NaN / 0

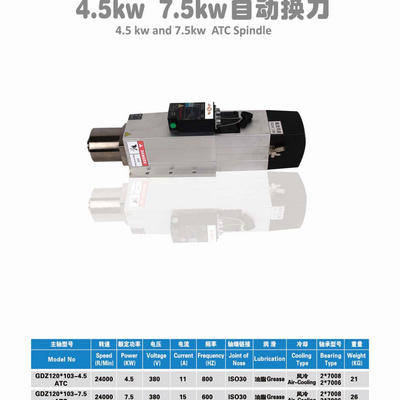

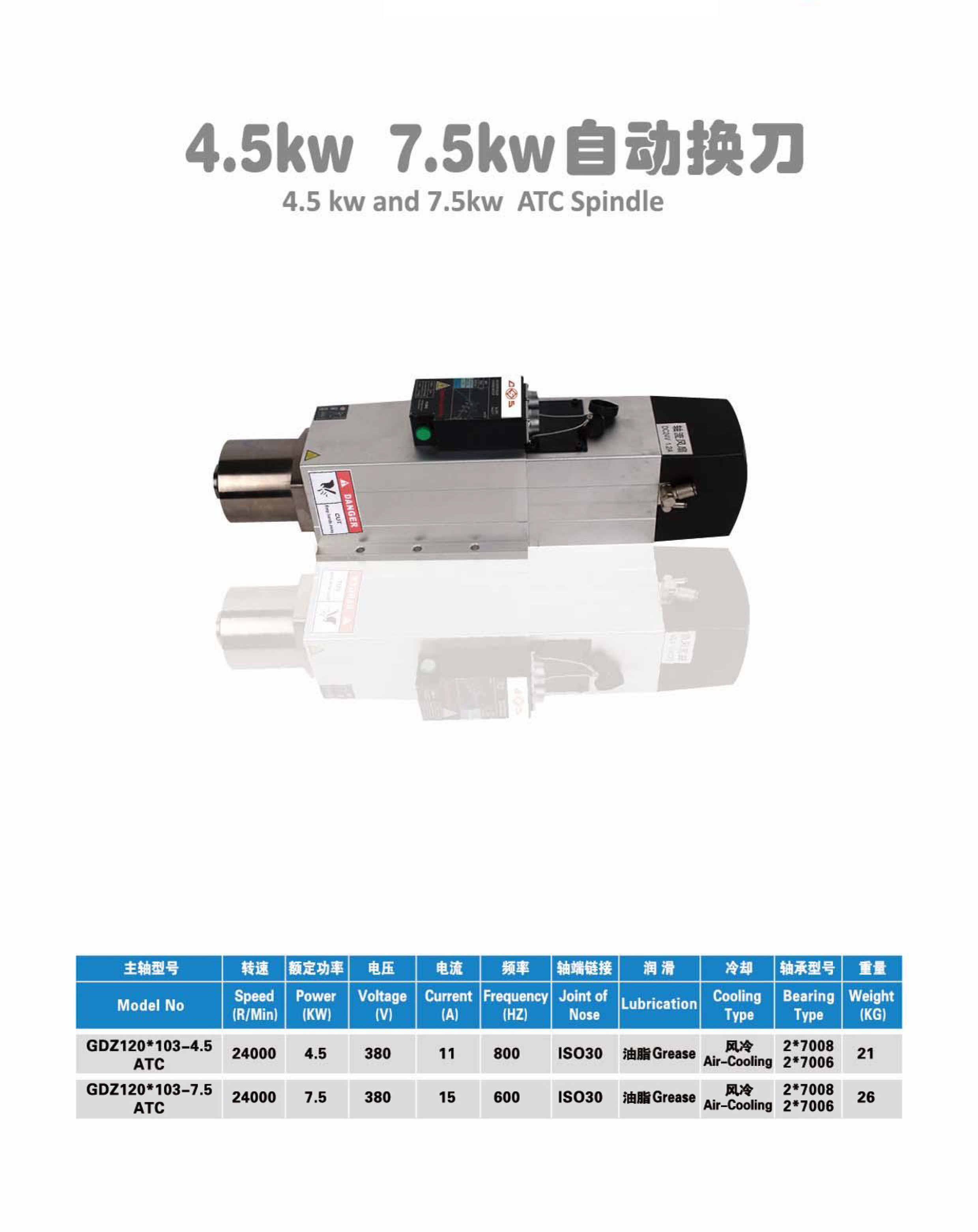

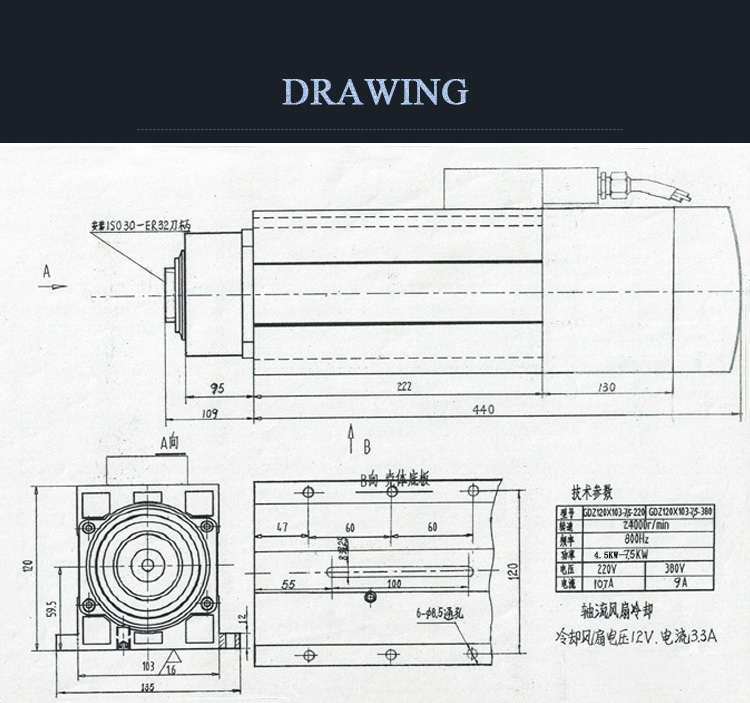

cnc spindle motor air cooled 4.5-7.5kw ATC spindle for cnc router

Get Latest Price

US$ 1175

≥1 Pieces

US$ 1125

≥5 Pieces

US$ 1075

≥10 Pieces

US$ 800

≥50 Pieces

Quick Details

Place of Origin:

Zhejiang, China

Weight (KG):

24

Maximum Torque:

demand

Operating Speed:

24000r/min

Product Details

Product Description

1. The electric spindle and the frequency inverter shall be suitable with each other. The specifications and parameter settings of

the inverter shall match the nominal parameters of the spindle, and it will burn the spindle if the settings are notcorrect.

2. Before using water-cooling spindle, it shall ensure that cooling cycle system works normally and the running underno cooling

conditions is prohibited. The volume of cooling water is calculated as per 1 liter/kw, minute, the minimum flow ofcooling water is

not less than 5 liter/minute, cooling water pipe and the nozzle shall be connected reliably and there is noleakage.

3. The cooling liquid shall be clean and free of grease and the temperature shall be within 5-30C. The cooling medium shall carry

out force cooling when the ambient temperature is higher than 30"C. The precision lathe requires the coolingliquid with a constant

temperature of 20t2'C.

4. During storage and transport of the spindle, the status of highspeed grease inside the bearing will change. The user shall run

it at a low speed first by starting from the lowest speed of the spindle for 30 minutes and then 20 minutes for every 3000 rounds;

