NaN / 0

CX2020A induction brazing machine induction electrical heating equipment

Get Latest Price

US$ 500

≥1 Sets

Quick Details

Place of Origin:

Sichuan, China

Brand Name:

JKZ

Voltage:

AC220V 50-60hz, AC220V 50-60hz

Dimension(L*W*H):

660*300*500mm

Product Details

Product Description

Induction Electrical Heating Equipment

Application Range:

1. Heating treatment of metal: hardening,tempering,annealing,and normalizing

2. Heating before deformation: forging, swaging, upsetting, bending, and piercing.

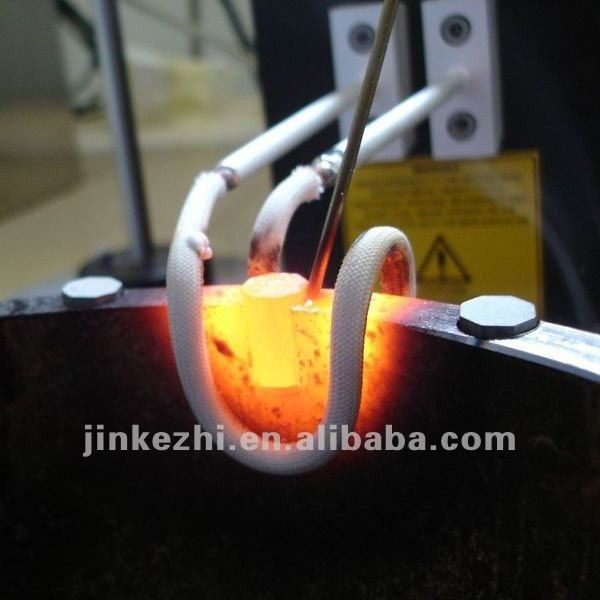

3. Braze welding and Soldering: brazing of steel, brass, and copper to each other, and brazing of metal tube, alloy cutter , carbide saw blade, pipe joints, etc.

4. Shrink fittings in any manufacturing process, for example, shrink fittings of motor rotors to shafts, shrink fitting of shell casings of compressors.

5. Coating: dissimilar metal, before insulation and curing, such as paint.

6. Melting: all kinds of metal,like ferrous metal, non-ferrous metal and noble metal.

7. Other applications including crystal growing, cap sealing, sintering, carbon vapor deposition,levitation,exit axial deposition,and generation of plasma.

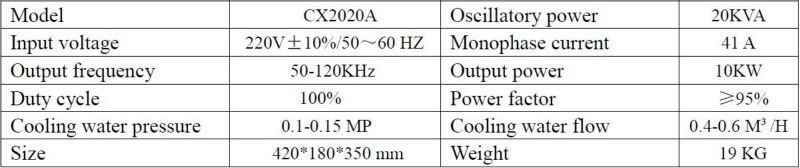

Parameters table

Related Products

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

Our Company

Chengdu Jinkezhi Electronic Co., Ltd., known as JKZ induction, is a scientific and technological enterprise; Established in the year 1993, with 25 years rich experience of producing induction heating machines of high frequency, supersonic frequency and medium frequency. products are widely used in welding, brazing, hot forging, heat treatment, melting.

Professional R & D team And designing team, famous technical experts of rich induction heating knowledge, Every product own intellectual property right. These make us the one of leader of advanced induction heating technology in China.

Professional R & D team And designing team, famous technical experts of rich induction heating knowledge, Every product own intellectual property right. These make us the one of leader of advanced induction heating technology in China.

Manufacturing Technique

Certifications

Packing & Delivery

|

Packaging

|

|

|

|

Size

|

660*300*500mm

|

|

|

Weight

|

23kgs

|

|

|

Packaging Details

|

induction pipe heater packing material is plywood box, suitable for export.

|

|

FAQ

Q1, Do you need the packing machines for premade bags or bags from roll of film?

For roll film we advise VFFS packing machines VP420, VP500, VP620, VP800, VPL1000 and VPL1200. For

premade bags we advise doypack machine working on bags with or without ziplock

Q2, What products do you pack, solid, granule, flake, powder or liquid?

For liquid we advise piston or motor pump, for powders we advise auger filler or volumetric cup filler, for solid,

flake and granules we advise multihead weigher, linear weigher or volumetric cup filler.

Q3, What are the bag sizes and target weight in each pack?

For VFFS packing machine the minimum film width we work on is 120mm, the maximum film width we work

on is 1200mm.

For doypack machine the bag width working on is minimum 70mm and maximum bag width 4550mm.

Q4, Does your company work on OEM?

Yes, we have a professional design and technical team to do the customization

Q5, What’s the delivery time after the order is placed?

We arrange the shipment in 30-35days for standard machine. It takes us more days for customized machines

Q6, How about the warranty?

The warranty is one year and we provide lifelong maintenance.

Q7, What can you provide after service?

We provide machine running video, instruction manual in English, spare parts and tools for installation. Also

our engineers are available to clients’ factory and technical training.

Hot Searches