NaN / 0

coconut oil refining machine waste oil to diesel fuel refinery heavy oil refinery thin film method

Get Latest Price

US$ 7800

≥1 Sets

US$ 7506

≥5 Sets

Quick Details

Max Capacity:

10T/D

Production Capacity:

90%

Place of Origin:

Henan, China

Brand Name:

Mingxin

Product Details

Product Description

coconut oil refining machine waste oil to diesel fuel refinery heavy oil refinery thin film method

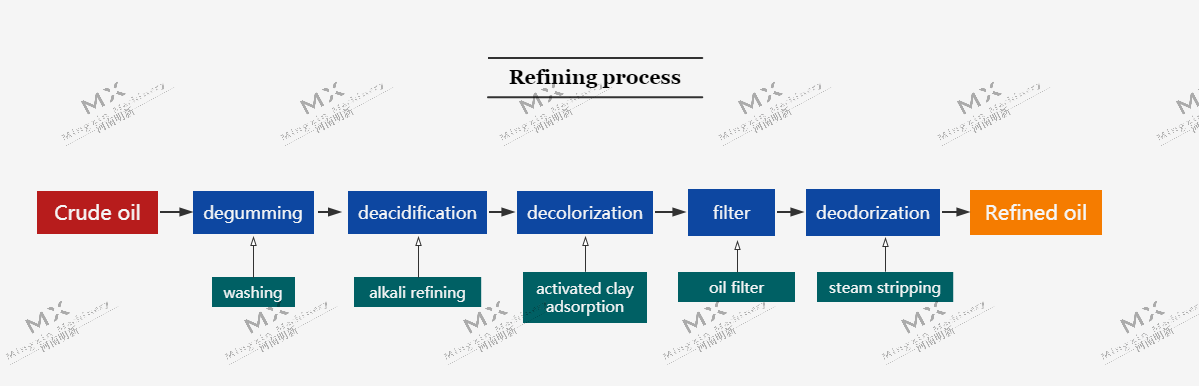

Crude Oil is mainly further processed into edible oil for food purpose. To meet the international industry’s standards for edible oil, the crude oil produced by oil mills should be refined in oil refinery plant. oil refinery process mainly includes oil degumming, oil deacidification, oil bleaching and oil deodorization. .

Why is edible oil refined?

The refining process removes water, odouriferous matter, phosphatides, free fatty acids and other impurities including dirt and traces of metals from oil mill. After processed in oil refinery plant, the final oil product is a kind of premium edible

oil of consistent quality which not only satisfies customer requirements and industry’s standards in respect of Iodine Value, FFA, flavor, color, melting point, peroxide value, impurities and moisture.

The refining process removes water, odouriferous matter, phosphatides, free fatty acids and other impurities including dirt and traces of metals from oil mill. After processed in oil refinery plant, the final oil product is a kind of premium edible

oil of consistent quality which not only satisfies customer requirements and industry’s standards in respect of Iodine Value, FFA, flavor, color, melting point, peroxide value, impurities and moisture.

Specification

5T Per batch palm oil refining machine

vary in capacity, size and price. Tell us the daily processing capacity and refining process you need, we will introduce the most suitable model for you, and can also be customized according to your specific needs.

|

Model

|

MX-2

|

500L

|

1000L

|

|

Power

|

24KW

|

18KW

|

42KW

|

|

Daily Capacity

|

300-600L

|

300-600L

|

1000-2000L

|

|

Tank Volume

|

2000*900*2250mm

|

3120*830*1550mm

|

4300*900*2300mm

|

|

Weight

|

400kg

|

280kg

|

1350kg

|

|

Size

|

380V/50Hz

|

380V/50Hz

|

380V/50Hz

|

Note: The weight, shape and some parameters of the machine are constantly adjusted with the technical upgrade. The material object shall prevail

Working Principle

Basic Steps of

5T Per batch palm oil refining machine

process

*

Step 1:

Remove the easily hydratable phospholipids by degumming with water.

* Step 2 : Convert the remaining on-hydralable phospholipids into hydratable phospholipids.

* Step 3: Adding a slight excess of sodium hydroxide solution to neutralize the free fatty acids. Then, wash out the hydrated phospholipids and soaps;

* Step 4: Bleaching with natural or acid-activated clay minerals to adsorb colouring components and to decompose hydroperoxides.

* Step 5: Remove volatile components through steam distillation process under elevated temperature (180-220°C) and low pressure

coconut oil refining machine waste oil to diesel fuel refinery heavy oil refinery thin film method

Product Show

coconut oil refining machine waste oil to diesel fuel refinery heavy oil refinery thin film method

Application

Scope of application of

coconut oil refining machine waste oil to diesel fuel refinery heavy oil refinery thin film method

:Vegetable oils:

palm oil, coconut oil, peanut oil, soybean oil, canola oil, avocado oil, sunflower oil,

tea seed oil, peony seed oil, perilla seed oil, flax oil, grapeseed oil, safflower oil, mustard seed Oil, Mango Oil, Pomegranate Seed Oil, Pumpkin Seed Oil, Walnut Oil, Moringa Seed Oil, Hazelnut Pine Nut Oil, etc.

Package&Delivery

5T Per batch palm oil refining machine

show

1. Packaging and Shipping: The products are packed in wooden boxes after film wrapping and shipped in 20ft containers/40ft containers. We can help customers to ship

2. Production: After receiving the customer's deposit, arrange production. We can ship within 7-10 days after receiving the banlance payment

Company Introduction

Our company insists on the professional development based on the principle of innovation and honesty. We win the market with our advanced skills, high-quality products and considerate services.The products in our company have been exported to the South Africa, Pakistan, Vietnam and other counties with the advanced technology, reliable quality and reasonable price. We have also got the good reputations from customers at home and abroad.

Our Service

Our Service

1.

Can be customized according to customer needs.

2. Check again before we send the goods.

3. Send the goods on time.

4.One year warranty from the date of receiving.

5. We can test the machine before we send it if the client need.

6. The more you need, the cheaper the unit price is.

7. Help the client with the shipment

Hot Searches