otherwise there will have abnormal sound, noise, heat and other phenomena, which will affect the bearing lifeif the spindle is

started directly at a high speed. During long term storage, the spindle shall run (at Iow speed) for 15~30minutes once a week at

least.

the inverter shall match the nominal parameters of the spindle, and it will burn the spindle if the settings are notcorrect.

2. Before using water-cooling spindle, it shall ensure that cooling cycle system works normally and the running underno cooling

conditions is prohibited. The volume of cooling water is calculated as per 1 liter/kw, minute, the minimum flow ofcooling water is

not less than 5 liter/minute, cooling water pipe and the nozzle shall be connected reliably and there is noleakage.

3. The cooling liquid shall be clean and free of grease and the temperature shall be within 5-30C. The cooling medium shall carry

out force cooling when the ambient temperature is higher than 30"C. The precision lathe requires the coolingliquid with a constant

temperature of 20t2'C.

4. During storage and transport of the spindle, the status of highspeed grease inside the bearing will change. The user shall run

it at a low speed first by starting from the lowest speed of the spindle for 30 minutes and then 20 minutes for every 3000 rounds;

otherwise there will have abnormal sound, noise, heat and other phenomena, which will affect the bearing lifeif the spindle is

started directly at a high speed. During long term storage, the spindle shall run (at Iow speed) for 15~30minutes once a week at

least.