NaN / 0

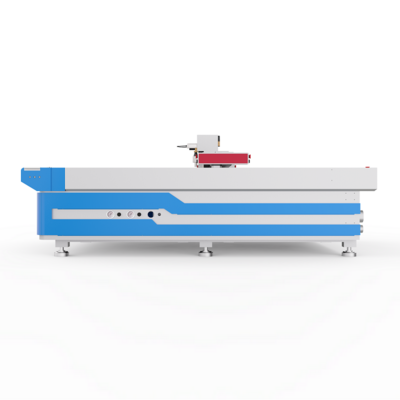

Fully Automated Table Cloth Automatic Fabric End Cutting Machine Electric Round Knife Fabric Cloth End Edge Cutter Machine

Get Latest Price

US$ 9500

≥1 Sets

US$ 8500

≥5 Sets

Quick Details

Production Capacity:

100-1400mm/s

Voltage:

220V/380V

Application:

Fabric Leather Paper Board Flatbed PVC Foam Board, corrugated/honeycomb cardboard,kT board,sticker,PP paper etc.

Place of Origin:

Henan, China

Product Details

Product Overview

Fully Automated Table Cloth Automatic Fabric End Cutting Machine Electric Round Knife Fabric Cloth End Edge Cutter Machine

Fabric End Cutting Machine Cloth Cutter Machine PET Film Cutting Plotter

Applicable industry

1. The platform detection device regulates the knife pressure automatically, enabling a level platform and perfect cutting.

2. The high precision CNC oscillating knife leather cutting machine can induce draft separately and easily cuts small pieces.

3. The anti-collision and the built-in auto-sensing devices ensure the security of oscillating knife leather cutting machine.

4. High efficiency can be realized without making a high-cost knife model.

5. Equipped with plotting pen, oscillating cutting tool, creasing tool, and drag knife tool to meet customers' different requirements. can save on costs while maintaining speed and accuracy.

Applicable materials:

It can cut on fabric, leather, cardboard, plastic, paper, rubber, EVA foam, and it can cut many types of foam, such as closed cell foam, rubber foam, foamex, foam core, KT board, EPE foam, polyethylene foam, PE foam, PVC foam, etc. It's widely used for packaging protection, advertising display, termal insulation, model & mock up making, puzzle and pattern cutting, etc.

PRODUCT SPECIFICATIONS

|

Model

|

NDL-L1313 Oscillating Knife Cutting Machine

|

|

Cutting size

|

1300*1300mm

|

|

Tools

|

Oscillating cutting tool

Hobbing cutter, millin knife, creasing wheel, punching tool. (optional)

|

|

Cutting speed

|

100-1400mm/s

|

|

Cutting thickness

|

≤50mm(customized according to different materials)

|

|

Repeat precision

|

0.05mm

|

|

Motor

|

Servo motor

|

|

Power

|

10KW

|

|

Fan power

|

220V/2.2KW

|

|

Material fixing method

|

Vacuum absorption

|

|

Data format

|

DXF, HPGL, PLT etc.

|

|

Interface

|

USB/Enternet port

|

|

Safety

|

Use infrared sensing, safe and reliable

|

|

Transimission Materials

|

Combine use of screw rod, aluminum rack and imported synchronous belt to guarantee higher accuracy and durability.

|

|

Application materials

|

Carton box, paper card, cardboard, KT board, sticker, rubber, EVA, foam etc.

