NaN / 0

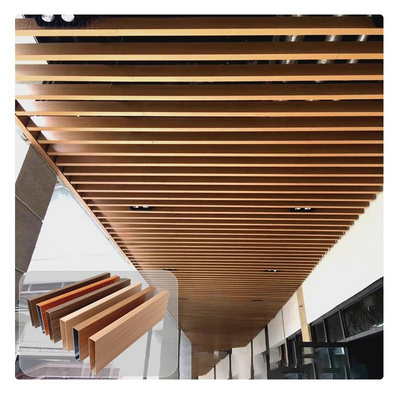

Low Price Aluminum Wooden Grain Linear Baffle Ceiling Decorative Metal Strip Aluminum Ceiling

Get Latest Price

US$ 3.76

≥500 Kilograms

US$ 3.28

≥2000 Kilograms

US$ 2.89

≥10000 Kilograms

US$ 1.38

≥3000000 Kilograms

Quick Details

Warranty:

1 Year

After-sale Service:

Online technical support, Onsite Installation

Project Solution Capability:

3D model design

Application:

Hotel

Product Details

Product Description

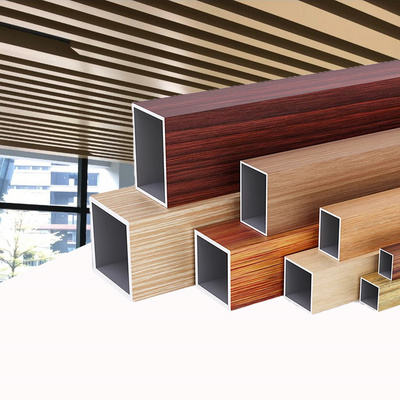

Low Price Aluminum Wooden Grain Linear Baffle Ceiling Decorative Metal Strip Aluminum Ceiling

|

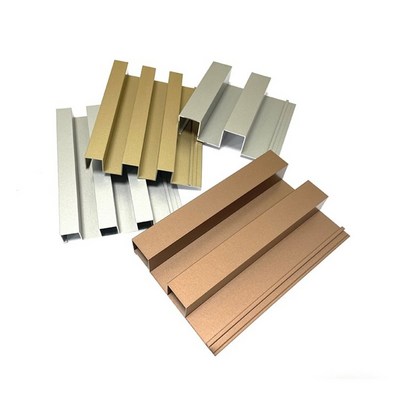

Product Name

|

Aluminum Ceiling Wall Profile

|

|

Material

|

Aluminum Alloy

|

|

Advantage

|

Flexible/High-end/Corrosion Resistant/Light Weight

|

|

Package

|

Customized

|

Related Products

Company Introduction

Kaiya has more than 20 years and wins the reputation of "Guangdong Famous Aluminum" and "China Excellent Manufacturer".

We specialized in Aluminum window and door, Aluminum curtain wall and sliding , Aluminum roller shutter slat and louver, Aluminum cabinet and wardrobe, Aluminum decorative, Aluminum led light bar and Heat Sink, tube,industrial Aluminum etc.

We specialized in Aluminum window and door, Aluminum curtain wall and sliding , Aluminum roller shutter slat and louver, Aluminum cabinet and wardrobe, Aluminum decorative, Aluminum led light bar and Heat Sink, tube,industrial Aluminum etc.

Certifications

FAQ

Q1:What is aluminum extrusion, fabrication, and anodization?

A: Aluminum Extrusion refers to a process of creating shapes with an aluminum billet or log by forcing it to flow through a shaped opening in a die. Aluminum can be extruded into standard shapes or specific designs depending on a customer’s preference. Fabrication refers to building aluminum components by cutting, drilling, slotting, tapping,bending, CNC machining, mechanical assembly and welding. Anodization is an electro-chemical process of coating aluminum with a thin layer of oxide to increasecorrosion resistance and harden the surface.

Q2: What’s the thickness for anodizing? Can you do 15um?

A: Our normal thickness is about 10 um. Yes, we can do 15um and above.

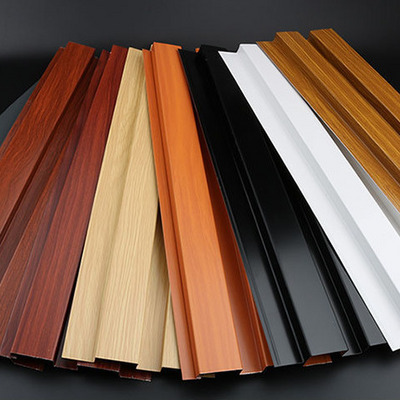

Q3: What color you can do for powder coating? The thickness for powder coat?

A: We can do any color for powder coat as long as you can provide the color sample. Our normally powder coating thickness is60-80um.

Q4: What color you can do for wood grain?

A: Our most popular colors are Western Red Cedar, Australia Cedar, Jarrah I, Jarrah II, Chestnut, Bush Cherry, Bush Wood, Western Wood, Snow Gum, etc. If you need any other colors, we can do according to the color samples you provide.

Q5: What’s the delivery time for samples and mass production?

A: (1). 7-15 days open the new moulds and make samples.

(2). 15-28 days after received deposit and confirmation of the order.

A: Aluminum Extrusion refers to a process of creating shapes with an aluminum billet or log by forcing it to flow through a shaped opening in a die. Aluminum can be extruded into standard shapes or specific designs depending on a customer’s preference. Fabrication refers to building aluminum components by cutting, drilling, slotting, tapping,bending, CNC machining, mechanical assembly and welding. Anodization is an electro-chemical process of coating aluminum with a thin layer of oxide to increasecorrosion resistance and harden the surface.

Q2: What’s the thickness for anodizing? Can you do 15um?

A: Our normal thickness is about 10 um. Yes, we can do 15um and above.

Q3: What color you can do for powder coating? The thickness for powder coat?

A: We can do any color for powder coat as long as you can provide the color sample. Our normally powder coating thickness is60-80um.

Q4: What color you can do for wood grain?

A: Our most popular colors are Western Red Cedar, Australia Cedar, Jarrah I, Jarrah II, Chestnut, Bush Cherry, Bush Wood, Western Wood, Snow Gum, etc. If you need any other colors, we can do according to the color samples you provide.

Q5: What’s the delivery time for samples and mass production?

A: (1). 7-15 days open the new moulds and make samples.

(2). 15-28 days after received deposit and confirmation of the order.

Hot Searches