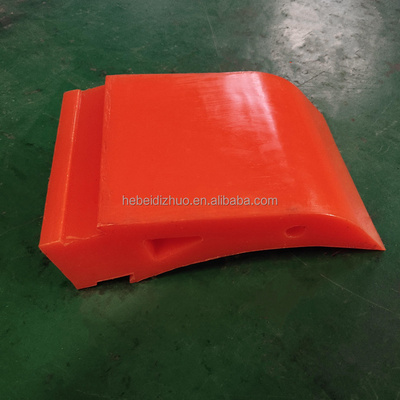

Diagonal scraper is also known as one-line sweeper.It is suitable for bidirectional conveyor belt.

|

First-class belt sweeper

|

|

|

|

|

||||

|

Hardness of cutter head

|

85-90shoreA

|

|

|

|

||||

|

Working temperature

|

40-71℃

|

|

|

|

||||

|

Adapted belt speed

|

2~6m/s

|

|

|

|

||||

|

Adapted belt width

|

200-2200mm

|

|

|

|

||||

|

The first-class belt sweeper is used at the front end of the belt roller, and the sweeper scraper at the head is mainly made of polyurethane, which mainly cleans large particles of materials. The cutter head is attached to the roller belt, which makes it easier to play the role of sweeper.

|

|

|

|

|

||||

|

Secondary belt sweeper

|

|

|

|

|

||||

|

Hardness of cutter head

|

85-90shoreA

|

|

|

|

||||

|

Working temperature

|

40-71℃

|

|

|

|

||||

|

Adapted belt speed

|

2~6m/s

|

|

|

|

||||

|

Adapted belt width

|

200-2200mm

|

|

|

|

||||

|

The second sweeper is made of polyurethane and alloy, which mainly cleans the fine adhesive materials at the stable position of the belt. These two materials are mainly selected according to the customer's working conditions. For example, the customer's belt adopts hot and cold vulcanized joints, and both of them can be selected. If it is a mechanical joint, only the scraper made of polyurethane can be selected, because the alloy cutter head is easy to scratch the belt, causing damage to the mechanical joint and increasing the maintenance cost. If the humidity in the cleaning condition is too high and the belt is a hot-cold vulcanized joint, it is recommended to use alloy sweeper, because the application effect of polyurethane sweeper is easily affected if the moisture is too high.

|

|

|

|

|

||||

|

Tail belt sweeper

|

|

|

|

|

||||

|

Hardness of cutter head

|

85-90shoreA

|

|

|

|

||||

|

Working temperature

|

40-71℃

|

|

|

|

||||

|

Adapted belt speed

|

2~4.5m/s

|

|

|

|

||||

|

Adapted belt width

|

500-2200mm

|

|

|

|

||||

|

The tail belt sweeper is universally applicable for non working surface of belts.The special design of the suspension installation don not increase any pressure on non working surface so that protect belts and pulley from damage.It also has excellent cleaning performance.Tail belt sweeper is suitable for conveyor belts with cold and hot vulcanized joints and mechanical joints.There are two types of tail belt sweeper: V-type plough and diagonal scraper.

|

|

|

|

|

||||