NaN / 0

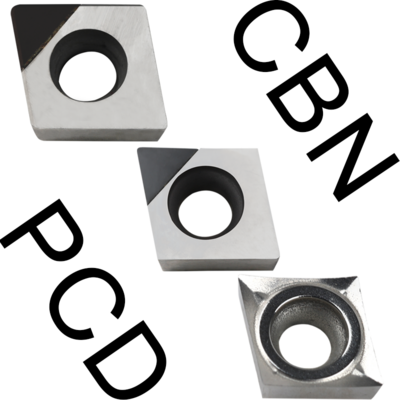

Cast iron processing CBN blade precision boring engine cylinder hole pcbn cutting tools

Get Latest Price

US$ 15

≥10 Pieces

US$ 11

≥10000 Pieces

US$ 3

≥1000000 Pieces

Quick Details

Use:

Internal Turning Tool

Hardness:

HB180-220

Coating:

Boron nitride

Place of Origin:

Henan, China

Product Details

Product Description

1.Products

(1)specifications

10 pieces/box

(2)Applicable scope

Processing cast iron/quenched steel

(3)Processing steps

Rough turning, fine turning

Processing conditions

Intermittent, continuous

(4)Blade advantages

High precision, ultra wear-resistant, impact resistant

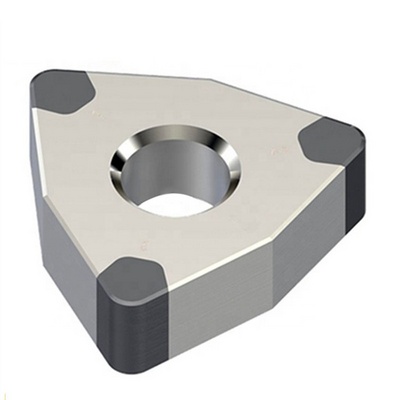

(5)product type

CNC Indexable Blade

(6)Sellable land

global

(7)material quality

Polycrystalline cubic boron nitride

(8)type

turning tools

(9)model

CNGN/SNGN

(10)China HS code

2.Drawing paper

| CUTTING TOOLS MATERIAL | Processing method | Withstand cutting depth | Cutting state | Recommended processing strength |

| BT2800 | Rough machining, semi precision machining | 1/3 Cutting edge length | Intermittent-- Continuous | HB180-220 |

| BT2900 | Precision machining | <0.5mm | Continuous-- interruption continuation | HB180-220 |

| BT9000 | precision machining | <1mm | Continuous-- interruption continuation | HB180-220 |

Case1

Rough milling of the top surface of the engine cylinder block

Material:Gray cast iron HB180-220

Recommended cutting tools:BTS2805 SNFN1206012

Cutting parameters:as following picture.

Case2:Precision milling of the bottom and top surfaces of the engine cylinder block

Material:Gray cast iron HB180-220

Recommended cutting tools:BT2800 SNFN120408

Cutting parameters:as following picture.

Precision boring of engine cylinder holes

Material:Gray cast iron HB180-220

Recommended cutting tools:BT9000 TCGW110304-F

Cutting parameters:as following picture.

Three kind engine cutting case as following:

3. Advantages of PCBN

(1)High hardness, good wear resistance, and high temperature resistance.

PCBN can easily process more over HRC55 hard steel material,There will be no rapid wear or breakage of the blade caused by high temperature, and the tool life is 3-5 times longer than that of hard alloy blades and coated blades

(2)Strong resistance

When processing certain hard workpieces, there may be intermittent cutting conditions, and conventional cutting tools are prone to tool breakage and poor impact resistance. PCBN's BTS6000A material, made of metal binder, has strong impact resistance and is less prone to tool breakage, resulting in more reliable quality

(3)High precision and good consistency

For hard steel workpieces with high requirements for surface smoothness and dimensional accuracy, hard alloy cutting tools require frequent tool changes to achieve processing requirements. PCBN blades use turning instead of grinding technology in the cutting process of black metal processing, resulting in high precision and smoothness of the processed product, good dimensional consistency, and small shape errors. Moreover, PCBN blades belong to the category of indexable multi blade blades, which have high indexable accuracy, reduce tool setting time and tool change frequency, and improve processing efficiency.

(4)Suitable for high-speed cutting

PCBN tool is an ideal tool for mass production of hard steel parts on fully automatic assembly lines, capable of withstanding high temperature, high speed, intermittent and other working conditions. The PCBN blade made of bts6000 material has a maximum linear speed of 2000M/min, which can greatly improve processing efficiency and achieve better turning performance for hard steel parts.

4.Material grade

The material grade contain the BT2000,BT2800,BT2800A,BT280S,BT2900,BT6000,BT6000-A,BT6600,BT6800,BT7800,BT9000,

Different kinds material has different CBN,and mesh is different,of course it will used in different parts cutting.

Contact us to check more.

5.Main model

Outside of different model as followings,It has CNGN,DNGN,SNGN,SCGN,TNGN,RCGV,RCGX,SCGW and so on,check the pictures following.

6.Case

(1)Cast iron parts

(2)Hard steel parts

(3)Wear resistant parts

6.Two steps for selecting a cutting tool

(1)Select the appropriate grade based on the processing materials

(2) select the tool parameters for the processing conditions.

7.Factory directly selling;

Some photos of the factory

8.The last most important thing about price.

Most important thing about price

Most important thing about price

Most important thing about price.

The last most important thing is the price.

For we need to confirm the material PCBN you need,and also need to confirm what part you will need to cut,so there are hundreds of models.

Also different country has different freight ,so just mail to us or add our whatsapp to talk online.

So all price in our web is not the final price,every customer has different needs,give us the mail or whatsapp to get your price.

If pay without comunicate with us,we will not send out the goods.

The min order is 10 pcs,the price is also 10 pcs total price,which we also called one set price.

Confirm to pay before to confirm everything specials.

Packaging & Shipping

The min order is 10pcs,send by UPS,DHL,TNT,FEDEX AND SO ON.

Less than 50kgs or 100kgs also can send by express.

More than 100kgs will send by sea or by railway.