|

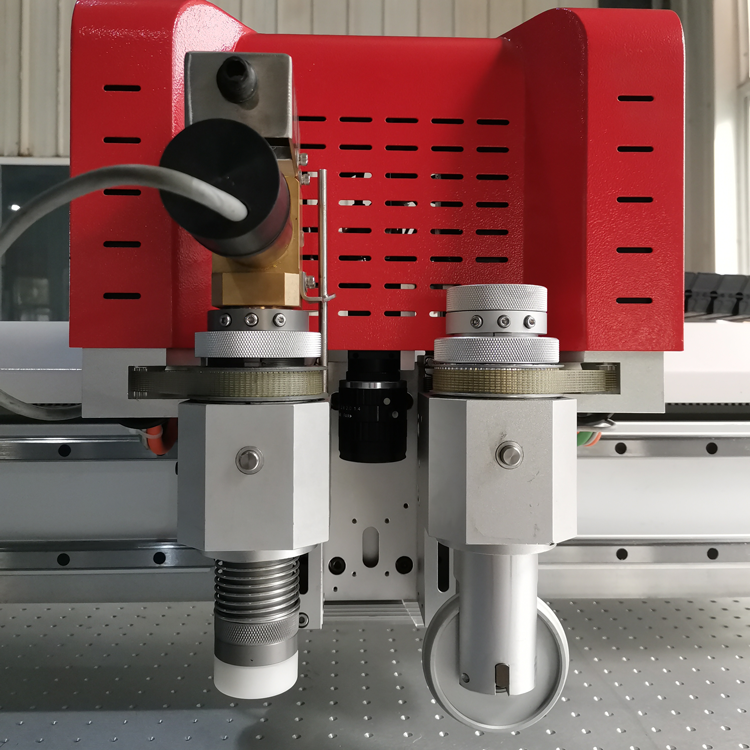

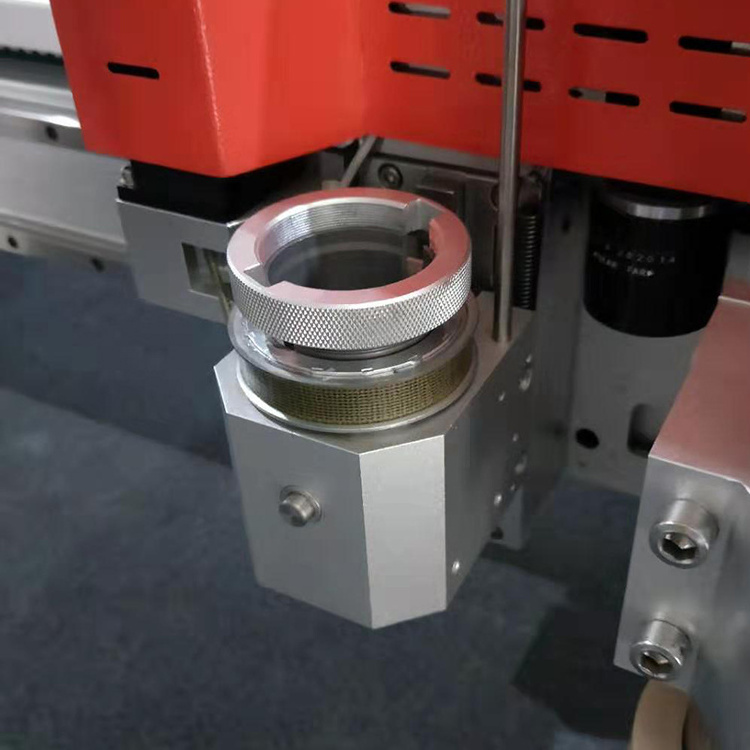

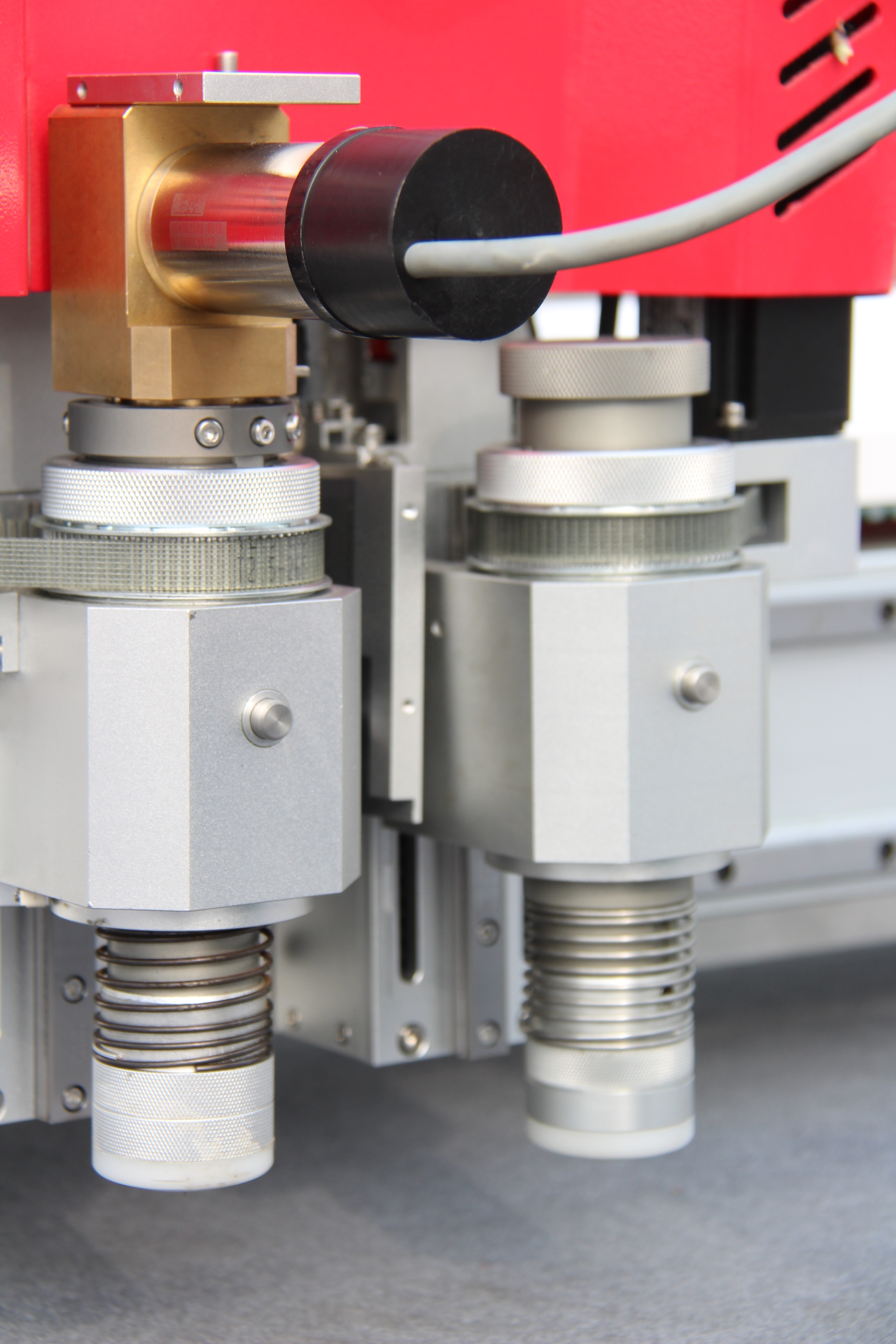

Tools and Function

1. Oscillating knife:

For common material cutting,it is fast, accurate and stable, can finish difficult with smooth lines

2. Creasing wheel:

A set of creasing wheel with four different sizes can make good folding lines according to your different materials.

3. 45 degree cutting knife:

This is special for V groove making when it comes to materials like honeycomb board, gray board and other relatively thicker

materials.

4. Milling knife: This is specialized for Acrylic and thin wood material cutting.

5.CCD: camera, professional for positioning for print materials. Automatic and precise.

For common material cutting,it is fast, accurate and stable, can finish difficult with smooth lines

2. Creasing wheel:

A set of creasing wheel with four different sizes can make good folding lines according to your different materials.

3. 45 degree cutting knife:

This is special for V groove making when it comes to materials like honeycomb board, gray board and other relatively thicker

materials.

4. Milling knife: This is specialized for Acrylic and thin wood material cutting.

5.CCD: camera, professional for positioning for print materials. Automatic and precise.

Applications

Our Advantages

Packing&Shipping

Why Choose Us

FAQ

1. Q: Are you Factory or Trading company?

A: We are a factory and the first manufacturer of vibrating knife cutting machines in North of

China with about 10 years experiences in this field.

2. Q: Can you customize the machine according to my needs?

A: Yes, we accept the customized machine, our company has an experienced professional

design team, we can give you our professional suggestions according to your requirements

and design a cost-effective machine for your needs.

3. Q: What is the difference between your product and the laser cutting machine?

A: a. Our products are cut with vibrating blades, no laser, no pollution, and create a good

working environment for workers.

b. Blade cutting can ensure the edge of material cutting smooth without burning.

4. Q: Is your price have a discount for dealers?

A: Yes, we have a favorable policies for dealers. Please tell us your order quantity or annual

purchase quantity. The price will be adjusted according to the order quantity. For details,

please consult our sales staff.

