NaN / 0

Automatic Engine Oil Production Filling Machine Line Bottling Machine Oil

Get Latest Price

US$ 18000

≥1 Sets

US$ 16000

≥5 Sets

US$ 12000

≥10 Sets

Quick Details

Machinery Capacity:

4000BPH, 6000BPH, 2000BPH

Packaging Material:

Wood

Filling Material:

Oil

Filling Accuracy:

0.1%

Product Details

AUTOMATIC Engine Oil FILLING MACHINE

The NP-VF automatic engine oil filling machine is designed and manufacturer by shanghai Npack,The equipment is a special filling equipment for oil packaging. The special filling system is used: servo motor driven filling system. The filling machine has the characteristics of fast filling speed, high precision and no dripping. It can be equipped with different straight-line-filling heads according to the requirement of

clients,which meets the requirement of GMP. It is especially suitable for oil packaging enterprises with medium and high production capacity.

1.The filling machine can be equipped with high-speed capping machine, oil barrel labeling, oil capping machine,oil bottle inkjet printer, oil bottle automatic packing and palletizing machine. The oil filling and packaging line is formed. High efficiency, energy saving and automation equipment.

2.the capcity of the line is range from 800b/hour to 5000bottles per hour

3.the filling volumeof the machine is range from 100ml to 5000ml

2.the capcity of the line is range from 800b/hour to 5000bottles per hour

3.the filling volumeof the machine is range from 100ml to 5000ml

|

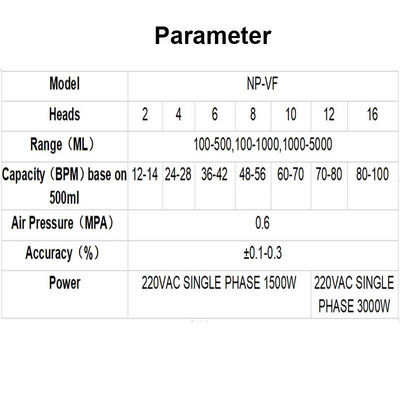

Model

|

NP-VF-2

|

NP-VF-4

|

NP-VF-6

|

NP-VF-8

|

NP-VF-10

|

NP-VF-12

|

NP-VF-16

|

||||||

|

Heads

|

2

|

4

|

6

|

8

|

10

|

12

|

16

|

||||||

|

Range

|

100-500ml,100-1000ml,1000-5000ml

|

|

|

|

|

|

|

||||||

|

Capacity

for 500ml |

12-14 bpm

|

24-28 bpm

|

36-42 bpm

|

48-56 bpm

|

60-70 bpm

|

70-80 bpm

|

80-100 bpm

|

||||||

|

Air Pressure

|

0.6Mpa

|

|

|

|

|

|

|

||||||

|

Accuracy

|

±0.1-0.3%

|

|

|

|

|

|

|

||||||

|

Power

|

220VAC single phrase 1500W

|

|

|

|

|

220VAC single phrase 3000W

|

|

||||||

Main Features(Filling machine)

1. Controlled by servo system.Adjustable filling speed.Intergrated digital control with Schneider PLC and high tech touch screen

controls for easy operation.

2. Designed for easy changeover and cleaning.

3. Professional manufacturing techniques using the ISO-9001 system.

4. 304 or 316L stainless steel.

5. Digital control system to enable multiple filling actions on the same bottle for double,triple and more.

controls for easy operation.

2. Designed for easy changeover and cleaning.

3. Professional manufacturing techniques using the ISO-9001 system.

4. 304 or 316L stainless steel.

5. Digital control system to enable multiple filling actions on the same bottle for double,triple and more.

Main Features(Capping Machine)

1. Power height adjustment.Comprehensive universal cap chute and escapement.

2. Hand-wheel operated.

3. Gripper Belt height and width adjustment.

4. Variable speed AC motors 4,6 or 8.

5. Spindle Wheels Spindle Wheel adjustment knobs,with lock nut hand wheel.

6. No change parts required for a wide range of containers.

7. Sanitary 304 stainless steel drive shafts and adjustment support shafts.

2. Hand-wheel operated.

3. Gripper Belt height and width adjustment.

4. Variable speed AC motors 4,6 or 8.

5. Spindle Wheels Spindle Wheel adjustment knobs,with lock nut hand wheel.

6. No change parts required for a wide range of containers.

7. Sanitary 304 stainless steel drive shafts and adjustment support shafts.

Hot Searches