NaN / 0

Industrial tomato and garlic onion sauce or jam making machine processing production line

Get Latest Price

US$ 78000

≥1 Sets

US$ 76000

≥2 Sets

US$ 44000

≥3 Sets

Quick Details

Machinery Capacity:

Customized

Brand Name:

EasyReal

Year:

New and Unused

Dimension(L*W*H):

Based on specific machines

Product Details

Product Description

RAW MATERIAL:

| • Fresh Onion |

| • Fresh Garlic |

| • Fresh Chili |

| • Fresh Tomato |

| • Pulp or Paste of Onion or Garlic or Chili or Tomato |

END PRODUCTS:

| • Jam, Sauce and Ketchup |

END PRODUCT PACKAGES:

| • Aseptic Bag |

| • Tin Can |

| • Glass Bottle |

| • Pet Bottle |

| • S achet |

| • Pouchsachet |

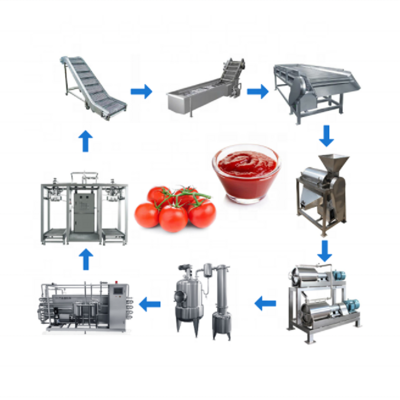

( The Flo wchart O f Onion and Garlic and Chili and Tomato Ja m, Sauce and ke tchup )

Industrial fruit vegetable tomato and garlic onion sauce or jam making machine processing production line

DESCRIPTION:

The

Multifuntional

Onion and Garlic and Chili and Tomato

Ja

m, Sauce and ke

tchup

processing line is combining Italian technology and conforming to Euro-standard. Due to our continuous development and integration with international companies like STEPHAN Germany, OMVE Netherlands, Rossi & Catelli Italy, etc, Easyreal Tech. has formed its unique and beneficial characters in design and process technology. Thanks to our much experience over 100 whole lines, Easyreal TECH. can offer production lines with different capacity according to your actual requirment and customizations including plant construction, equipment manufacturing, installation, commissioning and production.

Complete line for Onion and Garlic and Chili and tomato processing, to obtain Jam, Sauce and ketchup, drinkable juice. We design, manufacture and supply complete processing line including:

---

---

Onion end cutting and Garlic separating.

------ Crushing and pulping and refinning of Onion and Garlic.

--- --- Dilution and Blending tanks–-The tanks are always desiged with three-jacket layers. It has the function of heating. It is equipped with liquid lavel sensor and temperature sensor. Fully automatic control with liquid level ogf the tank and temperature.

------Colloid Grinder.

---

---

Vacuume deaerating, completely controlled by PLC.

---

---

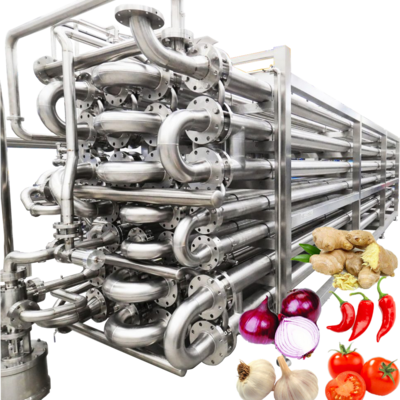

Tube in Tube Sterilizer specifically designed for high viscous products, completely controlled by PLC.

---

---

Filling system. We can supply different type fillin system. It always depend on your actual requirment and the type of package.

---

---

CIP system.

The Jam, ketchup, sauce, tomato juice in tin can, bottle, pouch, etc. can be produced from pulp or paste in aseptic drum. Or directly produce end product (Jam, ketchup, sauce, juice in tin can, bottle, pouch, etc.) from fresh Onion, Garlic, Chili or tomato.

Application:

Easyreal TECH. can offer complete production lines with daily capacity from 2 tons to 1500tons and customizations including plant construction, equipment manufacturing, installation, commissioning and production.

FEATURES:

1.Main structure is SUS 304 and SUS316L stainless steel.

2.Combined Italian technology and conform to Euro-standard.

3.Special design for saving energy (energy recovery) to increase the energy utilization and greatly reduce production cost.

4.This line can handle similar fruits with similar characteristics, like: Chili, apricot and peache, etc.

5.Semi-automatic and fully automatic system available for choice.

6.The end product quality is excellent.

7.High productivity, flexible production, the line can be customized depend on actual need from customers.

8.Low-temperature vacuum evaporation greatly reduces the flavor substances and nutrient losses.

9.Fully automatic PLC control fro choice to reduce the labor intensity and improve production efficiency.

10.Independent Siemens or Omron control system to monitor each processing stage. Separate control panel, PLC and human machine interface.

Independent control system adheres to Easyreal's design philosophy:

Realization of automatic control of material delivery and signal conversion.

1.High degree of automation, minimize the number of operators on the production line.

2.All electrical components are international first-class top brands, to ensure the stability and reliability of equipment operation;

3.In the process of production, man-machine interface operation is adopted. The operation and state of the equipment are completed and displayed on the touch screen.

4.The equipment adopts linkage control to automatically and intelligently respond to possible emergencies.

Suppliers and brands of components ofcontrol system:

Core and key electrical components are selected from international first-class brands, such as ABB button from Switzerland, Germany Siemens touch screen and PLC, Ddanmark DANFOSS frequency inverter, France SCHNEIDER low-voltage apparatus .

Supplier Brand

Maybe you need more...

| Other product lines | Pre-processing equipment | Beverage production line | Laboratory production line |

Product Application

Hot Searches