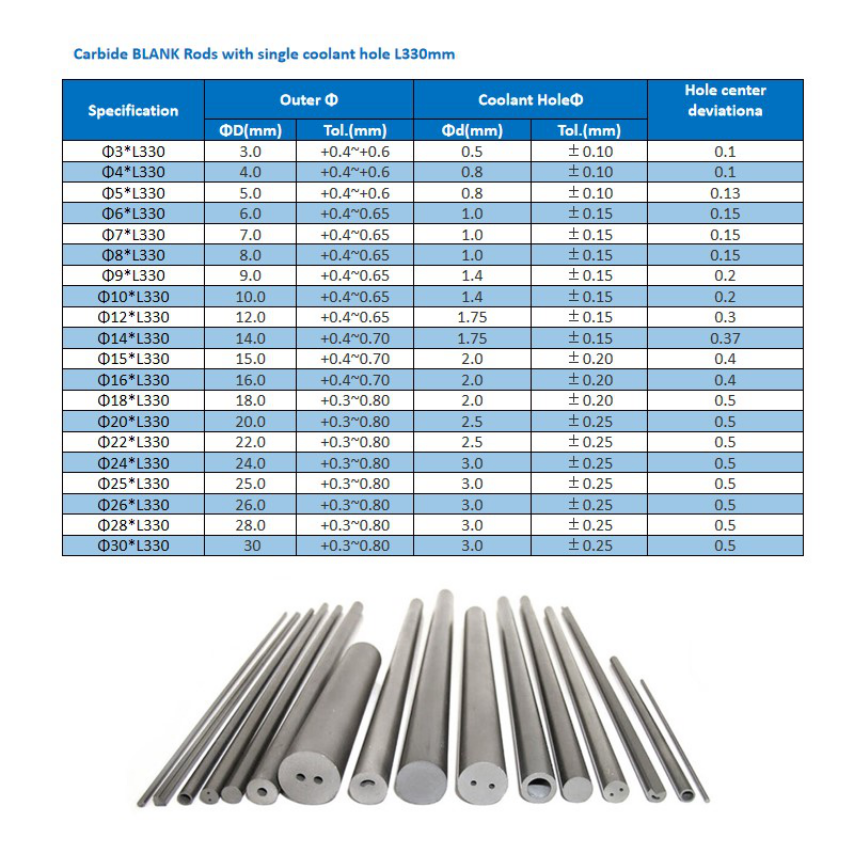

Sizes

|

Diamter:Φ0.5-Φ0.35mm,Length:100-330mm(diameter is Φ1.0-Φ6.0mm,lenght can up 700mm)

|

|

|

Type

|

Round(solid,hollow)

|

|

|

Grade

|

YL10.2, K20,K30 ,YL50,YU06A,YU06R,YF06,YH6F,YG11 etc.

|

|

|

Material

|

100% Tungsten Raw Materials

|

|

|

Physical performance

|

High Precision , hardness,strength, wear resistance .

|

|

|

Application

|

For production various types electrical machine & electronic progressive dies and punches.And ceramics, printing machine, plastic,rubber, leather industry and cutting machines.

|

|

|

Non-standard or Tolerance

|

Can be customized

|

|

|

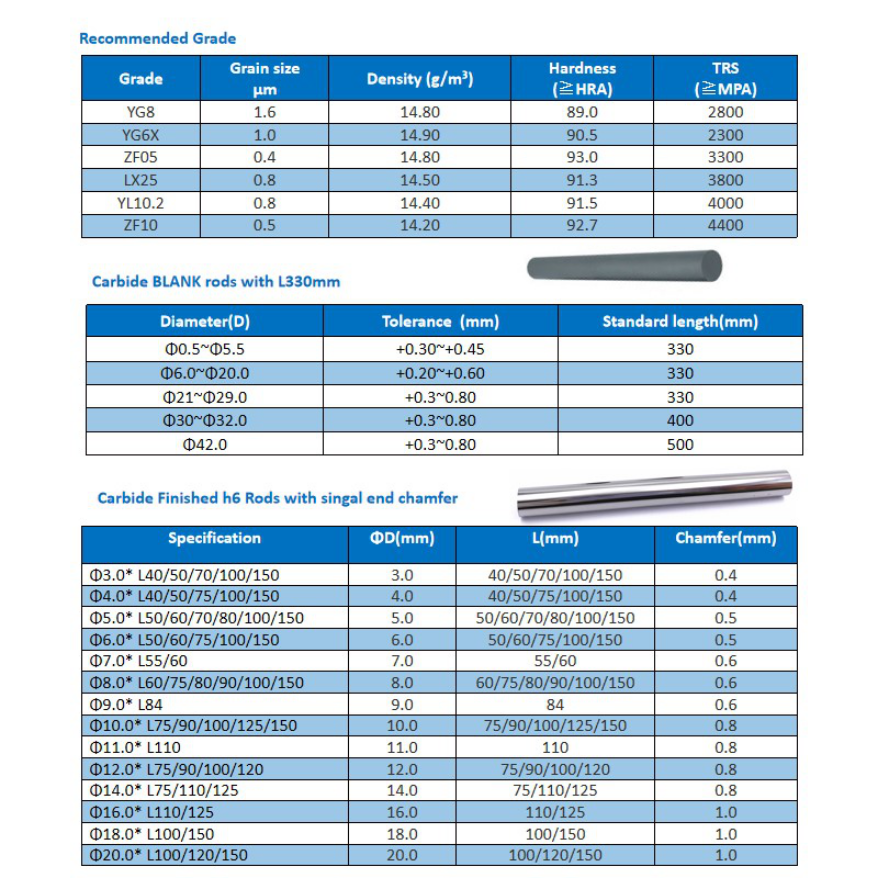

Tungsten Carbide Grade Information

|

|

|

|

|

||||

|

Grade

|

Density g/cm3

|

Hardness HRA(hv)

|

T.R.S

(M Pa)

|

Performances &applications recommended

|

||||

|

YG6

|

14.9

|

89.5

|

2150

|

Good Wear resistance, used for hard wood,processing original wood,aluminum section bar,brass rod and cast iron.

|

||||

|

YG8

|

14.6

|

89

|

2320

|

Suitable for the roughening of cast iron and light alloys and also for the milling of cast iron and low-alloy steel.

|

||||

|

YG11

|

14.4

|

87.5

|

2260

|

Medium grain, for wear parts and mining tools

|

||||

|

YG15

|

14.1

|

86.5

|

2400

|

Medium grain, for mining tools, cold heading and punching dies

|

||||

|

YS2T

|

14.45

|

92.5

|

2800

|

Fine carbide,high wear resistance,high bending strength,high resistance to bonding, high thermal strength.Machining of refractory alloys, stainless steel and high manganese steel etc.Mainly used for disc cutter and other tools

|

||||

|

YL10.2

|

14.5

|

92.5

|

3400

|

Wear resistance and strength comparatively higher,suitable for processing cast iron, non-ferrous metal and non-metalloid materials.

|

||||

|

YNi8

|

14.6

|

88.5

|

1710

|

This grade with 8% nickel binder, it has good wear resistance& corrosion resistance performance ,especially used for high pressure environmental , also good for cutting the titanium alloy.

|

||||

Related Tools

Our Main products include : Carbide Screwed Boring Bar, Plates, Rods, Sticks, Bushings, TP nozzles, 3D Printer Nozzles, Saw Blades, End Mills & Drill Bits, CNC inserts, Value Seats, Rotary Burrs, wheel cutters, Grits, Customized cutter woodworking tool,V-cutter, Shoes cutter ects. Any kinds of customized carbide products can be made.

Hot Searches