NaN / 0

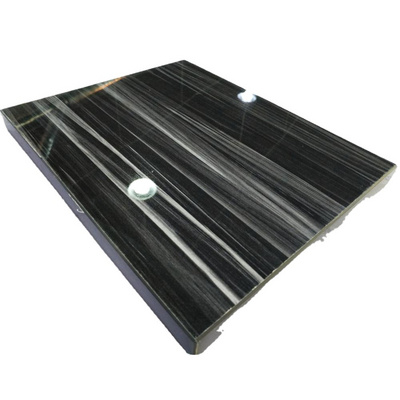

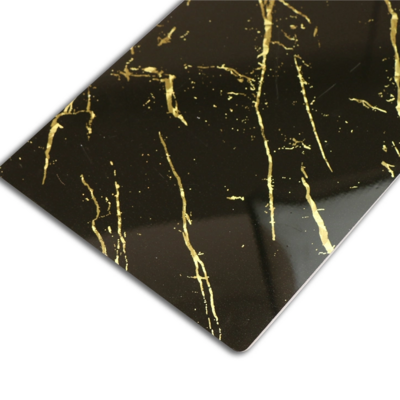

UV melamine MDF for kitchen cabinet 18mm High Gloss MDF Board

Get Latest Price

US$ 2.5

≥1000 Pieces

US$ 2.3

≥10000 Pieces

Quick Details

Project Solution Capability:

graphic design, Cross Categories Consolidation

Application:

Villa

Material:

Wood Fiber

Formaldehyde Emission Standards:

E1

Product Details

Product Description

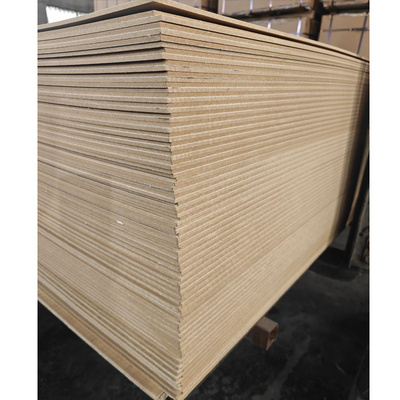

Product :plain MDF/raw MDF/MDF board

Size: 1220*2440*2-30mm

Material: poplar,hardwood

Density :680-780kg/m3

Moisture content: 4%-13%

Main market: Middle East,Asia,Africa.

Type: Standard mdf, HDF, Waterproof MDF, Fireproof MDF, Black MDF

We have different density MDF, for different use. such as 800-850kg/m3,780-760kg/m3, 700-720kg/m3, 680-700kg/m3, 600-630kg/m3 for furniture back,

|

No. |

Test Items |

Technical Specification |

Unite |

Test Result

|

|

1 |

Moisture Content |

4~13 |

% |

5.8 |

|

2 |

Density |

450~880 |

Kg/m3 |

730 |

|

3 |

Density Tolerance |

±7.0 |

% |

±1.4 |

|

4 |

Expansion ration in thickness due to water absorption |

≤10 |

% |

8.8 |

|

5 |

Internal bonding |

≥0.45 |

Mpa |

0.49 |

|

6 |

Modulus of rupture |

≥20 |

Mpa |

26.8 |

|

7 |

Modulus of elasticity |

≥2200 |

Mpa |

3280 |

|

8 |

Screw holding |

Face≥1000 |

N |

1120 |

|

Side≥800 |

870 |

|||

|

9 |

Surface bonding |

|

Mpa |

1.28 |

|

10 |

Formal Dehyde Emission |

E1: ≤9.0 |

mg/100g |

4.9 |

|

E2: ≤30.0 |

20 |

MDF colour and material :

100% poplar material with white colour

100% pine material with light yellow colour ,

70% poplar or 70% pine mix 30% hard wood with normal colour

Packing:

The bottom is strong pallets with one sheet of protected board which is MDF or Particle board and thickness is not less than 15mm. All the goods are wrapped by plastic bags avoiding any moisture. The top and four sides with one sheet of protected board which is not less than 4mm MDF or 8mm Particle board . Then all the goods are strengthened by steel strips. The details as the following pictures

Advantage

1.Uniform plate density, excellent physics performance; It's close to natural wood but better than natural plank.

2.High strength and good dimensional stability, thickness is2.5mm-30mm,it has been widely used.

3.Good mechanical processing performance, It may use natural wood processing equipment and methods for machining.

4.Flat surface,so It is easy for secondary processing.

Green HMR Waterproof MDF :

Red Color Fireproof /Fire Retardant MDF:

Black Core High Waterproof/Fireproof MDF:

Hot Searches