|

|

Model

|

|

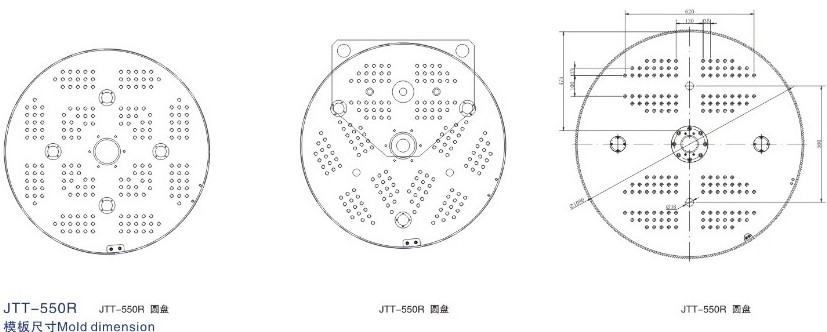

JTT-550R

|

|

Injection system

|

Screw Diameter

|

mm

|

40

|

|

|

Injection Pressure

|

kg/cm2

|

1260

|

|

|

Theoretical Shot Volume

|

cm3

|

170

|

|

|

Injection Rate

|

cm3/sec

|

113

|

|

|

Screw Stroke

|

mm

|

140

|

|

|

Screw Speed

|

rpm

|

150

|

|

|

Heating Capacity

|

kw

|

5.3

|

|

Clamping system

|

Clamping Force

|

tons

|

55

|

|

|

Opening Force

|

tons

|

8.9

|

|

|

Min Mold Height

|

mm

|

200

|

|

|

Opening Stroke

|

mm

|

200

|

|

|

Max Open Daylight

|

mm

|

400

|

|

|

Mold Dimension

|

mm

|

370*450

|

|

|

Rotary Table Diameter

|

|

1080

|

|

|

Ejector Force

|

tons

|

1.8

|

|

|

Ejector Stroke

|

mm

|

60

|

|

Other

|

Motor Power

|

kw

|

7.5

|

|

|

Sliding Table Stroke

|

mm

|

—

|

|

|

Machine Dimension

|

m

|

2.6*1.8*2.85

|

|

|

Machine Weight

|

tons

|

3

|

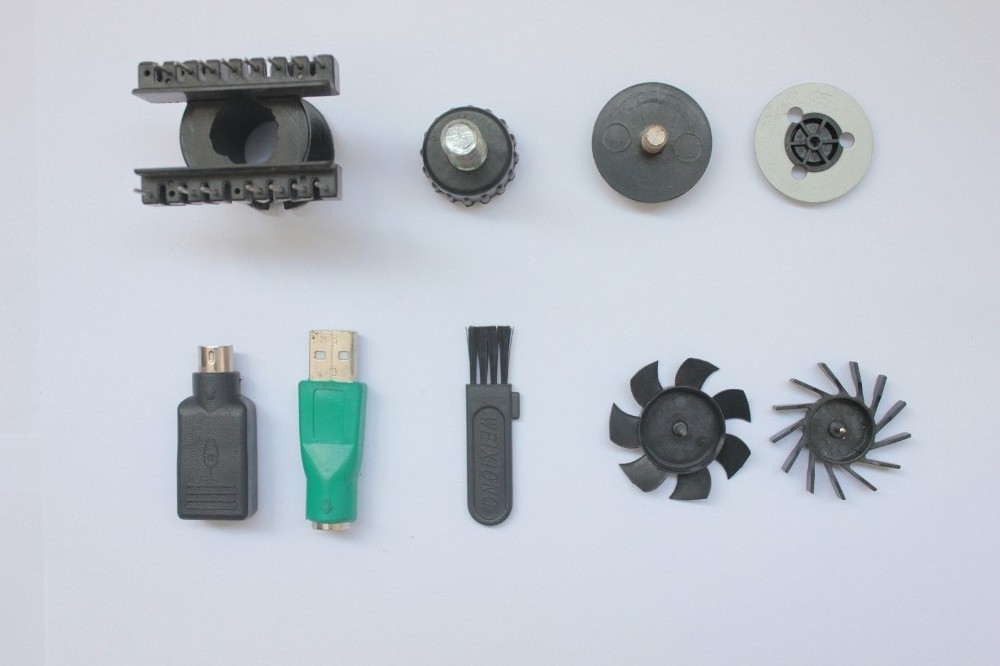

1) vertical clamping, vertical injection,

2) clamping force, injection weight and shot speed can be changed according to actual demand.

3) 2 stations, 3 stations , multi-station(one up die, two or four down die), easy for operate insert parts, improve productivity

PRODUCT ADVANTAGE

Energy-saving: save 30% energy compared to similar products by using SIFU pump system

High efficiency: SIFU motor have max speed 2200/min to increase oil pump output and improve more than 15% productivity speed

Low heating: save 55% cooling water quantity at least compared to similar products

Low noise: optimize motor working condition with imported bearing and oil pump to reduce 15-20db working noise

Precision: use completely close-cycle control with pressure sensor and motor rotary encoder to improve product consistency

SERVICE ADVANTAGE

17 years of customer service experience and summarizing customer feedback, Jintong develop a systematic and standardized service process, and also establish 24 hour response mechanism to wensure timely solve customers problems and offer perfect service to customers as soon as possible.

91.8% Response Rate

91.8% Response Rate

91.8% Response Rate