NaN / 0

New For BMW x6 wheels x3 x4 x5 x5m x6m x7 forged aluminium alloy wheels custom modified 20 21 22 inches

Get Latest Price

US$ 233

≥4 Pieces

US$ 202

≥100 Pieces

US$ 183

≥200 Pieces

Quick Details

Finishing:

Black

Width:

5/5.5/7/7.5/8/8.5/9/9.5/10/10.5/11/11.5/12 Inch

Place of Origin:

Guangdong, China

Brand Name:

XieHe, XieHe

Product Details

|

MODEL

|

XH-B018-1

|

XH-B018-2

|

|

|

Material

|

Alloy,Aluminum 6061-T6,magnesium alloy,Customized

|

|

|

|

SIZE(INCH)

|

Customizable

|

|

|

|

PCD(MM)

|

5*120

|

5*114.3

|

|

|

ET(MM)

|

28/Customized

|

30/Customized

|

|

|

CB(MM)

|

64.1/Customized

|

64.1/Customized

|

|

|

Load(KG)

|

850

|

900

|

|

|

Weight(KG)

|

12

|

13.1

|

|

|

Color

|

Matte/Bright Black,Silver,Ash grey,Gold Customizable

|

|

|

|

Advantage

|

Strong, lightweight, good heat dissipation, good handling performance

|

|

|

|

Warranty

|

36 Months

|

|

|

|

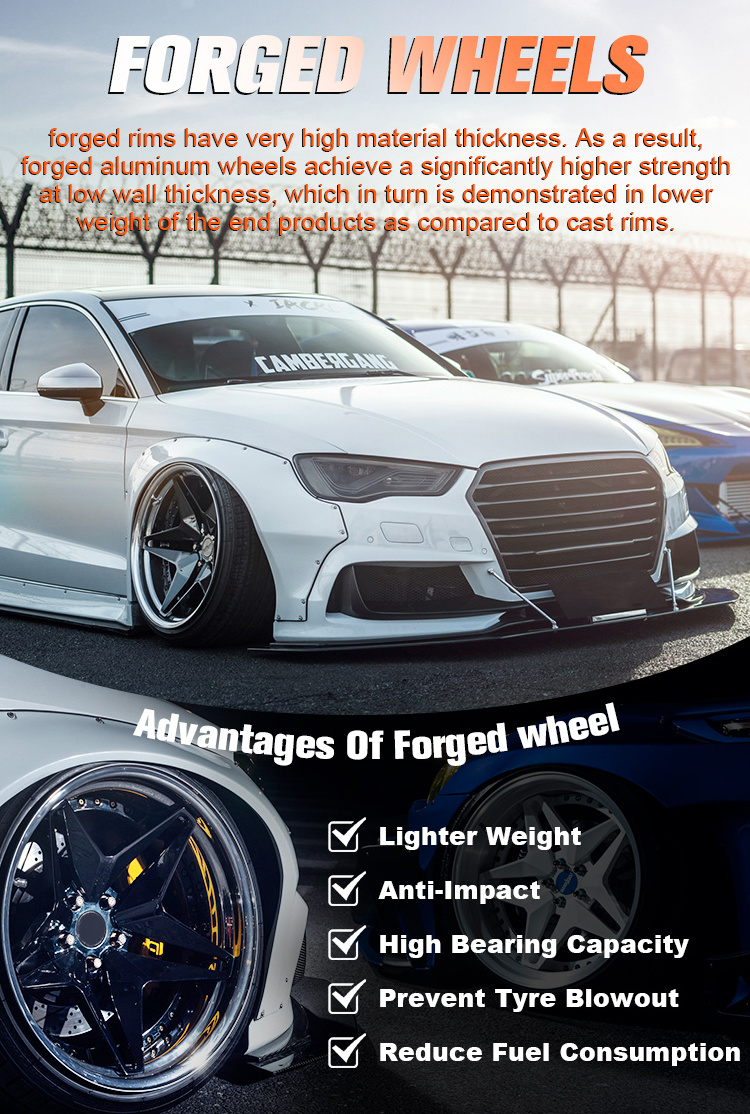

Advantages Of Forged Wheels

|

|

|

||

|

Forged wheels

|

VS

|

Cast wheels

|

||

|

Forged wheels are based on vehicle weight and Safety performance level for wheel structure design higher security

|

Security

|

Cast wheels are mass production driving safety low grade

|

||

|

Forged wheels except for pitch/offset/center hole/ general data such as J value exclusive design for special car .

Also according to brake calipers size to adjust the spoke arc

|

Suitability

|

Cast wheels are not private car does not meet data does not match

|

||

|

Aviation aluminum T6061 high manufacturing cost high density impact resistance strong ability

|

Material

|

Ordinary aluminum melts,low manufacturing cost, density difference, easy to deform and crack

|

||

|

Through the 10,000-ton forging process, the molecular structure of the wheel is tighter,the rigidity is stronger,and the weight is lighter

|

Lightweight

|

Cast wheels are liquid die casting ,craftsmanship relatively simple

|

||

Facts&Figures:

1. Premium design rims

2. Extremely Sophisticated manufactruing process

3. Top quality base material 6061-T6(used in aviation industry)

4. Weight reduction approx. 30% due to higher material density.

5. Thinner spokes achieved by recessed spokes

6. Stronger gloss effect due to a silicon amount of just 0.8%

7. Highest quality ceramic polish with double clearcoat.

FAQ

Q1.Why choose you?

A1 As a gold supplier ,we have a good reputation on our customers,because of the good quality ,suitable price and good service.

Q2.You are factory or trading company?

A2 We are m

ultispecialty

supplier, we also do trading online.

Q3.What is your shipping way?

A3 We usually ship it via DHL UPS Fedex TNT. lf you have big quantity, you can choose air freight or Sea shipment.

Q4.What is your payment?

A4 TT wire bank transfer,LC for Mass order . Trade assurance pay on Alibaba for sample.

Q5.Can l take a sample for quality check ?

A5 Sure, we offer free sample for some low cost OEM products, but clients pay shipping cost.

Q6.Can you put my brand name(LOGO)on the products?

A6 Yes,We can.MOQ 4pcs each model.

Q7.Can you printed our logo on the product or do the customized package box for us

?

A7 Sure, our factory produces OEM ODM .

Q8.How can you slove the problem if we receive the defective goods?

A8 Send us the pictures or video first time, we will send free replacement spare parts for you.