NaN / 0

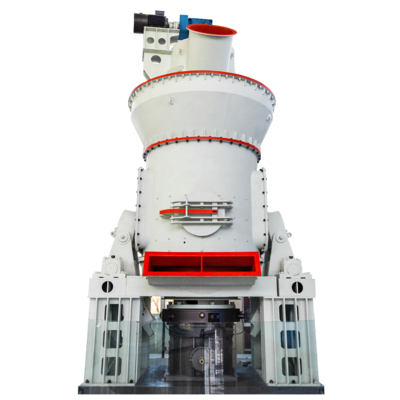

Ultrafine micron calcite grinding mill equipment, mine pulverizer superfine powder limestone coal grinder machine price

Get Latest Price

US$ 3500

≥1 Pieces

US$ 3300

≥3 Pieces

US$ 3008

≥5 Pieces

Quick Details

Output (kg/h):

500 - 1000 kg/h

Feeding Size (mm):

1 - 25 mm

Output Size (mesh):

100 - 325 mesh

Power (kW):

18.5

Product Details

Product Description

Ultrafine micron calcite grinding mill equipment, mine pulverizer superfine powder limestone coal grinder machine price

2ZM series of vibration mill is a new type of efficient grinding equipment in grinding fine and super fine powder materials.It is more convenient than conventional rotary grinding machine (efficiency of 2-5 times, reducing energy consumption by 20% - 30%). the machine has various vibration strength,high efficiency ,low power consumption, less noise and compact structure, convenient installation and maintenance,etc.the vibrating mill falls in with popular demands.

Vibrating grinding mill working principle

Drive motor moves around flexible coupling to rotate vibrator ,and then producing enough vibrating force ,then the body of the mill does periodic motion ,and to continuously transfer the force to all the materials (raw materials and medium) in the roller,the material is crushed by extruding force between medium and the grinding materials .during the process We can lower down the temperature inside the mill chamber for heat sensitive material grinding. This mill is of high performance with simple process.

Main Features

1)Low energy consumption and low production cost.

2)Easy installment and maintenance,

3)Closed milling system,

no dust emission, no pollution

4)

Simple production process

, suitable for automatic remote controlling and switching

5)

Dry milling or wet milling

are available, protective gas can be added

6)Perfect electrical control function,

very convenient

for switching system

Application field

The vibrating grinding mill can be widely used in mineral, building materials ,grinding materials of powder metallurgy ,electric, ceramic,, refractory, magnetic material, Chemical, food ,and other industries, it is the ideal substitute of ball mill.

Technical Parameter

|

VIBRATING BALL MILL

|

|

|

|

|

||||

|

Model

|

Power

|

Capacity

|

Inlet size

|

Discharge size

|

||||

|

2ZM100

|

18.5KW

|

0-1TPH

|

0-25MM

|

0.8-0.104MM

|

||||

|

2ZM200

|

22KW

|

0-2TPH

|

0-25MM

|

0.8-0.104MM

|

||||

|

2ZM400

|

37KW

|

0-4TPH

|

0-25MM

|

0.8-0.104MM

|

||||

|

2ZM600

|

55KW

|

0-8TPH

|

0-25MM

|

0.8-0.104MM

|

||||

|

2ZM1000

|

75KW

|

0-15TPH

|

0-25MM

|

0.8-0.104MM

|

||||

|

2ZM1200

|

90KW

|

0-18TPH

|

0-25MM

|

0.8-0.104MM

|

||||

|

2ZM1500

|

115KW

|

0-22TPH

|

0-25MM

|

0.8-0.104MM

|

||||

|

How to choose suitable model?

Please let us know:

1.What is your material to be grind?its size(mm)?density(g/cm3)?

2.What is the discharge material size do you want?(mm/mesh)

3.What is the capacity per hour do you need?(T/H)

|

|

|

|

|

||||

Production line

Grinding production line

1.Hopper for raw material

2.Vibrating feeder for continuously feeding

3.Vibrating mill for grinding

4.Blimp for reduce noise

5.Vibrating screen for finish products(optional)

Packing & Delivery

Related Products

Contact us

Hot Searches