5. Q: How is your after-sales policies?

A: a. The machine warranty is 3 years after shipment date. During the warranty period,

the main accessories(except the wearing parts) are replaced free of charge under the normal operation. Otherswise, under improper operation need to pay.

b.We have an experienced after-sales team 24h online service and a complet after-sale system. Factory training support, Video technical support, online support, Engineers available to service machinery overseas if needed.

c. Inquiries are typically answered within 24 hours.

6. Q: Can you provide ODM and OEM services?

A: Yes, our R&D team with an average of 10 years experiences, the ODM&OEM service are

satisfied with our customers.

A: We are a factory and the first manufacturer of vibrating knife cutting machines in North of

China with about 10 years experiences in this field.

2. Q: Can you customize the machine according to my needs?

A: Yes, we accept the customized machine, our company has an experienced professional

design team, we can give you our professional suggestions according to your requirements

and design a cost-effective machine for your needs.

3. Q: What is the difference between your product and the laser cutting machine?

A: a. Our products are cut with vibrating blades, no laser, no pollution, and create a good

working environment for workers.

b. Blade cutting can ensure the edge of material cutting smooth without burning.

4. Q: Is your price have a discount for dealers?

A: Yes, we have a favorable policies for dealers. Please tell us your order quantity or annual

purchase quantity. The price will be adjusted according to the order quantity. For details,

please consult our sales staff.

5. Q: How is your after-sales policies?

A: a. The machine warranty is 3 years after shipment date. During the warranty period,

the main accessories(except the wearing parts) are replaced free of charge under the normal operation. Otherswise, under improper operation need to pay.

b.We have an experienced after-sales team 24h online service and a complet after-sale system. Factory training support, Video technical support, online support, Engineers available to service machinery overseas if needed.

c. Inquiries are typically answered within 24 hours.

6. Q: Can you provide ODM and OEM services?

A: Yes, our R&D team with an average of 10 years experiences, the ODM&OEM service are

satisfied with our customers.

Hot Searches